On Saturday we had my dad's funeral. It was a nice event. The goal was to celebrate his life, and the faith in the resurrection and ongoing phases of life after this mortal phase. We had some musical numbers, a few grand daughters either gave remembrances of him or read things he had written (he was a blogger and also wrote some books about his life and also about his beliefs). I and my siblings spoke about our remembrances.

Then there was a simple graveside service (dedication of the grave) and after that a luncheon for family, where we talked about my dad and also talked with family members we had not seen in a while, etc.

My brother and his family had come up from Arizona -- flown into the small Provo airport on Friday morning and left from same Sunday evening. I picked them up and dropped them off. I'd ever been to this airport -- it is a regional one with mostly general aviation but does have Allegiant and Breeze Airways passenger services.

My sister who is in Africa with her family but had been here for a summer break left today to go back to Africa, as planned. All in all the timing of everything worked out for the best.

--

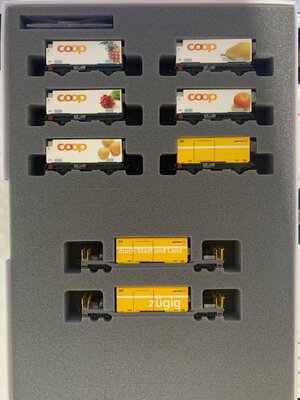

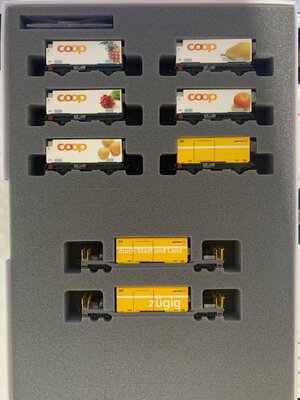

Today I got a package via Fedex from Japan. When the company I work for got bought out we got our stock units accelerated and we had a good amount of bonus cash in Feb. I got permission from my better half to get a couple of train things that were being released this year. Some were in stock things and some were pre-orders. The dealer in Japan held the in stock stuff for me (once paid for) and when the other stuff came in over the last couple weeks, and was paid for, he then sent it to me. He just sent it Friday Japan time and I already got it. And the Fedex cost for 5.5 lbs was less than US$ 30, which was slightly more than half of the DHL cost. (Part of this is the strong dollar at the moment which made everything actually be pretty inexpensive).

This is KATO stuff but is for the Swiss narrow gauge railway Rhaetian Railway or Rhätische Bahn. I have a few locomotives and passenger wagons already for it and added to that with some new locomotives, an open panoramic car, a luggage wagon, and a set of flat cars with containers. Reefer contains from a store in Switerland call Co-op and then Swiss Post containers.

fb.watch

fb.watch