GuilfordRailman

Well-Known Member

Hello Everyone!

Model railroading had been put aside the last few months except for some minor Lionel train set work.

Last week I received an email inviting me to exhibit a layout at a local train show! This brought back some motivation to build another layout

Now…since my n scale layout was sold two months ago (unfortunately) I didn’t have a layout to display and will need to build one. The show has some space available for 6 ft folding tables and therefore will limit my choices for a design!

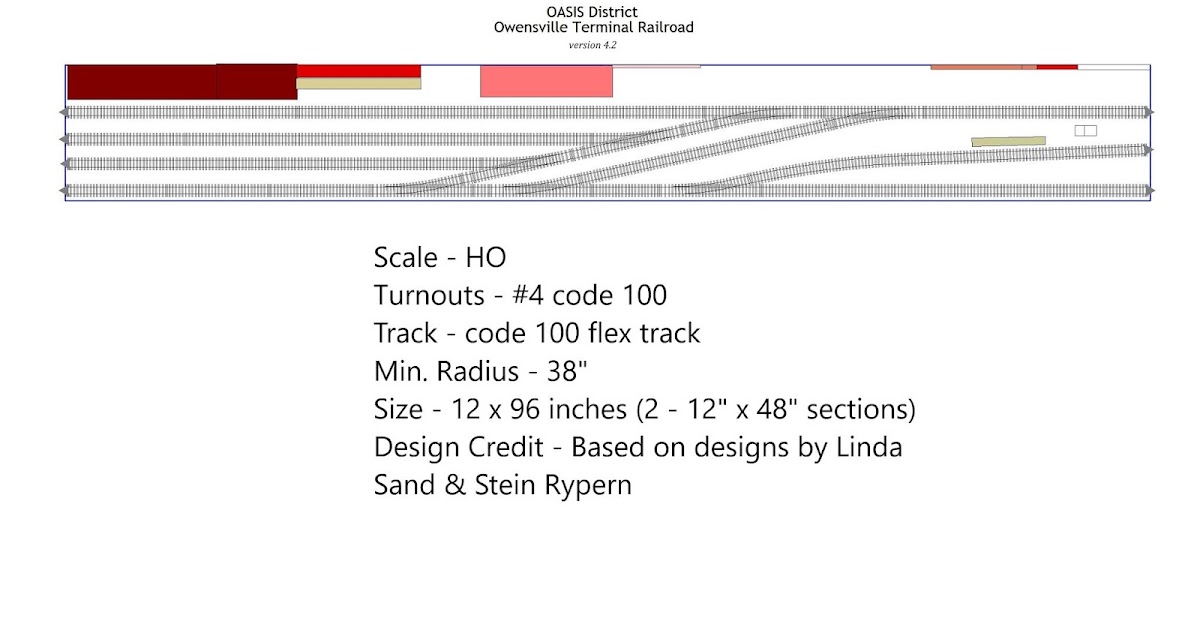

However…I like a challenge! That being said, I plan to build a 1 ft x 6.5 ft shelf switching layout in HO scale. Yes, operations will be limited, but…I love micro-layouts and switching cars so it’s the perfect size for me Plus, 6.5 ft is about as much space as I have available haha.

Plus, 6.5 ft is about as much space as I have available haha.

I have until October 28th to complete the build which isn’t very long so work will be getting started very soon! Looking forward to sharing my build progress.

Model railroading had been put aside the last few months except for some minor Lionel train set work.

Last week I received an email inviting me to exhibit a layout at a local train show! This brought back some motivation to build another layout

Now…since my n scale layout was sold two months ago (unfortunately) I didn’t have a layout to display and will need to build one. The show has some space available for 6 ft folding tables and therefore will limit my choices for a design!

However…I like a challenge! That being said, I plan to build a 1 ft x 6.5 ft shelf switching layout in HO scale. Yes, operations will be limited, but…I love micro-layouts and switching cars so it’s the perfect size for me

I have until October 28th to complete the build which isn’t very long so work will be getting started very soon! Looking forward to sharing my build progress.