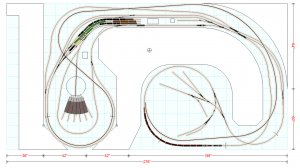

Bob, looking at your last plan, and assuming they are 12" squares in the graph, then you have allowed 20' as the length of the layout. The measurements of the room that Greg showed back if Page7, post #67 works out to 22'5", give or take.

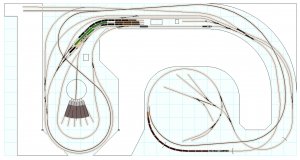

I haven't bothered showing the along the wall staging, as there is nothing to design. You put in as many parallel tracks as you have room for, and connect to them to the main layout at the upper left. It is definitely needed, and important, but not something that has to be including in my design doodles.

While the plan is to scale, it's still only a schematic. Nothing shown in "cast in concrete", it's just the overall concept. Need more aisle width? Shrink down the peninsula a bit and tighten up the curves. I think the inner one is at 32" right now, it could easily be shrunk to 29, and that would give you 6 inches less width. The roundhouse is a pure guess on my part and I've drawn it big. It may end up smaller, but he said "big engines".

Here's my concept of how this will play out for Greg.

I'd start with the staging on the left, make it as wide as you comfortably can. Then lay out the two "bubbles" and connecting benchwork, using butcher paper on the floor (normally I'd just use chalk, but he just did that gorgeous floor and I wouldn't want it to leave any marks). Then, once you've got that done, look at the aisle ways. Are they comfortable? Do you have enough room? Once you like it, the benchwork gets built.

Then you look at my sketch, which is just that, a sketch, and do one of two things:

1) Say "This guy's an idiot! I want the yard over THERE, not here!" and totally ignore what I drew.

2) Say "OK, I like this idea, let's try and go with something along those lines." You draw in the curves first, as they're pretty much locked in. Then you lay out the yard tracks using switches to see what fits. Then you look at the space left and put whatever you want wherever you want it. The sidings and even the alignment of the main tracks are purely rough ideas. Also, as mentioned, they would look better with some gentle curves and twists. So, once you pencil out where the switches go, get creative, do what you want. The fact that I drew a 37.81 inch radius curve with an angle of 87.92 degrees is meaningless.

Without an actual and accurate measurement of the room, my plan is only good for a guide. So why bother doing it at all? Well, because it's too easy to draw stuff that won't fit, especially switches. So while they may not go exactly where I drew them, the amount of space they'll take up is pretty close, and that's useful in the planning stages.

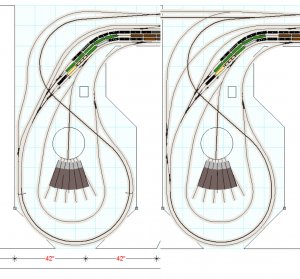

Double level staging as you have suggested would also have distinct advantages space wise.

Yes, and it's easy enough to do. Have one come off the lower level and one come off the highline. You'll probably only get 6 inches or so of height, but for a shallow track that's just staging, it will work. (Yeah, I know, when something on the back track in the bottom derails, he's going to be grumpy, but hopefully it doesn't happen too much. If you have enough height, maybe the top can go on a 1 x 12 designed to be removable.

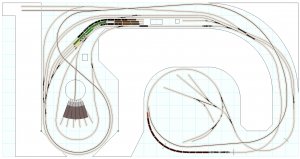

I like the addition of the extra hi-line, it creates new visual elements and reinstates in a better manner, my bridge (or more bridges) across the yard/s, but in a better location. (top marks for that).

Cool, thanks, glad you like it.