Sawman,

Just to follow up on a few subjects:

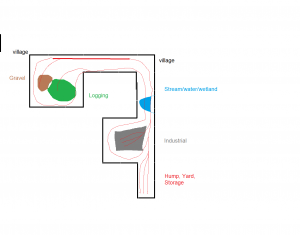

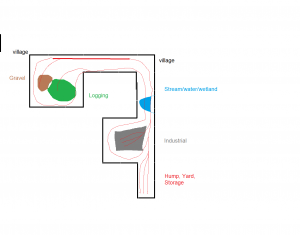

1)Hump Yard-You might try and find the website for the Pacific Southern, in Rocky Hill, NJ(outside of Princeton). Last I was there, they also had an operational hump yard at one end of the layout. Having seen this one and the one in Carlstadt I previously mentioned, operate, I generally tend to agree with others, that the cars typically roll downhill at breakneck speed, and slam into the car ahead, when coupling. I've seen the Carlstadt group try to decelerate the cars using air, on at least 2 layouts now. If you have a limited number of cars, and knew all of their weights, and rolling characteristics, you might be able to control them reliably, but it could take years. Also, the bowls generally are only 4-6 tracks on the layouts I've seen, and the first switch after the hump is usually a wye, with a balanced ladder on each side.

Given your latest plan, I wonder whether you'll have enough room, for the hump and bowl, where you have it currently located. As someone else said, John Armstrong's book on track design, has a section on model hump yards, and a few comments. Don't forget, in the real world, the engines usually don't go over the hump and thru the retarders, to pull out a cut of cars. Mr. Armstrong's plan includes a 'hump cutoff track,' so the yard or hump engine doesn't have to pull the newly humped string, back over the hump in reverse, to move it to the departure tracks.

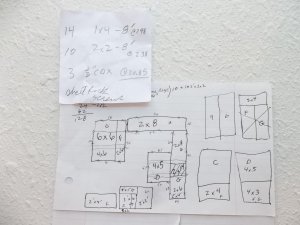

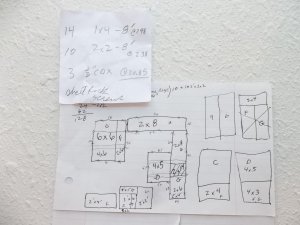

2)If for no reason other than scenery, you may wish to have some scenic features below grade, such as a pond, or river. This way, you can have a scene which includes a bridge or two. You may also want to trace the old sections of layout you plan on using on your new layout, and cut these areas out, using something like a jig or sabre saw. You could them shim them to the right height. FWIW, I built a 24' x 18' layout several years back, mainly relying on a sabre saw, and variable speed drill. This time around, I've added a circular saw to my tools, to move things along faster.

3)I've learned from experience that trimming a 45 degree section of the table corner, with the two legs of the triangle being say 4", will add just a bit of aisle width, which will be helpful when you have others over. You also reduce 'pinch points,' or corners which you can get caught on, when you're in a hurry. You loose some space for scenery, but will make it easier to get around the layout. If you plan it right, you could use these triangles to fill in the interior of 90 degree turns in the table, where a curve might get very close to the inside corner of the layout.

Hope this helps!

Otis