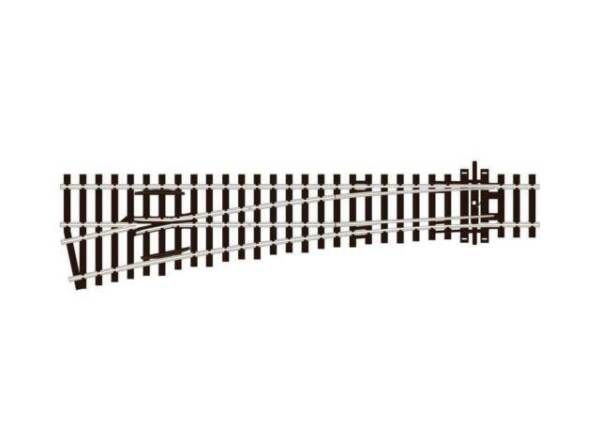

BEWARE of how you install Peco turnouts

I think many of us are aware of the problems that can arise when the wheels of our locos bridge the 2 rails exiting the frogs of turnouts,...or at least many of us WILL BECOME aware.

I've utilized almost all insulfrog Pecos on my layout,..and I had been convinced by many forum members that providing insulators on those 2 tracks exiting the frogs were not always needed, .....particularly where the gap between those frog rails appeared to be large enough to not cause a shorting problem.

I HAVE EXPERIENCED THE OPPOSITE,...they are all necessary !

I wired up my whole layout for DCC operation, but before I hooked in the DCC power, I hooked up multiple DC transformers to see if I had done it properly. YES, everything was working just fine on DC,..no shorts, even the revers-er sections OK .

Then I hooked in my DCC power to the lower deck,...AND began to experience numerous mini-stalls/tripping of the DCC Specialities circuit protection boards !!

I ran 7 different type locos (diesel and steam) over these problem areas,....some made it thru the gauntlet,..most did not. Turns out it was not a specific wheel problem, it was that MOST wheels would short out on those frog rails.

I have spent the last 2 days going back and cutting insulation gaps in those Peco turnouts. Now things are working very smoothly with no stalling/shorting.

I think many of us are aware of the problems that can arise when the wheels of our locos bridge the 2 rails exiting the frogs of turnouts,...or at least many of us WILL BECOME aware.

I've utilized almost all insulfrog Pecos on my layout,..and I had been convinced by many forum members that providing insulators on those 2 tracks exiting the frogs were not always needed, .....particularly where the gap between those frog rails appeared to be large enough to not cause a shorting problem.

I HAVE EXPERIENCED THE OPPOSITE,...they are all necessary !

I wired up my whole layout for DCC operation, but before I hooked in the DCC power, I hooked up multiple DC transformers to see if I had done it properly. YES, everything was working just fine on DC,..no shorts, even the revers-er sections OK .

Then I hooked in my DCC power to the lower deck,...AND began to experience numerous mini-stalls/tripping of the DCC Specialities circuit protection boards !!

I ran 7 different type locos (diesel and steam) over these problem areas,....some made it thru the gauntlet,..most did not. Turns out it was not a specific wheel problem, it was that MOST wheels would short out on those frog rails.

I have spent the last 2 days going back and cutting insulation gaps in those Peco turnouts. Now things are working very smoothly with no stalling/shorting.