N

NP2626

Guest

How is it that the Standards are felt to be mystifying? As stated in the first Video "Demystifying the NMRA Standards" That has not been my experience and to the contrary, the Standards clarify; or, explain what it is I need; or, want to understand! Possibly not the video producers intentions; but, by stating "Demystifying the NMRA Standards", it appears they are saying they are the only person smart enough to clarify these confusing standards.

I know, I've read far more into what is intended. However, I enjoy looking at how things get worded. "Turnouts and the NMRA Standards" would be a better choice of verbiage!

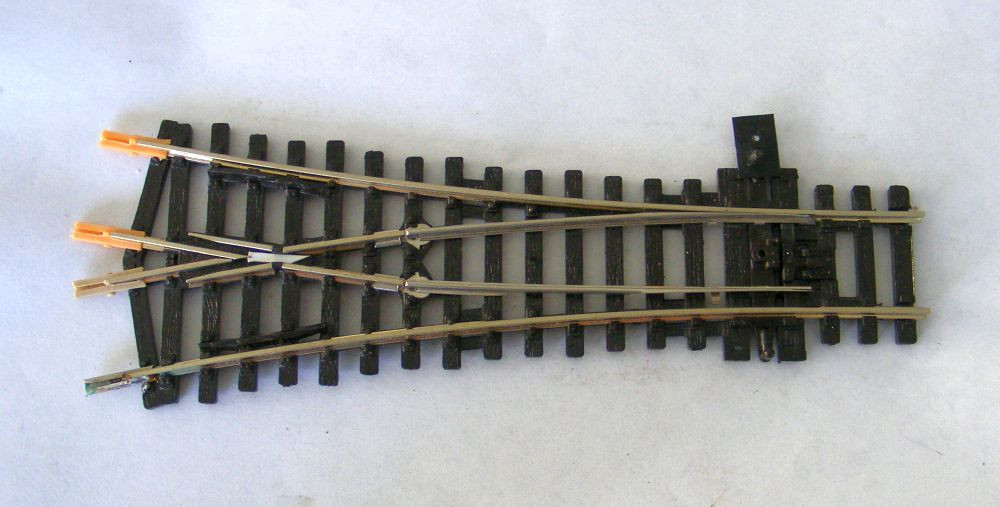

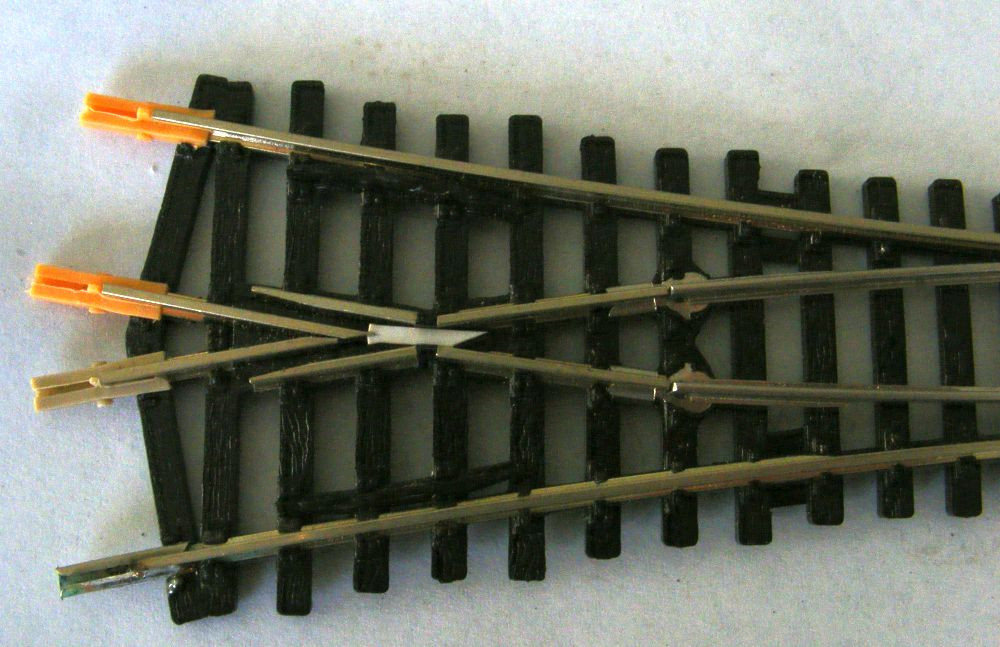

I know, I've read far more into what is intended. However, I enjoy looking at how things get worded. "Turnouts and the NMRA Standards" would be a better choice of verbiage!

Last edited by a moderator: