You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dave's Layout v. 4.0

- Thread starter logandsawman

- Start date

ModelRailroadForums.com is a free Model Railroad Discussion Forum and photo gallery. We cover all scales and sizes of model railroads. Online since 2002, it's one of the oldest and largest model railroad forums on the web. Whether you're a master model railroader or just getting started, you'll find something of interest here.

I was actually able to get a coat of hydrocal down last night while waiting for supper

It is going much quicker now that I've had lots of practice

Just like about everything, by the time I am done, I know what I am doing

That is why the initial measurement is so important.

Also, doing a large batch doesn't help, unless maybe doing a large simple area where you can pour it out rather quickly.

Once I got the knack of it, however, I would not dream of using another product.

It sets up hard in about an hour or less, and doesn't shrink.

Affiliate Disclosure: We may receive a commision from some of the links and ads shown on this website (Learn More Here)

logandsawman

Northern Pacific history enthusiast

Thank you, 2 tracks;

I added the roof over the place where farmers would dump their grain, which is then augered to the silo, bins, or sheller/cleaner.

We had an elevator like this in my home town,

as a child I watched the operator open a couple steel doors at road level between the office and grain bins, trucks could dump their corn or whatever and there would be some internal system to get the grain in the right bin.

Dad said "don't go over there" as I stuck my head over the grates to see what was happening.

They had a roof over it.

I added the roof over the place where farmers would dump their grain, which is then augered to the silo, bins, or sheller/cleaner.

We had an elevator like this in my home town,

as a child I watched the operator open a couple steel doors at road level between the office and grain bins, trucks could dump their corn or whatever and there would be some internal system to get the grain in the right bin.

Dad said "don't go over there" as I stuck my head over the grates to see what was happening.

They had a roof over it.

logandsawman

Northern Pacific history enthusiast

Well I had a pretty good weekend in the train room, working the south end of the layout, some pics of my system for the landscape:

First I cut a piece of screen, or at least one side of it to attach to the track bed:

(above) this is a new system for me. The hot glue gun works nice, but requires patience. I will glue as much as I can hold in place, sometimes gently blowing on the glue to get it to set up enough to move on down the line. You can see from the photo I use ballast and nails to hold the track in place

(above) pretty much the same area as previous pic, got all the screen attached on the left side, then will trim with a scissors and glue the right side. I often get some interest in the terrain this way, here will be forming a ditch adjacent to the roadbed

(above) here the screen does not show up well, however I cover it with damp paper towels which provides a good base for the hydrocal. There will be a river where the towels end.

Ideally, I put the paper towels down and immediately apply hydrocal. I did not have time in this instance, so will apply hydrocal later. The 1x2 board is a placeholder for the bridge. The brown line tracts the approx path of the river, in the bottom center is a small island which will be covered with Silver maple trees, as the river has many islands like this where the current is slow.

(above) this area is ready to hydrocal. I was able to groove in a ditch on the right leading to the wall. The cereal box is the template for the access road to the freight yard, there will be a general store and cafe, a few small houses.

Thats all for now, feel free to comment or whatever

Thanks for looking, Dave LASM

First I cut a piece of screen, or at least one side of it to attach to the track bed:

(above) this is a new system for me. The hot glue gun works nice, but requires patience. I will glue as much as I can hold in place, sometimes gently blowing on the glue to get it to set up enough to move on down the line. You can see from the photo I use ballast and nails to hold the track in place

(above) pretty much the same area as previous pic, got all the screen attached on the left side, then will trim with a scissors and glue the right side. I often get some interest in the terrain this way, here will be forming a ditch adjacent to the roadbed

(above) here the screen does not show up well, however I cover it with damp paper towels which provides a good base for the hydrocal. There will be a river where the towels end.

Ideally, I put the paper towels down and immediately apply hydrocal. I did not have time in this instance, so will apply hydrocal later. The 1x2 board is a placeholder for the bridge. The brown line tracts the approx path of the river, in the bottom center is a small island which will be covered with Silver maple trees, as the river has many islands like this where the current is slow.

(above) this area is ready to hydrocal. I was able to groove in a ditch on the right leading to the wall. The cereal box is the template for the access road to the freight yard, there will be a general store and cafe, a few small houses.

Thats all for now, feel free to comment or whatever

Thanks for looking, Dave LASM

PRR Modeler

Well-Known Member

Everything looks great Dave.

logandsawman

Northern Pacific history enthusiast

Thanks, Curt.Everything looks great Dave.

I was actually able to get a coat of hydrocal down last night while waiting for supper

It is going much quicker now that I've had lots of practice

Just like about everything, by the time I am done, I know what I am doing

logandsawman

Northern Pacific history enthusiast

Put down some more hydrocal again last eve, the wife snapped some pics so you can see the process I use, also the consistency when I start putting it down. I have to work quickly, because towards the end it is stiffening in the bowl:

(above) I mix one batch at a time. The paper towels are dampened. This is addition to the work form the previous post.

(above) there is only a little in the bowl, that is all I do at a time. The spatula works for the initial smoothing. This batch was a little too thick to pour, ladeled it out with the spatula The cereal box is place holder for a road.

(above) After it is down, there is some time to smooth it out. Sometimes I only use the spatula, however if the consistency is right I can smooth it with my fingers at the end. Here you can see some of the ditch on the right of the tracks

(above) sometimes it is too sticky to smooth with the fingers, but this batch was perfect, I was able to get all the ridges out using a circular motion with my fingers.

Will be doing more filling in on the left side of track, however the right side is ready for a coat of paint and ground cover

Thanks for looking, feel free to comment

Dave LASM

(above) I mix one batch at a time. The paper towels are dampened. This is addition to the work form the previous post.

(above) there is only a little in the bowl, that is all I do at a time. The spatula works for the initial smoothing. This batch was a little too thick to pour, ladeled it out with the spatula The cereal box is place holder for a road.

(above) After it is down, there is some time to smooth it out. Sometimes I only use the spatula, however if the consistency is right I can smooth it with my fingers at the end. Here you can see some of the ditch on the right of the tracks

(above) sometimes it is too sticky to smooth with the fingers, but this batch was perfect, I was able to get all the ridges out using a circular motion with my fingers.

Will be doing more filling in on the left side of track, however the right side is ready for a coat of paint and ground cover

Thanks for looking, feel free to comment

Dave LASM

PRR Modeler

Well-Known Member

Great how to Dave.

2Tracks

Ol' School

Looking good Dave, coming along nicely,

I'm jealous Dave, I am so looking forward to the landscaping part of the build, when I get there! Anyway, I'm not familiar with hydrocal, could you wet your fingers/spatula, to help work it when it starts to set?sometimes it is too sticky to smooth with the fingers,

logandsawman

Northern Pacific history enthusiast

When it begins to set, that's it. I tried adding water, but whatever reaction that is taking place cannot be reversed, IMO.Looking good Dave, coming along nicely,

I'm jealous Dave, I am so looking forward to the landscaping part of the build, when I get there! Anyway, I'm not familiar with hydrocal, could you wet your fingers/spatula, to help work it when it starts to set?

That is why the initial measurement is so important.

Also, doing a large batch doesn't help, unless maybe doing a large simple area where you can pour it out rather quickly.

Once I got the knack of it, however, I would not dream of using another product.

It sets up hard in about an hour or less, and doesn't shrink.

logandsawman

Northern Pacific history enthusiast

Well, I finished the hydrocal around the freight house, started working on the river and the bank near Wyoming. All the screen is in place so mainly a matter of getting the hydrocal in place, getting down to the final leg!!

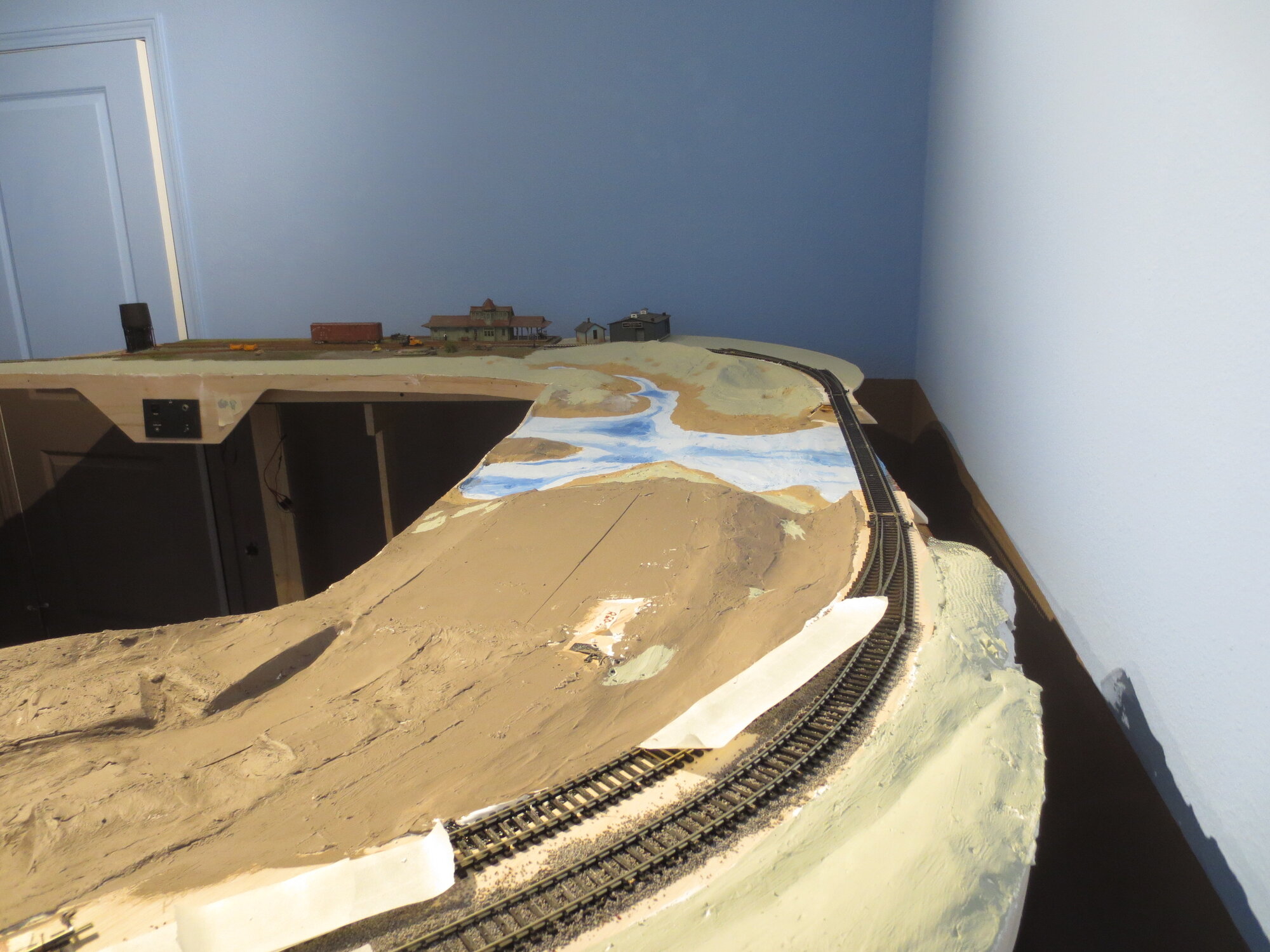

(above) the screen is all in place to the depot in the background. Also put in building pads between Groningen and the freight house. Working my way around to the other side

This area doesn't show up well due to the whites , however the riverbank is just about ready, and you can see paper towels in place where the next batch of hydrocal is going

I marked up this photo some, burgundy squares are pads for buildings, brown line is dead end road at freight house. Blue is the St, Croix river, a small tributary, and an island in the center. When I get these areas painted, it will make a lot more sense (I hope)

Currently also working on the track plan, where I can have locations of insulated joiners showing block sections.

Thanks for looking!!!

as usual, comments always welcome

Dave LASM

(above) the screen is all in place to the depot in the background. Also put in building pads between Groningen and the freight house. Working my way around to the other side

This area doesn't show up well due to the whites , however the riverbank is just about ready, and you can see paper towels in place where the next batch of hydrocal is going

I marked up this photo some, burgundy squares are pads for buildings, brown line is dead end road at freight house. Blue is the St, Croix river, a small tributary, and an island in the center. When I get these areas painted, it will make a lot more sense (I hope)

Currently also working on the track plan, where I can have locations of insulated joiners showing block sections.

Thanks for looking!!!

as usual, comments always welcome

Dave LASM

logandsawman

Northern Pacific history enthusiast

Thanks for all the people looking at my project, I am having a lot of fun also get to try some new things. I made a lot of headway over the weekend, pretty much one small area left to get the ground work/hydrocal done on.

First I would like to share my formula for the hydrocal. In the first image the exact measures I use to create a solid, strong, yet workable solution. I mixed up this exact pictured solution and it was like my third pour for the day. I probably mixed up 7 or more batches Saturday, sometimes I wait between batches 15 or more minutes where the screen base is stressing a little under the weight of the solution.

Start with these items:

The hydrocal is a heaping cupful, the water to the line. The plastic container has been used for the entire project. The big bowl holds all the waste when I clean out the bowl between batches. Can be broken up and used for stones, painted, etc. Or tossed.

(below) closeup of the cups

I pour the water in the small bowl, then sprinkle in the hydrocal slowly. You will have to look back to see how the screen looks and how I put the towels down, damp, then pour the solution on while it is still runny (not watery, however)

Here is the work I did over the weekend. Everything got painted and will get ground cover. Bridge is under construction:

Green and brown paint used, not fussy; mostly gets covered up. Haven't decided on technique to finish the St. Croix river, yet.

little different angle (above)

This is the other side of the layout. Put in some house pads by where the sawmill goes, also painted it all. Ready for ground cover/finishing/ballast.

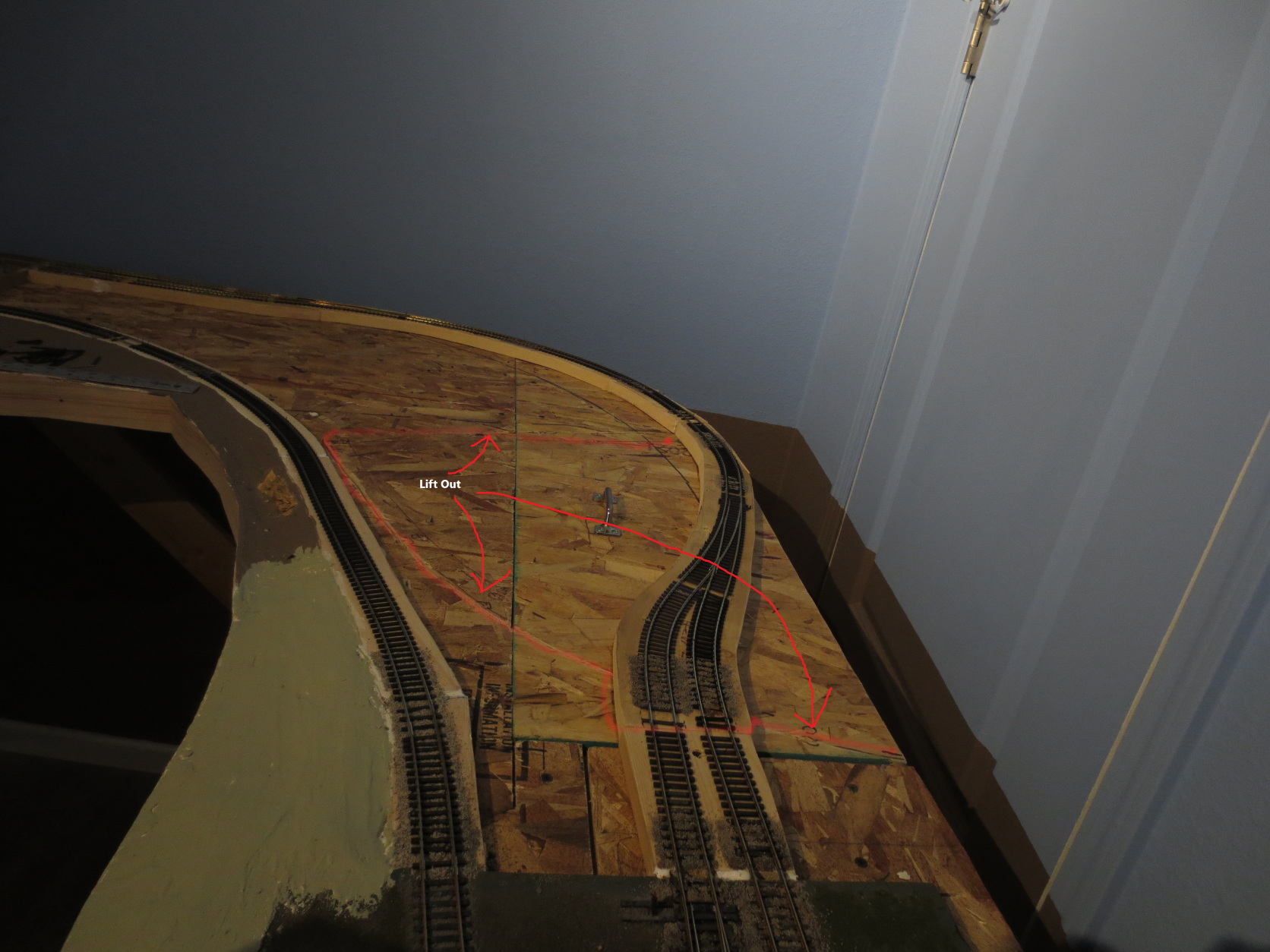

(above) the corner by the door is left to do, will be a lift out. May leave that for a while so I have easy access to the closet.

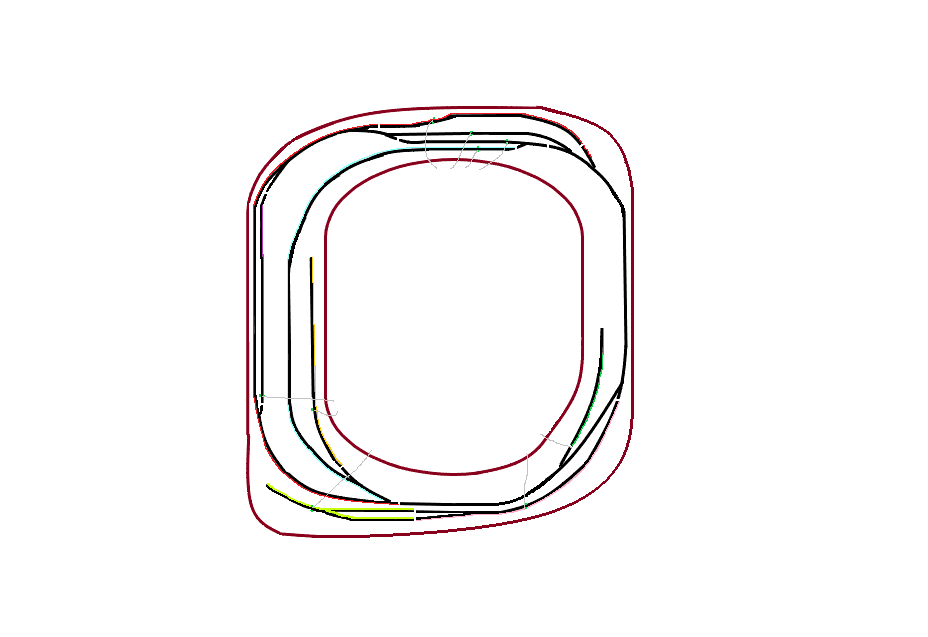

And finally, the track plan:

The gaps are insulated joiners, the light gray lines are switched power feeds.

Feel free to comment!! Thanks for looking,

Dave LASM

First I would like to share my formula for the hydrocal. In the first image the exact measures I use to create a solid, strong, yet workable solution. I mixed up this exact pictured solution and it was like my third pour for the day. I probably mixed up 7 or more batches Saturday, sometimes I wait between batches 15 or more minutes where the screen base is stressing a little under the weight of the solution.

Start with these items:

The hydrocal is a heaping cupful, the water to the line. The plastic container has been used for the entire project. The big bowl holds all the waste when I clean out the bowl between batches. Can be broken up and used for stones, painted, etc. Or tossed.

(below) closeup of the cups

I pour the water in the small bowl, then sprinkle in the hydrocal slowly. You will have to look back to see how the screen looks and how I put the towels down, damp, then pour the solution on while it is still runny (not watery, however)

Here is the work I did over the weekend. Everything got painted and will get ground cover. Bridge is under construction:

Green and brown paint used, not fussy; mostly gets covered up. Haven't decided on technique to finish the St. Croix river, yet.

little different angle (above)

This is the other side of the layout. Put in some house pads by where the sawmill goes, also painted it all. Ready for ground cover/finishing/ballast.

(above) the corner by the door is left to do, will be a lift out. May leave that for a while so I have easy access to the closet.

And finally, the track plan:

The gaps are insulated joiners, the light gray lines are switched power feeds.

Feel free to comment!! Thanks for looking,

Dave LASM

logandsawman

Northern Pacific history enthusiast

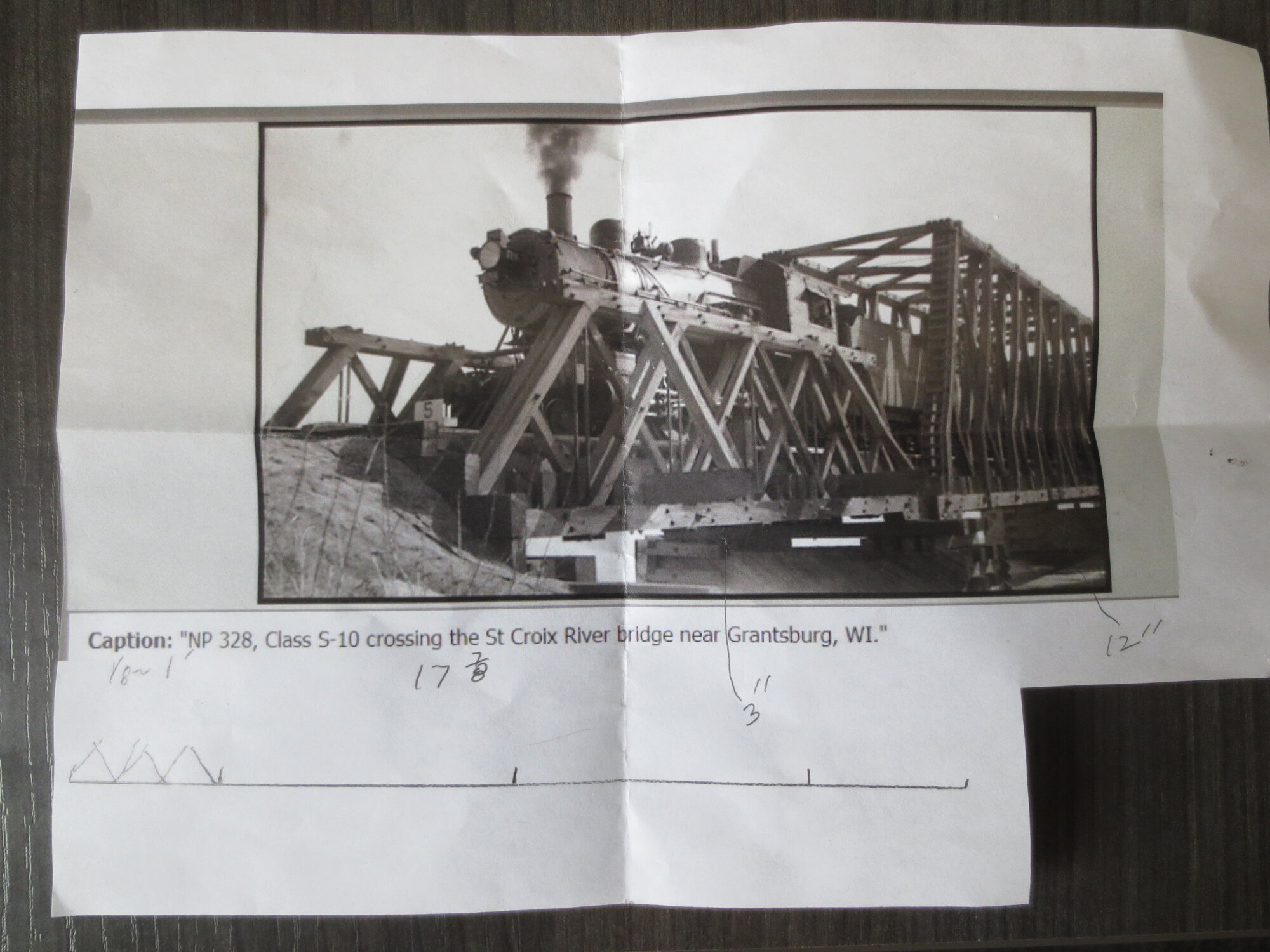

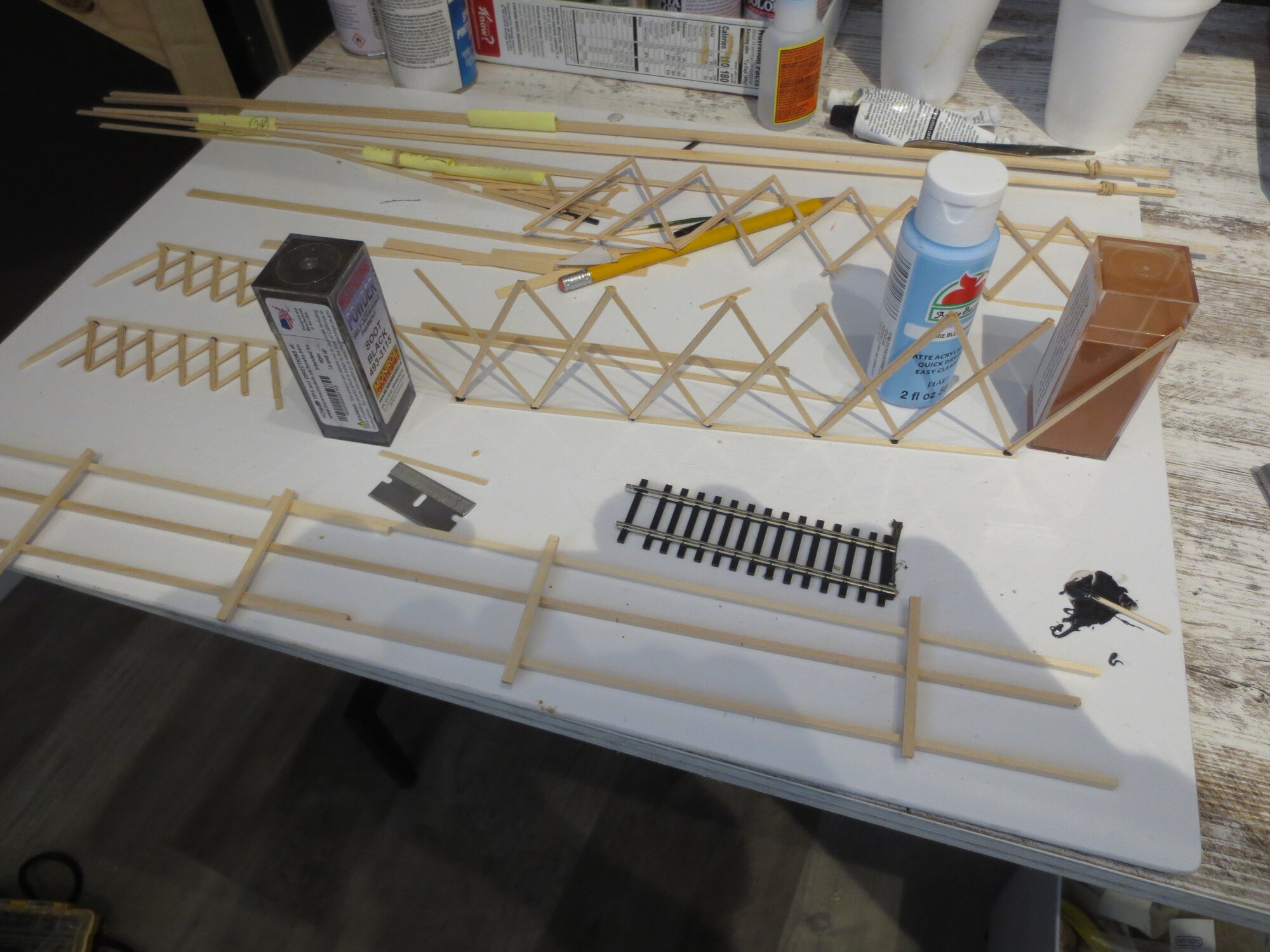

There a couple projects going on while I wait for some turnouts, first the bridge over the St. Croix river, which is a wood truss bridge:

I am working on reproducing this - roughly using the wood materials like the original, as well as some of the original architecture, the space is currently taken up by the pine 1 x 4 in the picture below:

The actual structure will only be about scale 2' below the ties, so will not be nearly as close to the water

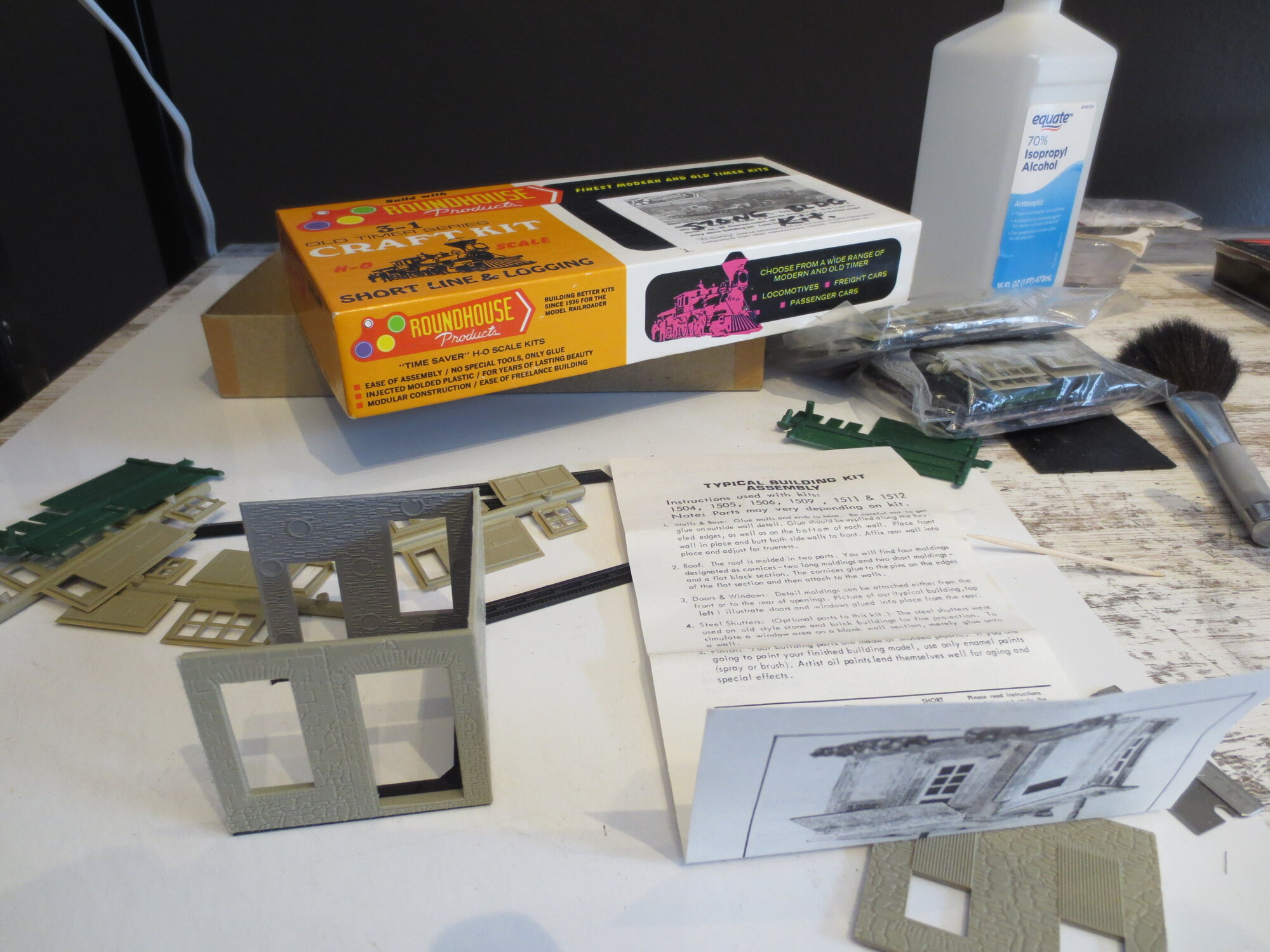

Also got these small structures from ebay, the old Roundhouse kit with several customizable buildings, the first one is helping me familiarize myself with some of the kits capabilities:

This is made for a 15 x 15 structure or a 15 x 30 larger structure, with water closet add-in suggested. The box came with 4 complete packets, not sure how they will all be used, but I really like the detail on the stone work

A long way to go on this one, looks a lot like the bank in Groningen so that may be its use. Otherwise, a small bunk room.

THANKS to all who look, leave a comment!

Dave LASM

I am working on reproducing this - roughly using the wood materials like the original, as well as some of the original architecture, the space is currently taken up by the pine 1 x 4 in the picture below:

The actual structure will only be about scale 2' below the ties, so will not be nearly as close to the water

Also got these small structures from ebay, the old Roundhouse kit with several customizable buildings, the first one is helping me familiarize myself with some of the kits capabilities:

This is made for a 15 x 15 structure or a 15 x 30 larger structure, with water closet add-in suggested. The box came with 4 complete packets, not sure how they will all be used, but I really like the detail on the stone work

A long way to go on this one, looks a lot like the bank in Groningen so that may be its use. Otherwise, a small bunk room.

THANKS to all who look, leave a comment!

Dave LASM

PRR Modeler

Well-Known Member

Great progress Dave.

logandsawman

Northern Pacific history enthusiast

I had a great weekend working on the layout, as the photos attest:

Got the lift out area just about completed, just have to fasten down track and ground cover

Here is the before pic (above), my turnouts to install

I used a piece of paper to draw out the curve, then cut it out of pine boards (above)

The section with lift out removed:

above - the track is getting figured out. The curve is the smallest on the layout, 20" radius. The inside track has a minimum 28"

Another shot. I wanted the maximum space open area between the two tracks for some scenes

THANKS to all who are looking!

Dave LASM

Got the lift out area just about completed, just have to fasten down track and ground cover

Here is the before pic (above), my turnouts to install

I used a piece of paper to draw out the curve, then cut it out of pine boards (above)

The section with lift out removed:

above - the track is getting figured out. The curve is the smallest on the layout, 20" radius. The inside track has a minimum 28"

Another shot. I wanted the maximum space open area between the two tracks for some scenes

THANKS to all who are looking!

Dave LASM

logandsawman

Northern Pacific history enthusiast

I got the track down on the new lift out section, ballasted several areas, will be inspecting, tweaking, and completing this week:

Lift out section marked out, look at previous posts for removed section. This allows access to closet.

THANKS for looking!!

Dave LASM

Lift out section marked out, look at previous posts for removed section. This allows access to closet.

THANKS for looking!!

Dave LASM

logandsawman

Northern Pacific history enthusiast

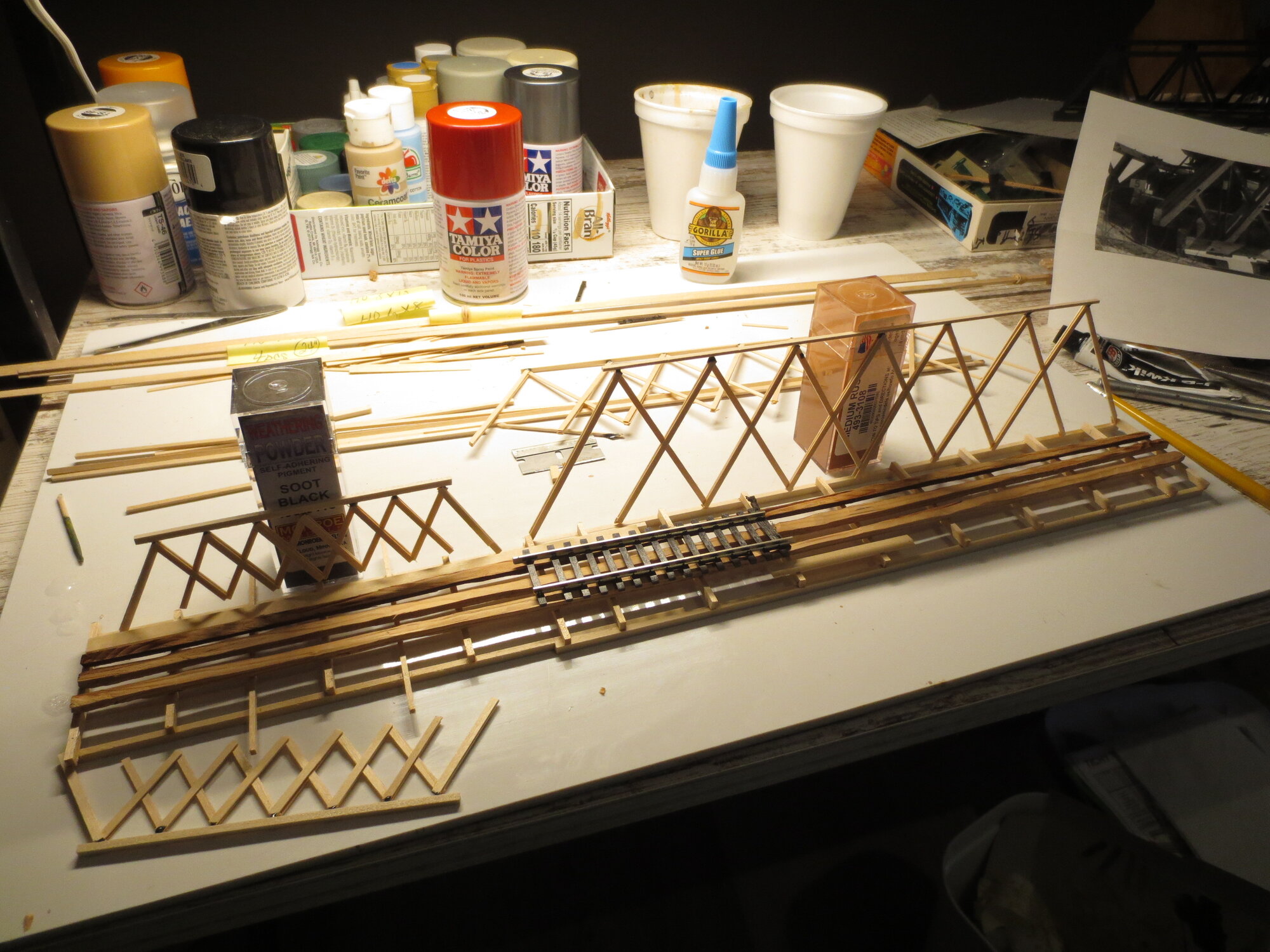

This weekend was catching up on some loose ends, back in post #112 I started on these, then put them on the shelf while getting the lift out done, now decided to revisit both the bridge and the small bank building (I think)

Decided to finish the bridge because the rest of the track work is ready to finalize & decided it would best to finalize the bridge project:

Shows some of the main components, the trusses. I used spots of JB Weld quick epoxy to adhere the top piece to the trusses, got it done on 3 of the sections. The long stringers are the base pieces, will be 3 layers of materials then track. Am building up the thickness of the trusses with successive layers of 2 x 8, similar to the prototype.

I think making the trusses is the hard part, here. May put in bolts, not sure if I will get that detailed.

The little building, I like how the paint turned out. The closeup shows small gaps in the walls I didn't previously notice.

Currently thinking this will be the bank building, looks a lot like the small one they had in Groningen.

may be a good place for it,

THANKS for looking, Dave

Decided to finish the bridge because the rest of the track work is ready to finalize & decided it would best to finalize the bridge project:

Shows some of the main components, the trusses. I used spots of JB Weld quick epoxy to adhere the top piece to the trusses, got it done on 3 of the sections. The long stringers are the base pieces, will be 3 layers of materials then track. Am building up the thickness of the trusses with successive layers of 2 x 8, similar to the prototype.

I think making the trusses is the hard part, here. May put in bolts, not sure if I will get that detailed.

The little building, I like how the paint turned out. The closeup shows small gaps in the walls I didn't previously notice.

Currently thinking this will be the bank building, looks a lot like the small one they had in Groningen.

may be a good place for it,

THANKS for looking, Dave

logandsawman

Northern Pacific history enthusiast

THANKS for looking! The lift out was easier than expected, maybe in part because it was designed before track laying.

Dave LASM

(Logan works, too)

Dave LASM

(Logan works, too)

logandsawman

Northern Pacific history enthusiast

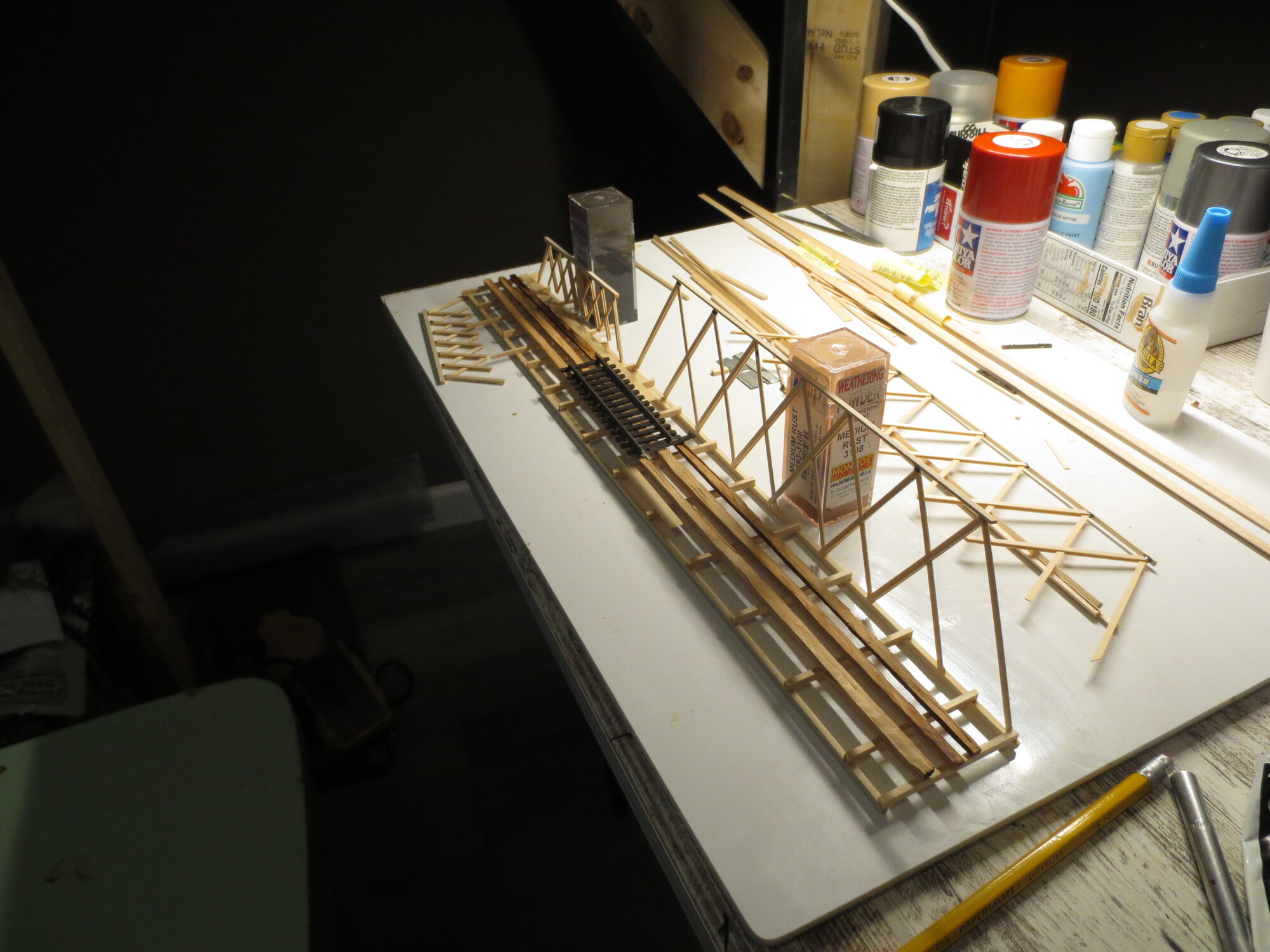

Working on the bridge, unbelievable how long it took me to get to this point, pic of the stringers at the proper length plus a couple cross pieces at the proper spacing:

The long supports are the anchor to supports for the short walls/trusses

This one shows more of the pieces. Also, the cleaned up work space and rearranged supplies.

I used the JB weld to attach some of the pieces, it is somewhat sticky when freshly mixed and can fill a small gap, unlike glue

All the cross pieces have been glued on, to fit where they belong below the trusses. The other wood is just placed on, not glued yet, to see how it is going to fit:

I will be building up the tall trusses a little by adding another set of 2 x 8's on top of the X's

The wide, flat boards will go alongside the track to make a walkway. Couldn't tell from the prototype pic how it looked inside the bridge

Getting close to paint, will prolly use some of the NutBoltWashers from Tichy to detail the woodwork.

You maybe noticed some of the home made scale lumber, that is Douglas Fir cut from some old boards around here, since the bridge is structural thought an improvement needed to upgrade the White pine/Basswood stripwood.

THANKS for looking and leave a comment if you like!

Dave LASM

The long supports are the anchor to supports for the short walls/trusses

This one shows more of the pieces. Also, the cleaned up work space and rearranged supplies.

I used the JB weld to attach some of the pieces, it is somewhat sticky when freshly mixed and can fill a small gap, unlike glue

All the cross pieces have been glued on, to fit where they belong below the trusses. The other wood is just placed on, not glued yet, to see how it is going to fit:

I will be building up the tall trusses a little by adding another set of 2 x 8's on top of the X's

The wide, flat boards will go alongside the track to make a walkway. Couldn't tell from the prototype pic how it looked inside the bridge

Getting close to paint, will prolly use some of the NutBoltWashers from Tichy to detail the woodwork.

You maybe noticed some of the home made scale lumber, that is Douglas Fir cut from some old boards around here, since the bridge is structural thought an improvement needed to upgrade the White pine/Basswood stripwood.

THANKS for looking and leave a comment if you like!

Dave LASM

Affiliate Disclosure: We may receive a commision from some of the links and ads shown on this website (Learn More Here)