Chef Waardevast

Member

Hello

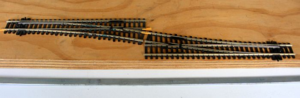

I hope you had a great thanks giving, I have a question regarding turnouts that I was hoping to get some advice. I just purchased the BLT PRR T1 4-4-4-4 and I am reconfiguring my layout to run it. I have one section of track that requires a turnout but I'm not sure given that it will be leading into a straight track whether it will make any significant difference what turnout size I use. I run peco code 100 streamlined and was going to use a 2nd radius left turnout as I have one spare. This equates to roughly 18" but we are only talking a very small turnout

Thanks in advance

I hope you had a great thanks giving, I have a question regarding turnouts that I was hoping to get some advice. I just purchased the BLT PRR T1 4-4-4-4 and I am reconfiguring my layout to run it. I have one section of track that requires a turnout but I'm not sure given that it will be leading into a straight track whether it will make any significant difference what turnout size I use. I run peco code 100 streamlined and was going to use a 2nd radius left turnout as I have one spare. This equates to roughly 18" but we are only talking a very small turnout

Thanks in advance