Chef Waardevast

Member

Hi thanks for the post, I was aware that articulated locos are designed to negotiate tighter curves, but I remember reading a post that the T1 made by BLT does not really work as well as a regular articulated loco because of reasons now that escapes me. The take home message was Byer beware when using the loco on tighter curves.Articulated locos should have less problems than locos with a number of big drive wheel all in a row.

Go to the peco website and get some FULL SIZE paper templates of their turnouts, then use them in your track planning.

I laid down some brown paper (like they use to protect floors during home/office-construction) and drew pencil lines and used those switch patterns to lay out my layout. It was fun doing it that way.

Full Size Paper Templates

As for the template's I did download some from the Peco site but the problem I had was The majority of points I am using have been inherited from an old layout that I dismantled

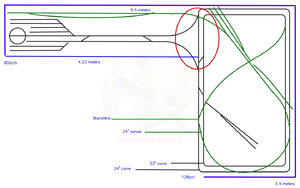

My initial plan was to rebuild using a lot of the same rolling stock carried over from my old layout. My previous layout was based on Australian railways, the locos used are a lot smaller locos than American locos. So the transfer should have been quite simple. I pre-designed a layout to fit the available space and everything was going to plan, But I'm sure you can appreciate that this is a hobby that is only limited buy your imagination, there are endless possibilities. (My mind began to wonder) it has now become an idea that is constantly evolving.

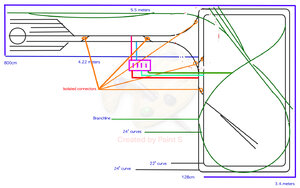

Since my last post I went out to the shed and removed all my curves and converted them to 24" as a result I uncovered a number of points that should suffice as I now know they are Peco #5 curves. Monumental job though. I think this will better in the long run.

Yes, mix the dry ingredients well, then spread them as best you can. It will be lumpy. I used a small glass baby food jar to roll it out smooth, and I forget what else I did to try to make it look 'lived in'.

Then, I sprayed it with 70% alcohol in small patches so the alcohol wouldn't evaporate too soon before I applied a spray of the light glue mixture. Note that the glue solution also has two drops of liquid dish detergent to help break surface tension wherever it is applied. Important. The isopropyl alcohol does a good job at first doing that, but it doesn't penetrate as far as the glue will because it dries so quickly.

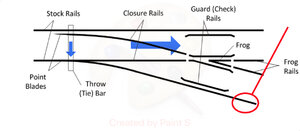

I always, but ALWAYS, draw a scale diagramme first when planning a layout. This initially confirms the concept. Then, I go to the cleared space and lay out the edges of all the benches with 3/4" cheap masking take. Next, start at a measured spot, per the plan, and commence using the same tape to mark out all the curves and tangents. Use a length of lath to fashion a trammel with a small hole every inch and an end-pin for a swivel point for the curves. When it comes to points, USE A REAL TEMPLATE!!!!!!!!!! Beiland suggests this, and it is about as vital as could be. People fool themselves when it comes to figuring where a point is going to go, how long it is if it's commercial, and how much the diverging route actually diverges. If you bugger this up, your entire track system will suffer, and so will your enjoyment.

Thank's for the tips I will definitely try your idea with the plaster when I get to that stage.

When I started planning my layout I took a similar approach. I first made a rough drawing using a basic drawing app. The layout is an L shape design. So I had limited space to design loops. To get the optimum running space I measured the width of the main running area found the centre and used a trammel that I pre-measured and cut and simply drew my curves. I layed my track by simply following the lines. It worked fine until I came to the conclusion that the layout was too restrictive. I originally wanted everything to be within easy reach but it's not going to be possible if I wanted to diversify what I run.

As mentioned above I have since redesigned all my curves to 24". it was a bit of work but I managed to finish the job today. Turned out ok. As for the points. I managed to pull most of them when I was pulling up track so I can rethink how I 0properly plan them out.

I must admit, I'm so glad I sent a post. All the advice I have received has helped me rethink and better plan the rest of my layout. can't thank you all enough.