You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

HO Turn Table from Scratch

- Thread starter KB02

- Start date

KB02

Well-Known Member

Onto the pit...

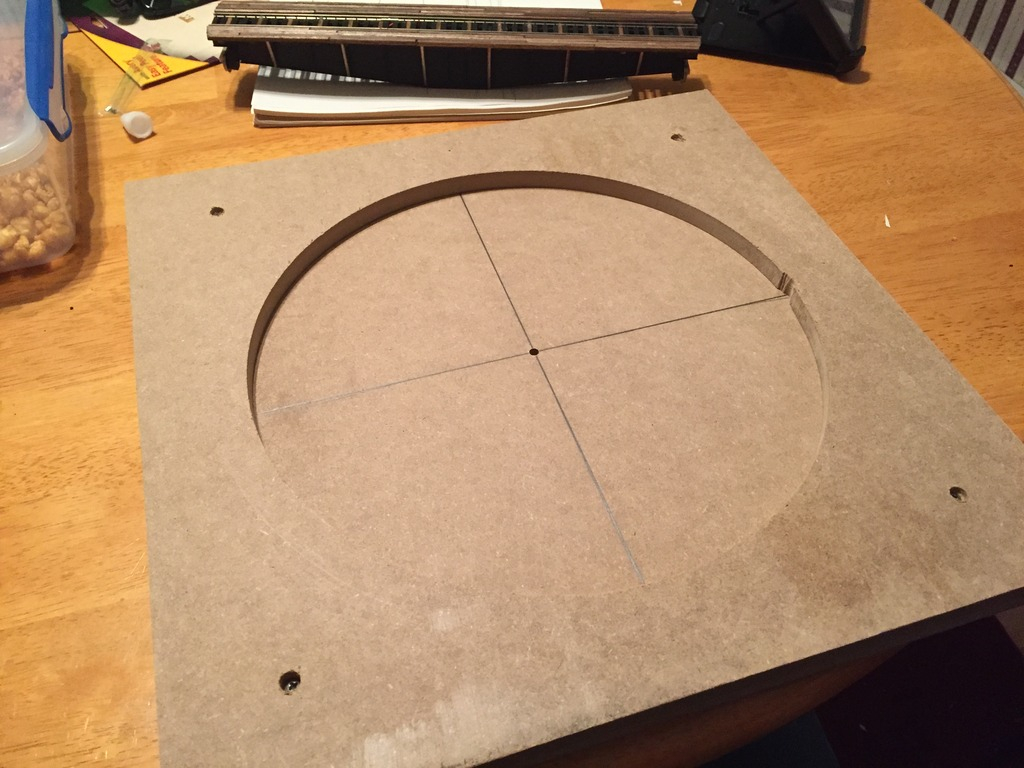

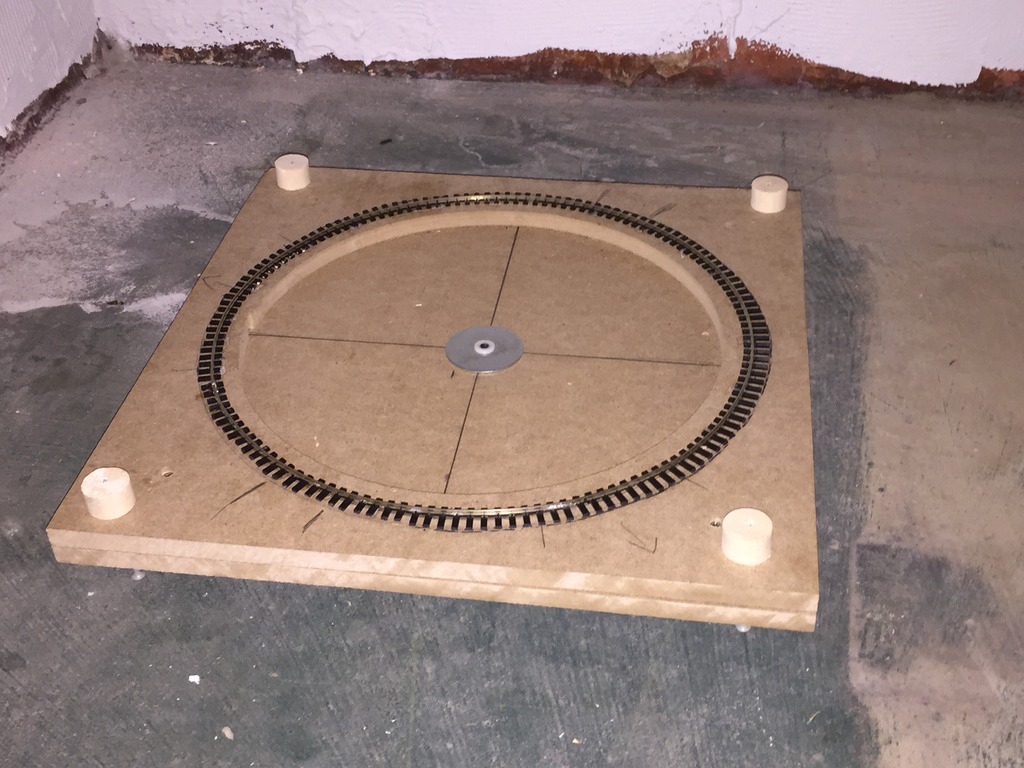

This is still a work in progress, but the main plan is coming together. With the whole cut for the inner pit, I attached a sheet of wood underneath the ring to form the bottom of the pit taking careful measurements to ensure I got the center hole right in the center:

Ended up being off by just a touch, but it will be close enough to work. Only off by a mm or so.

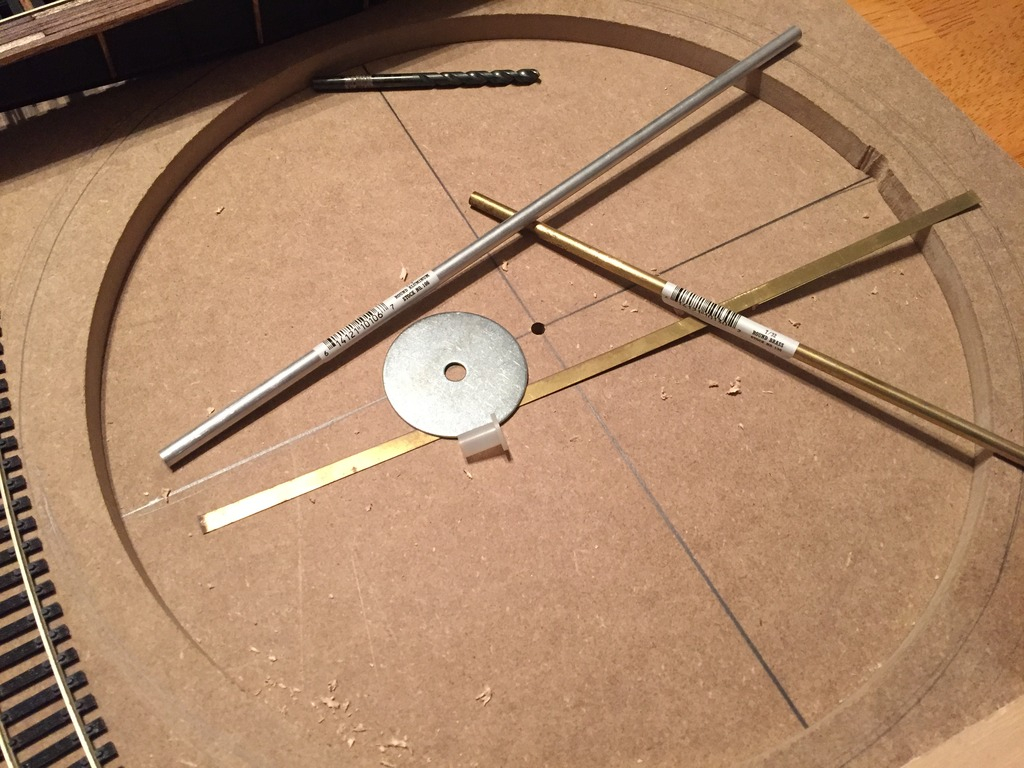

Then a trip to the hardware store and about $5.0 later I had what I needed for the rotation and electricity pass through:

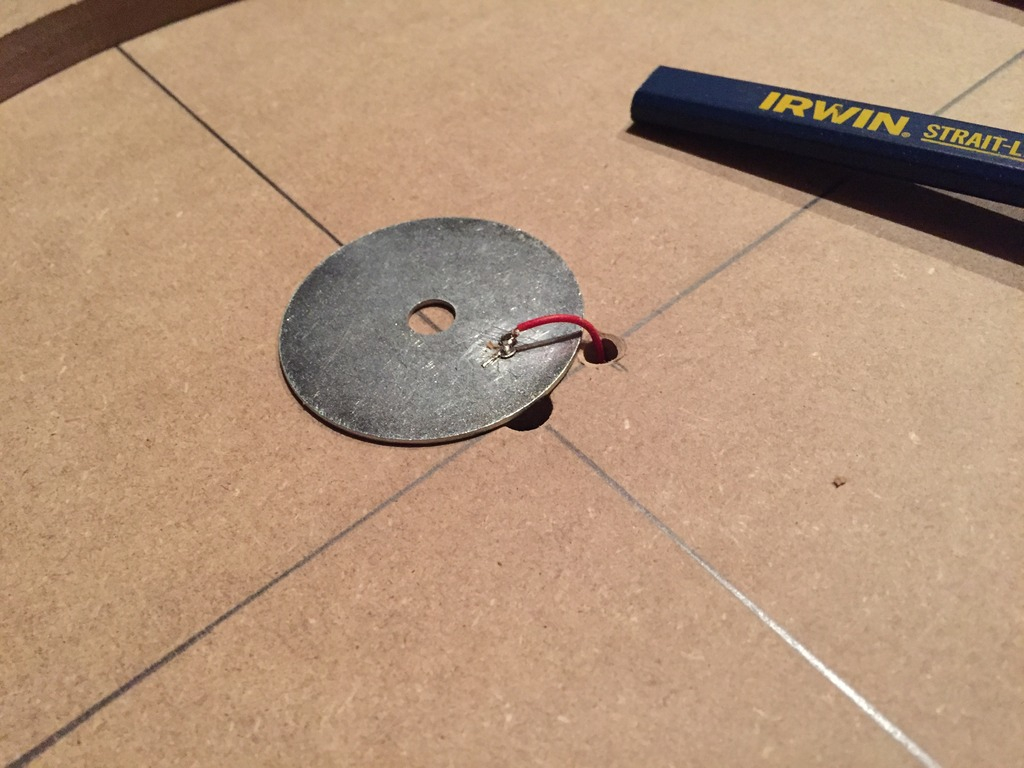

One wire will be soldered to this large flat washer:

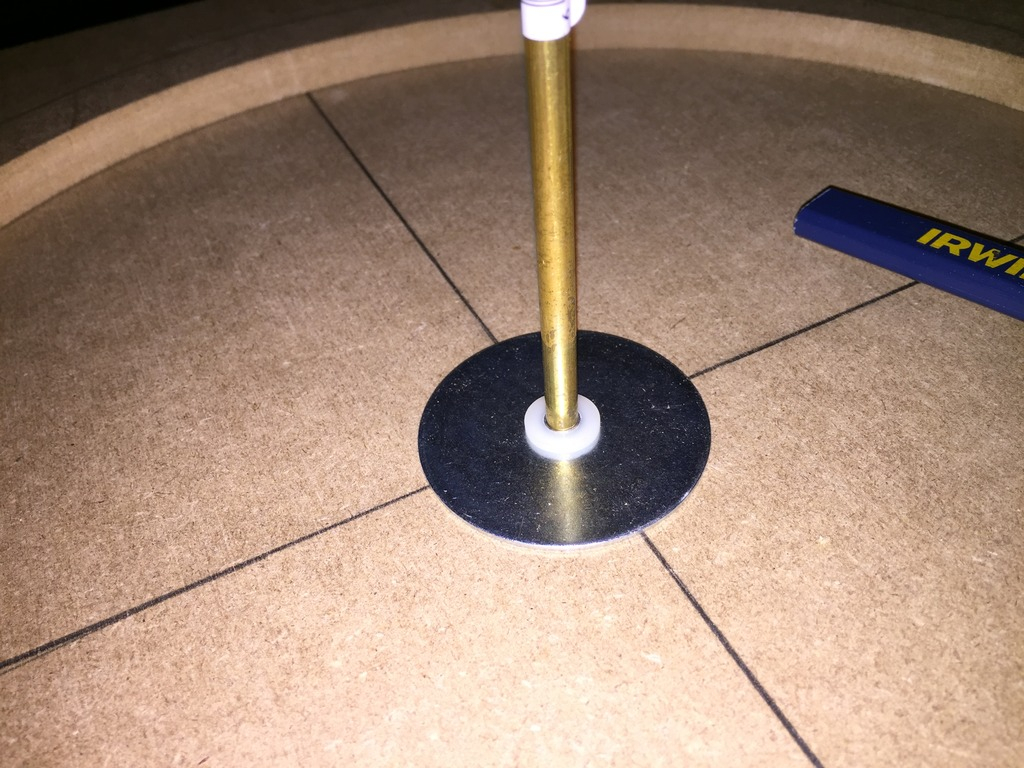

A nylon bushing will hold it in place and separate it electronically from the brass rod that will be coming up through the center which will carry the power to the other rail:

Wire from one track will come down and attach to the brass tube under the bridge. The other wire will attach to a wiper that will be attached to the bridge and slid along the large washer making the connection there. At the bottom of the brass tube will be another wiper attached to the frame that will transfer power to the tube.

And here is the bridge sitting and spinning very nicely on it's pivot:

This is going to be a very deep pit. I'll have to chalk that up to a design flaw. But that bridge should look strong enough to hold a 747 or two.

This is still a work in progress, but the main plan is coming together. With the whole cut for the inner pit, I attached a sheet of wood underneath the ring to form the bottom of the pit taking careful measurements to ensure I got the center hole right in the center:

Ended up being off by just a touch, but it will be close enough to work. Only off by a mm or so.

Then a trip to the hardware store and about $5.0 later I had what I needed for the rotation and electricity pass through:

One wire will be soldered to this large flat washer:

A nylon bushing will hold it in place and separate it electronically from the brass rod that will be coming up through the center which will carry the power to the other rail:

Wire from one track will come down and attach to the brass tube under the bridge. The other wire will attach to a wiper that will be attached to the bridge and slid along the large washer making the connection there. At the bottom of the brass tube will be another wiper attached to the frame that will transfer power to the tube.

And here is the bridge sitting and spinning very nicely on it's pivot:

This is going to be a very deep pit. I'll have to chalk that up to a design flaw. But that bridge should look strong enough to hold a 747 or two.

Ended up being off by just a touch, but it will be close enough to work. Only off by a mm or so.

Ha...ha...finding that EXACT center hole can be a little more challenging than one would think.

Looks like you are doing a really nice job.

Last edited by a moderator:

flyboy2610

Loveably weird

That is looking good so far!

KB02

Well-Known Member

Got a bunch of stuff in the mail yesterday (and today), so it was time to get more work done.

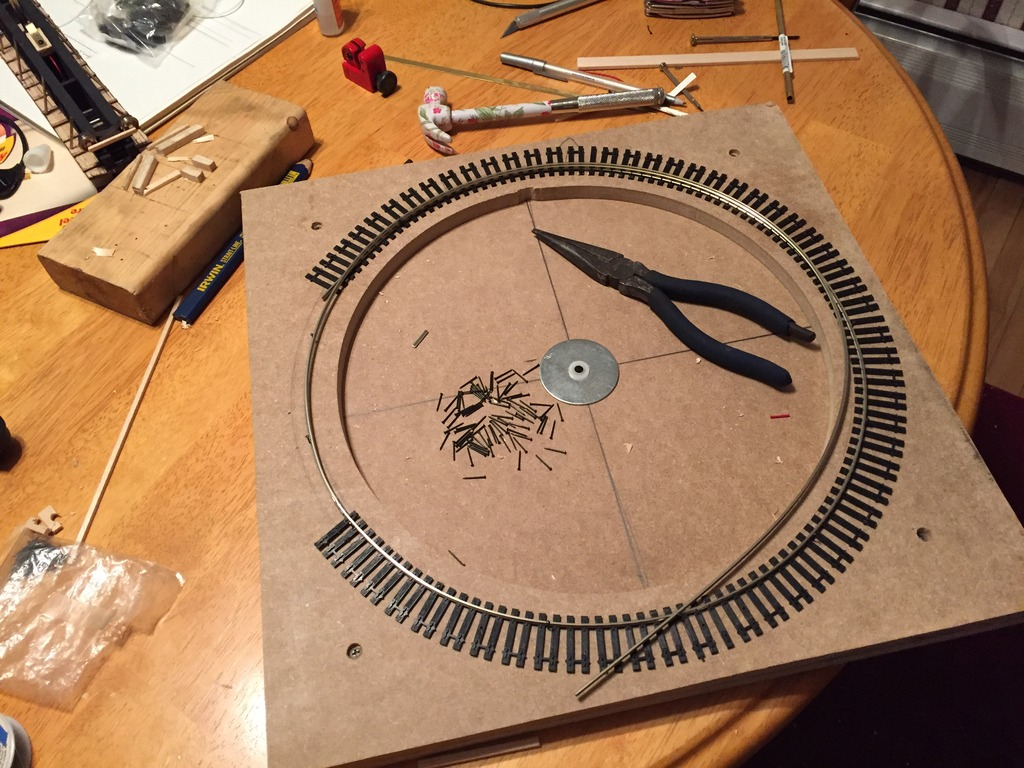

The next step was getting the rail in place. I used a piece of Atlas super-flex track for the rail. Roughly a 44" circumference to the rail. Carefully went around the track with a pencil attached to the bridge marking out where the rail needed to be and marked the line. Then I took track nails and spiked them into place. Next was laying down the track into the nail so that it would stay in place.

I pull one rail right out of the flax track and laid the other in place. I soldered the other rail to the end to give myself one, 6 foot piece of rail that was winding around the loop. I marked the spot on both rails where I wanted it cut and carefully used the Dremmel to cut them. Soldered that connection together as well and went to work cutting the ties in half. Had to use about 1/3 of the ties that were cut to fill in the gap made by the extra rail. Took a little time, but I got it done.

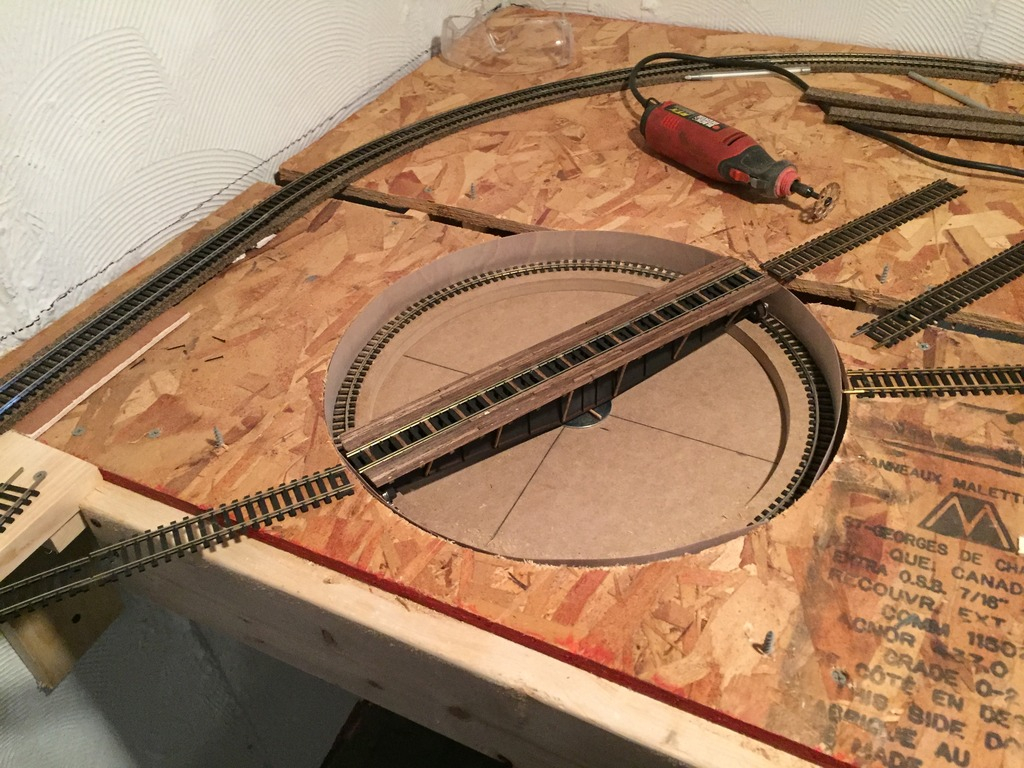

Bridge back in place and turning like a champ!

Well... kinda turning like a champ. It's not as smooth as I had hoped. I do have one tight spot where the track is not as round as I had planned. Seems to still work, though. I might have to reconsider my method of powering it, too. I'm starting to wonder if the motor I had planned to use is going to be strong enough. We'll see. I still have to find a gear that will mesh well with it.

BUT, in the mean time, a #6 turnout arrived in the mail today and my AR1 auto reverser came yesterday with the flex track. Looks like this will be a go to get this all installed and ready to test.

The next step was getting the rail in place. I used a piece of Atlas super-flex track for the rail. Roughly a 44" circumference to the rail. Carefully went around the track with a pencil attached to the bridge marking out where the rail needed to be and marked the line. Then I took track nails and spiked them into place. Next was laying down the track into the nail so that it would stay in place.

I pull one rail right out of the flax track and laid the other in place. I soldered the other rail to the end to give myself one, 6 foot piece of rail that was winding around the loop. I marked the spot on both rails where I wanted it cut and carefully used the Dremmel to cut them. Soldered that connection together as well and went to work cutting the ties in half. Had to use about 1/3 of the ties that were cut to fill in the gap made by the extra rail. Took a little time, but I got it done.

Bridge back in place and turning like a champ!

Well... kinda turning like a champ. It's not as smooth as I had hoped. I do have one tight spot where the track is not as round as I had planned. Seems to still work, though. I might have to reconsider my method of powering it, too. I'm starting to wonder if the motor I had planned to use is going to be strong enough. We'll see. I still have to find a gear that will mesh well with it.

BUT, in the mean time, a #6 turnout arrived in the mail today and my AR1 auto reverser came yesterday with the flex track. Looks like this will be a go to get this all installed and ready to test.

montanan

Whiskey Merchant

KB02

Well-Known Member

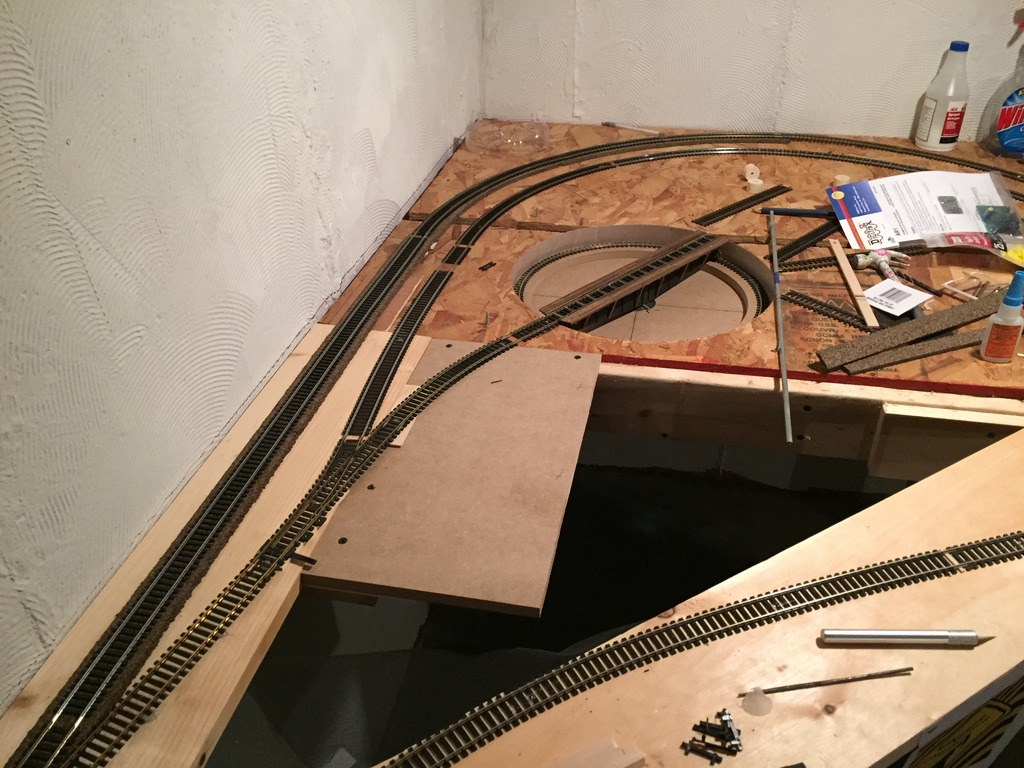

Okay. Got back at it over the weekend and got it installed in it's temporary location. (I am doing an awful lot in this temporary location, too...)

As the track comes down from the left of the picture, this will eventually just be a turn to the right and go along that wall. Right now, it is just a temp structure to turn trains around and send them back up the hill. BUT, it will work as a place to be a service yard for now.

Put spacers on the top of the platform and then screwed it to the under side of the table.

The first spacers turned out to be off by about 1/8", so I cut new ones and re-did the process. Then I drilled a hole in the table top through the center hole in the pit. This way I have a good "Center" with which to bring in my large hole jig. After removing the pit platform, I cut the big hole.

I went back to the veneer and cut out sides for the pit and glued them into place (after the picture was taken):

Then I laid some and replaced some track to bring a train to and around it:

I have some time off from work coming up, so I will be getting it wired in shortly (probably this weekend some time). My first attempt to run a train onto it (because am impatient0 was moderately successful. I had forgotten to file the edges of the rails to ease the transition, and the loco I ran onto it uses a keep alive, so it derailed halfway across and tried to run off the other side. Oh well. I'll get that fixed.

Once the wiring is done, I will have to turn to motorization. Where is a good source to look at gears?

As the track comes down from the left of the picture, this will eventually just be a turn to the right and go along that wall. Right now, it is just a temp structure to turn trains around and send them back up the hill. BUT, it will work as a place to be a service yard for now.

Put spacers on the top of the platform and then screwed it to the under side of the table.

The first spacers turned out to be off by about 1/8", so I cut new ones and re-did the process. Then I drilled a hole in the table top through the center hole in the pit. This way I have a good "Center" with which to bring in my large hole jig. After removing the pit platform, I cut the big hole.

I went back to the veneer and cut out sides for the pit and glued them into place (after the picture was taken):

Then I laid some and replaced some track to bring a train to and around it:

I have some time off from work coming up, so I will be getting it wired in shortly (probably this weekend some time). My first attempt to run a train onto it (because am impatient0 was moderately successful. I had forgotten to file the edges of the rails to ease the transition, and the loco I ran onto it uses a keep alive, so it derailed halfway across and tried to run off the other side. Oh well. I'll get that fixed.

Once the wiring is done, I will have to turn to motorization. Where is a good source to look at gears?

KB02

Well-Known Member

Took the day and got some electrical work done. Got the lower power wiper and the auto reverser installed (bad picture, I know...):

Then I finished laying the track and the parking tracks and got it all wired up. Took a bit, but I got the job done. Then it was testing time. Mostly successful. I have found that the bogie wheels on the bridge were not completely level. Not too far off, but off enough to cause some glitches. I can work with it, though.

The Auto reverser works just fine. The Prodigy express system, though, sees short right away and goes into "savd" mode. It does the same thing whenever the steamer crossed most of my turnouts, too. It's a low voltage system and REALLY picks up ANY short and tries to not work. Really quite annoying. Doesn't shut down the trains, just the cab. From what I have read, I can send the base unit back to MRC and they can actually upgrade it to a higher voltage that will not trip with every little tinny tiny short. Or I just get a booster and run the system off of that. Either way - future plans... BUT, I have been using JMRI and that doesn't shut down, and neither does the WiThrottle. So I'll just keep using that for now.

Anyway, Trains sitting at the ready:

Next step, which will probably take a while, will be motorization.

All tolled, I'm up to about $80.00 so far including the auto-reverser.

Then I finished laying the track and the parking tracks and got it all wired up. Took a bit, but I got the job done. Then it was testing time. Mostly successful. I have found that the bogie wheels on the bridge were not completely level. Not too far off, but off enough to cause some glitches. I can work with it, though.

The Auto reverser works just fine. The Prodigy express system, though, sees short right away and goes into "savd" mode. It does the same thing whenever the steamer crossed most of my turnouts, too. It's a low voltage system and REALLY picks up ANY short and tries to not work. Really quite annoying. Doesn't shut down the trains, just the cab. From what I have read, I can send the base unit back to MRC and they can actually upgrade it to a higher voltage that will not trip with every little tinny tiny short. Or I just get a booster and run the system off of that. Either way - future plans... BUT, I have been using JMRI and that doesn't shut down, and neither does the WiThrottle. So I'll just keep using that for now.

Anyway, Trains sitting at the ready:

Next step, which will probably take a while, will be motorization.

All tolled, I'm up to about $80.00 so far including the auto-reverser.

For motorizing it I'd suggest using ArduinoCMRI and a stepper motor. I'm working on a similar project using an Atlas turntable and a hall effect sensor as a makeshift tachometer, so if you (or anyone else) are into programming I'd love some help.Took the day and got some electrical work done. Got the lower power wiper and the auto reverser installed (bad picture, I know...):

Then I finished laying the track and the parking tracks and got it all wired up. Took a bit, but I got the job done. Then it was testing time. Mostly successful. I have found that the bogie wheels on the bridge were not completely level. Not too far off, but off enough to cause some glitches. I can work with it, though.

The Auto reverser works just fine. The Prodigy express system, though, sees short right away and goes into "savd" mode. It does the same thing whenever the steamer crossed most of my turnouts, too. It's a low voltage system and REALLY picks up ANY short and tries to not work. Really quite annoying. Doesn't shut down the trains, just the cab. From what I have read, I can send the base unit back to MRC and they can actually upgrade it to a higher voltage that will not trip with every little tinny tiny short. Or I just get a booster and run the system off of that. Either way - future plans... BUT, I have been using JMRI and that doesn't shut down, and neither does the WiThrottle. So I'll just keep using that for now.

Anyway, Trains sitting at the ready:

Next step, which will probably take a while, will be motorization.

All tolled, I'm up to about $80.00 so far including the auto-reverser.

I think I recall a few companies making plug-and-play turntable controllers with indexing though, if you're not super thrilled with the idea of programming your own.

KB02

Well-Known Member

Well, I found a motor/gearbox on e-bay that I think will work, so I placed an order for that and now have to wait for abut to 2 weeks for it to get here.  12v motor, so I should be able to place a decoder on it to control it from my DCC system. And at only 10 RPM, I should be able to run it slow enough to place it exactly where I want it. I don't know that I'll be doing any computerized indexing. That may be a bit above my skill level. I'll have to do it the old fashioned way for now. But first it has to get here... I am not patient. Waiting stinks.

12v motor, so I should be able to place a decoder on it to control it from my DCC system. And at only 10 RPM, I should be able to run it slow enough to place it exactly where I want it. I don't know that I'll be doing any computerized indexing. That may be a bit above my skill level. I'll have to do it the old fashioned way for now. But first it has to get here... I am not patient. Waiting stinks.

SO, in the meantime, I started working on decoration.

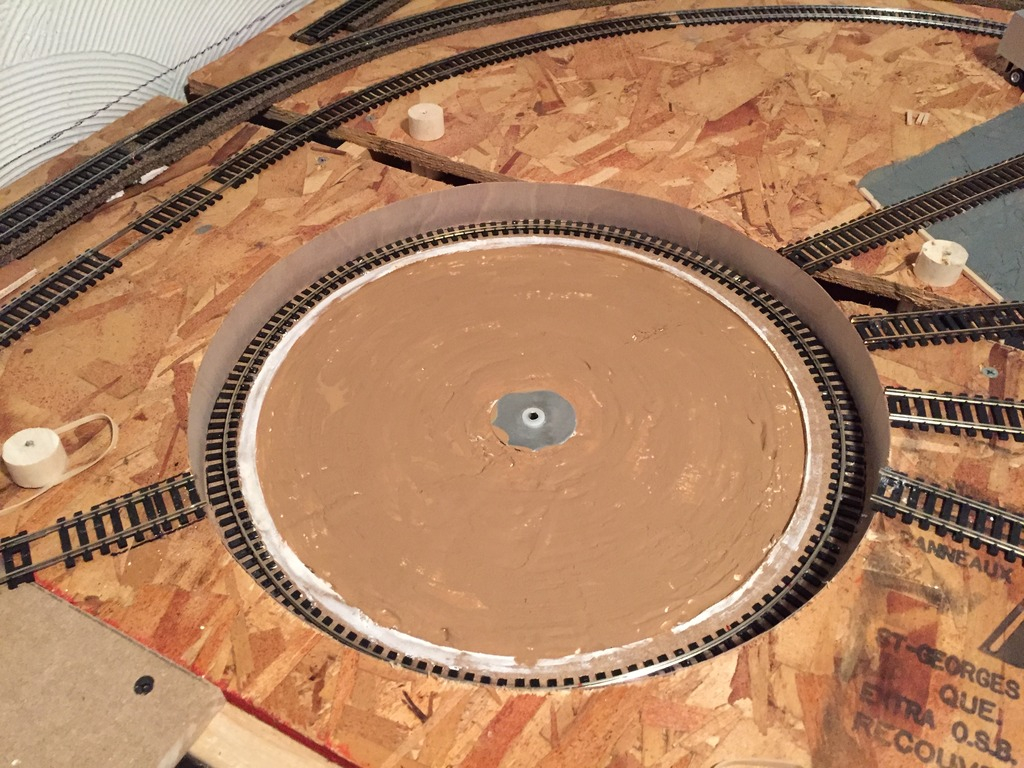

I took some plaster and created the slope in the bottom of the pit. Then I started painting a bit to get it ready for ground cover:

I also painted the riser for rail and the wall, added ballast on the rail and sand in the pit:

And the bridge back in place:

You can also see a corner where I painted the simple outline of a round house on the table. I have to be careful and keep reminding myself that entire structure this is sitting on is only a temporary structure and the turntable will eventually be on the complete opposite corner of the room. But it is going to be a while before I get it there, so I really tempted to just start building structure and lay ground cover all over the place.... very tempting...

I also added a forth "dead" rail in the "roundhouse" just to place a cheap DC loco that came with one of my eBay wins. Just helps fill it up a bit more.

SO, in the meantime, I started working on decoration.

I took some plaster and created the slope in the bottom of the pit. Then I started painting a bit to get it ready for ground cover:

I also painted the riser for rail and the wall, added ballast on the rail and sand in the pit:

And the bridge back in place:

You can also see a corner where I painted the simple outline of a round house on the table. I have to be careful and keep reminding myself that entire structure this is sitting on is only a temporary structure and the turntable will eventually be on the complete opposite corner of the room. But it is going to be a while before I get it there, so I really tempted to just start building structure and lay ground cover all over the place.... very tempting...

I also added a forth "dead" rail in the "roundhouse" just to place a cheap DC loco that came with one of my eBay wins. Just helps fill it up a bit more.

KB02

Well-Known Member

Shot a quick video of the turntable "In-Action." So to speak... Right now it is just a waiting game until the motor gets here. Then we'll see if my plan is going to work or not. I'm not super happy with the way it is turning. I am thinking of ways to alter the design to make it work better. We'll see...

[video=youtube;T_0mPJd5hWc]http://www.youtube.com/watch?v=T_0mPJd5hWc[/video]

[video=youtube;T_0mPJd5hWc]http://www.youtube.com/watch?v=T_0mPJd5hWc[/video]