You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

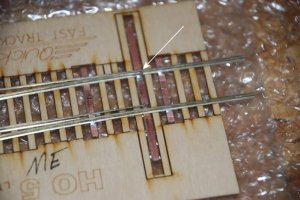

Fast Tracks turn out problems

- Thread starter rzw0wr

- Start date

Trussrod

Well-Known Member

Say Dale,

Like Carey, I've been building my own turnouts for a long time now without using any jigs or any kind. I'm 67 going on 68 yrs [12-15-2013] and I do need to use glasses, I just buy inexpensive Dollar store ones that focus a bit close than for reading as they help in building the turnouts as well as hand spiking my rail. Do my turnouts all look as perfect as jig made ones, no but they do work fine for me after a bit of tweaking sometimes.

In your picture I'm wondering why it shows both point rails touching the stock rails at the same time? I'm assuming you haven't connected them to the throw bar or tie depending on what your using?

Also you mention about the rails buckeling and that would tend to indicate you haven't fround off enough of the bottom web on the Stock rail/s or also on the Point rails so they can mesh together with two flat or near flat surfaces matting. I use a dremel tool with a cut-off wheel to grind my rails and just work free hand and try and allow for enough taper so the rail bottom web's don't come in contact but I've had to use the Cut-off wheel to take a little more off here and there.

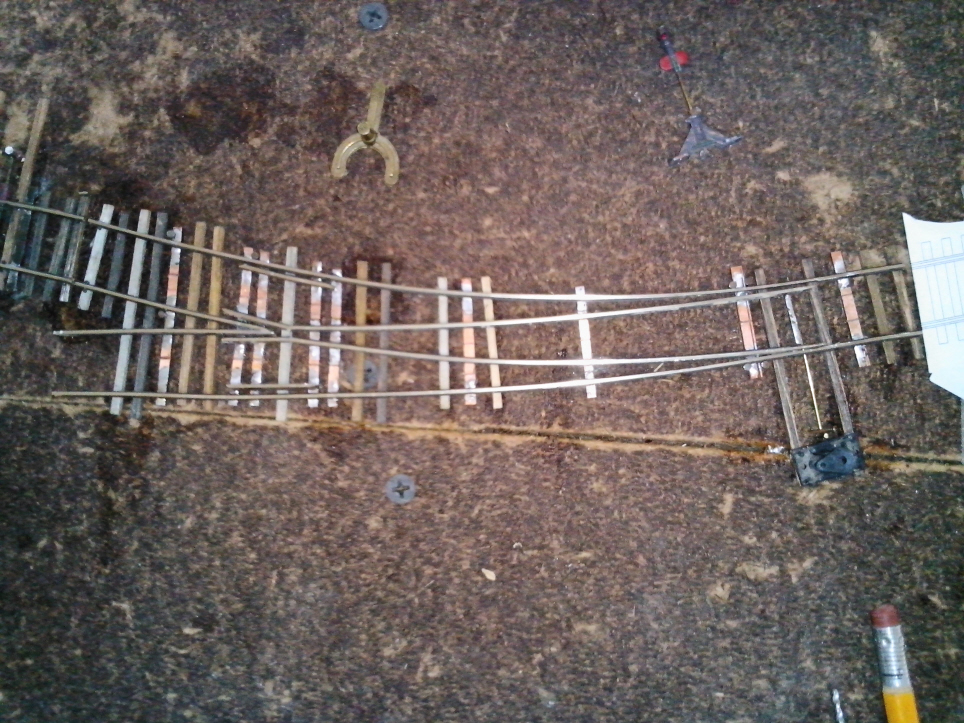

Here's a #6 Right hand curved one I did a while back. I'm still running just 'DC' also.

You might note that I also use a metal throw bar soldered to the points and with extra gaping everything is works fine with no shorts but I should mention that I don't use any rail joiners at all and the turnouts are stand alone and powered as hot all the time.

Also note that I use double PC tie strips at the frog and prior to it to give extra strength in that area as my points are and frog are basically all interconnected.

Hope this helps to show you what can be done without any jigs but some good three point track gauges like Mirco Engineerings or others are needed.

Like Carey, I've been building my own turnouts for a long time now without using any jigs or any kind. I'm 67 going on 68 yrs [12-15-2013] and I do need to use glasses, I just buy inexpensive Dollar store ones that focus a bit close than for reading as they help in building the turnouts as well as hand spiking my rail. Do my turnouts all look as perfect as jig made ones, no but they do work fine for me after a bit of tweaking sometimes.

In your picture I'm wondering why it shows both point rails touching the stock rails at the same time? I'm assuming you haven't connected them to the throw bar or tie depending on what your using?

Also you mention about the rails buckeling and that would tend to indicate you haven't fround off enough of the bottom web on the Stock rail/s or also on the Point rails so they can mesh together with two flat or near flat surfaces matting. I use a dremel tool with a cut-off wheel to grind my rails and just work free hand and try and allow for enough taper so the rail bottom web's don't come in contact but I've had to use the Cut-off wheel to take a little more off here and there.

Here's a #6 Right hand curved one I did a while back. I'm still running just 'DC' also.

You might note that I also use a metal throw bar soldered to the points and with extra gaping everything is works fine with no shorts but I should mention that I don't use any rail joiners at all and the turnouts are stand alone and powered as hot all the time.

Also note that I use double PC tie strips at the frog and prior to it to give extra strength in that area as my points are and frog are basically all interconnected.

Hope this helps to show you what can be done without any jigs but some good three point track gauges like Mirco Engineerings or others are needed.

you must file the points back further, from the outside and inside. Otherwise you end up with "narrow gauge". Listen to us, I've done my own track laying. The prototype non point rails are usually standard rails, the points just lay into the rail, but for us modelrs it helps if you file out the rail where the points meet. To help with point movement cut the point rails about halfway between point and from and insert rail joiners. longer turnouts can be closer to the points. I never used fast tracks and have built slip switches.

cncproadwarrior

North of the 49th

Examine Bernie's photo and note how thin and long the point's taper is compared to the OP's photo in the first post.

The point rails do need that taper and filed way back further than you think. Also, ensure that enough relief is filed into the stock rails for the point rails to set closed.

These were the two issue I had on the first few turn-outs I hand built. Once you become aware of these then the next turn-out works out better.

The point rails do need that taper and filed way back further than you think. Also, ensure that enough relief is filed into the stock rails for the point rails to set closed.

These were the two issue I had on the first few turn-outs I hand built. Once you become aware of these then the next turn-out works out better.

My stock rail filing jig came today.

I would appear that I was not filing the stock rail properly.

The point rails now lay very closely with very little gap.

I figured that it was something I was doing wrong and it was.

Now all I need to do is to go back and try to fix 5 turnouts that are not correct.

Thanks for the replies.

I would appear that I was not filing the stock rail properly.

The point rails now lay very closely with very little gap.

I figured that it was something I was doing wrong and it was.

Now all I need to do is to go back and try to fix 5 turnouts that are not correct.

Thanks for the replies.