You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cutting Foam

- Thread starter brubakes

- Start date

ModelRailroadForums.com is a free Model Railroad Discussion Forum and photo gallery. We cover all scales and sizes of model railroads. Online since 2002, it's one of the oldest and largest model railroad forums on the web. Whether you're a master model railroader or just getting started, you'll find something of interest here.

Jeff,

Sorry for taking so long to respond. The hot knife is a Weller TB 100 that I purchased as Lowe's. The canal should have never have been 2" deep. I ended up having to fill much of the cut out area to get it up to about 3/4" in depth.

Larry

Affiliate Disclosure: We may receive a commision from some of the links and ads shown on this website (Learn More Here)

hamltnblue

Active Member

I used a sharp 2 inch exacto razer.

Littlefoot14

Active Member

i use an exacto knife, and its sharp!

however if youll be doing alot of cutting foam, there are heated wires and heated knife things that cut with much more ease

however if youll be doing alot of cutting foam, there are heated wires and heated knife things that cut with much more ease

Beachbum

Member

Bread knives, steak knives, hot wire cutters (beware as the fumes are toxic, or so they say), wire brushes, rotating wire brushes (clamp 'em in the chuck of your drill - I use a hand crank drill since an electric drill flings foam everywhere), Surform planes, coarse grit sandpaper, utility knives...

You can use virtually anything you can think of to cut and shape foam. The main issues are fumes if you melt the stuff and little bits of static-cling foam - on the wall, on your clothes, on the carpet, on the dog...

You can use virtually anything you can think of to cut and shape foam. The main issues are fumes if you melt the stuff and little bits of static-cling foam - on the wall, on your clothes, on the carpet, on the dog...

I used most of the previously mentioned tools. I also used an electric carving knife, it worked quite well but got a bit hot on long runs. Had to but a new one for Thanks Giving.

Against advice from many on this sight, I used white foam, because that's all that was available at the time, it didn't create too much of a hassle as long as I kept my dust buster close at hand and fully charged.

Good luck.

Mac

Against advice from many on this sight, I used white foam, because that's all that was available at the time, it didn't create too much of a hassle as long as I kept my dust buster close at hand and fully charged.

Good luck.

Mac

Beachbum

Member

I think that depends on what he's trying to do - straight cut, curve, contours, texture, "ditches", etc. Maybe I misunderstood the OP.

Thought of one more - a drywall saw. I have one that has a tapered 6-in long blade on a wooden handle with coarse teeth. They're used for cut outs for junction boxes, etc.

You might want to try different things on some foam scraps so you can see the difference in cuts, textures, etc.

Thought of one more - a drywall saw. I have one that has a tapered 6-in long blade on a wooden handle with coarse teeth. They're used for cut outs for junction boxes, etc.

You might want to try different things on some foam scraps so you can see the difference in cuts, textures, etc.

Last edited by a moderator:

I used a jigsaw, a kitchen knife (still hearing it about that one), and i used a wire cutter. the wire cutter worked really well but things always seemed a little floaty after an hour of cutting. Guess I shoulda ventilated better.

I thought the wire cutter was good but the wire kept breaking. Next time I have to do a lot of foam cutting I think i will get one of the heated knives for the purpose just because it wouldn't break so often.

I thought the wire cutter was good but the wire kept breaking. Next time I have to do a lot of foam cutting I think i will get one of the heated knives for the purpose just because it wouldn't break so often.

jdetray

Well-Known Member

A serrated steak knife or bread knife works well on foam -- much better than an Xacto knife or utility knife when you are working on 2-inch foam.

For making foam risers from 2-inch foam, I first use a table saw to cut long pieces of foam that are a little wider than my roadbed. Then I use a miter saw to cut the long pieces into individual risers. I set the angle on the miter saw to match the grade I'm working on at the time.

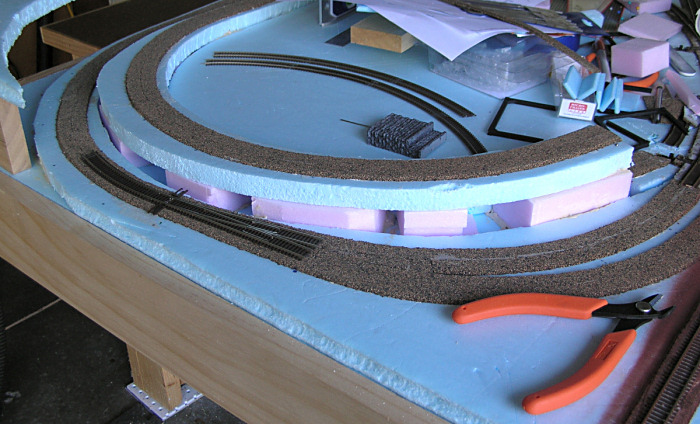

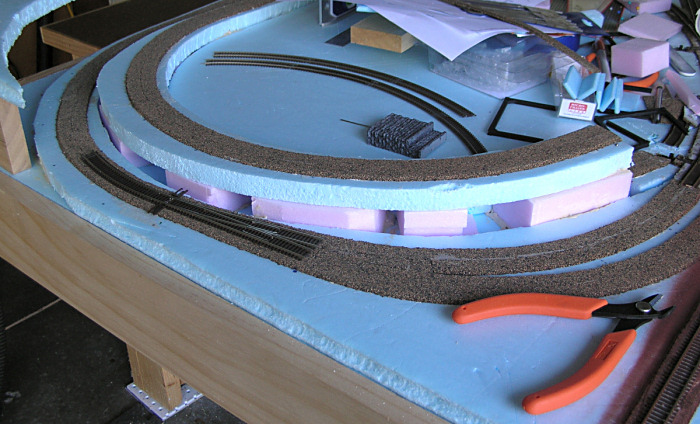

The pink chunks of foam in the picture below are the risers I'm talking about.

- Jeff

For making foam risers from 2-inch foam, I first use a table saw to cut long pieces of foam that are a little wider than my roadbed. Then I use a miter saw to cut the long pieces into individual risers. I set the angle on the miter saw to match the grade I'm working on at the time.

The pink chunks of foam in the picture below are the risers I'm talking about.

- Jeff

railBuilderDhd

Active Member

Larry, that is cool but be sure you have the windows open when you do the cutting.

Dave

Dave

Beachbum

Member

Almost looks like a king hell woodburning pen. I'll have to see what my local Lowes / HD / Menards have...

That reminds me - somebody somewhere wrote that they took a cheap Radio Shack soldering gun, removed the heating element, and replaced it with a loop of solid copper wire that they beat down with a hammer into a U-shaped flat cutting tool, the flat part being at the bottom of the U.

Ditto on the fumes warning.

That reminds me - somebody somewhere wrote that they took a cheap Radio Shack soldering gun, removed the heating element, and replaced it with a loop of solid copper wire that they beat down with a hammer into a U-shaped flat cutting tool, the flat part being at the bottom of the U.

Ditto on the fumes warning.

Last edited by a moderator:

railBuilderDhd

Active Member

Yes, a good shop vac. I can't believe it's not been mentioned till now. I do as much cutting outside as I can and that helps keep the mess out of everything in the house. It's not too bad since I'm only working on modules and not a built-in layout.

Dave

Dave

68 Camaro

Member

Larry -

That is a neat tool. What is it called, and what department did you find it in? I can't quite read the label.

- Jeff

Jeff,

Sorry for taking so long to respond. The hot knife is a Weller TB 100 that I purchased as Lowe's. The canal should have never have been 2" deep. I ended up having to fill much of the cut out area to get it up to about 3/4" in depth.

Larry

Affiliate Disclosure: We may receive a commision from some of the links and ads shown on this website (Learn More Here)