a few seconds ago

Bachmann 4-8-4 Northern (HO) derails,...engine or track initiated?

I have 3 of the Santa Fe versions of these engines, and they all have the long-haul tenders. And to my knowledge they are all the latest versions of these locos, even thought they are no longer marketed. I'm betting they will all look super after a decent weathering job.

I have experienced a particular problem recently while running one of them around the lower level of my layout,...a tender that derails its front truck,...not always but often enough to really bug me. And it all occurs at a particular spot. It has me wondering if its a problem with the track in that spot, or the loco in that spot??

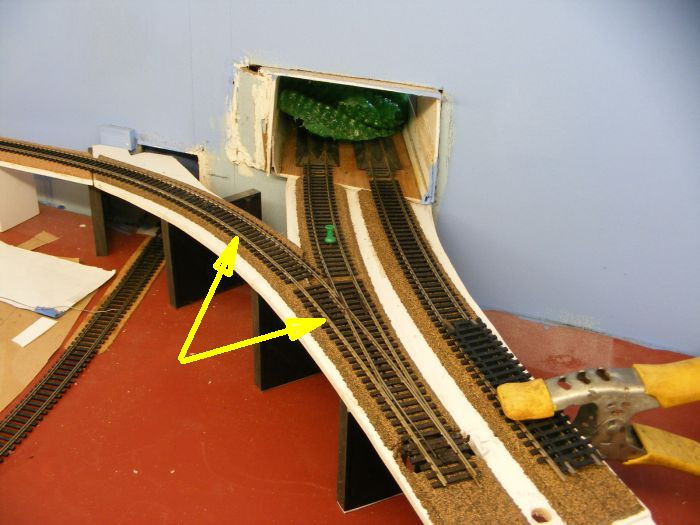

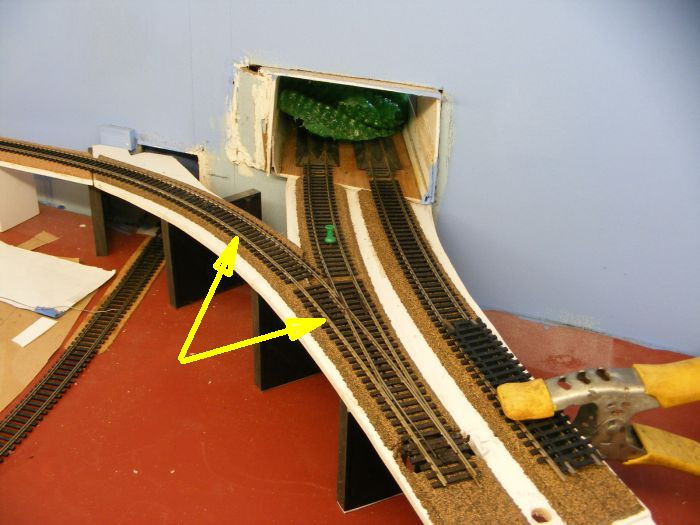

The loco comes up the viaduct incline, then is directed off to the left by a large radius Peco 'Y' to proceed down the other incline of the viaduct.

Up until recently all of the locos and trains I've run across this Y turnout and around the that bottom loop of my layout have run fine,...even the Bachmann Northern. But most recently I had detected a little clicking noise as the loco passed thru this spot. Then I began to experience a lot of derails by the front truck of that long-haul tender.

I need to determine what is the problem,...is it the track work OR the loco??

Bachmann 4-8-4 Northern (HO) derails,...engine or track initiated?

I have 3 of the Santa Fe versions of these engines, and they all have the long-haul tenders. And to my knowledge they are all the latest versions of these locos, even thought they are no longer marketed. I'm betting they will all look super after a decent weathering job.

I have experienced a particular problem recently while running one of them around the lower level of my layout,...a tender that derails its front truck,...not always but often enough to really bug me. And it all occurs at a particular spot. It has me wondering if its a problem with the track in that spot, or the loco in that spot??

The loco comes up the viaduct incline, then is directed off to the left by a large radius Peco 'Y' to proceed down the other incline of the viaduct.

Up until recently all of the locos and trains I've run across this Y turnout and around the that bottom loop of my layout have run fine,...even the Bachmann Northern. But most recently I had detected a little clicking noise as the loco passed thru this spot. Then I began to experience a lot of derails by the front truck of that long-haul tender.

I need to determine what is the problem,...is it the track work OR the loco??