homersimpsonlikestrains

Active Member

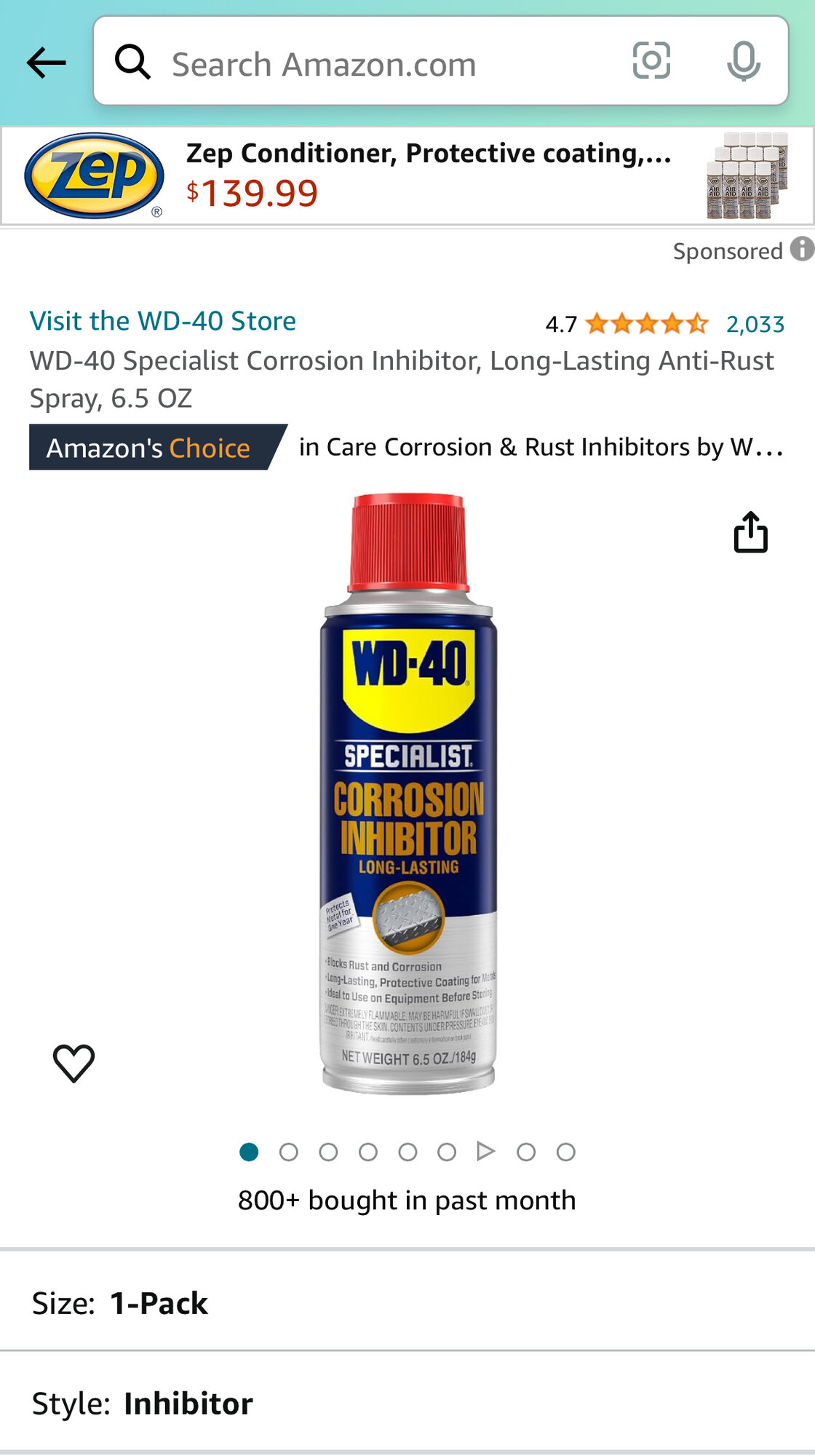

Will this specific WD-40 prevent rust from building up again on Lionel tubular track? I am asking this because I dipped my used and rusty tubular track in vinegar for 24 hours and the rust was removed. Unfortunately the rust came back when I air dried them.

Last edited: