Habbyguy

Member

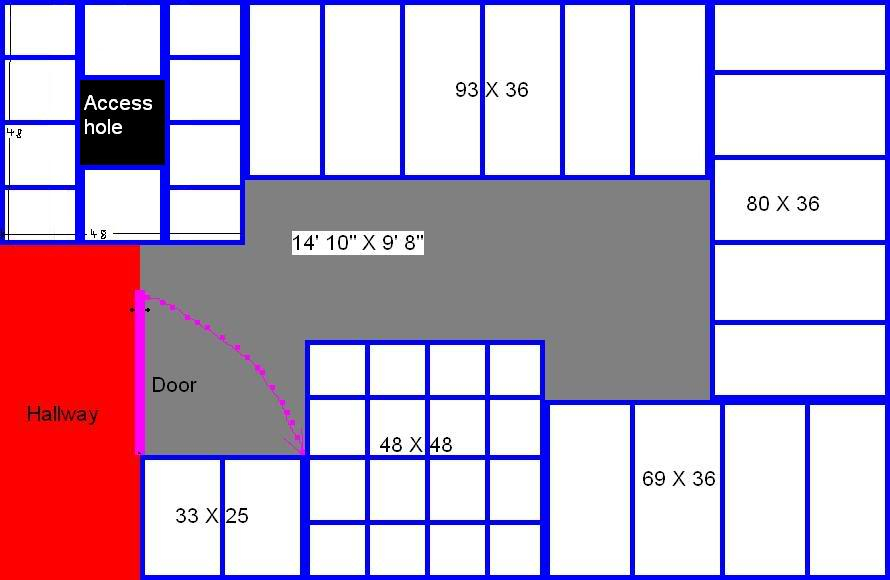

I would like to have at least 2 loops, maybe 3 loops(if possible). I am DCC ready with a MRC Command 2000 with some hand-held controllers that I have had for years. But right now I just need to figure the best use of space in my empty room. All ideas are welcome.

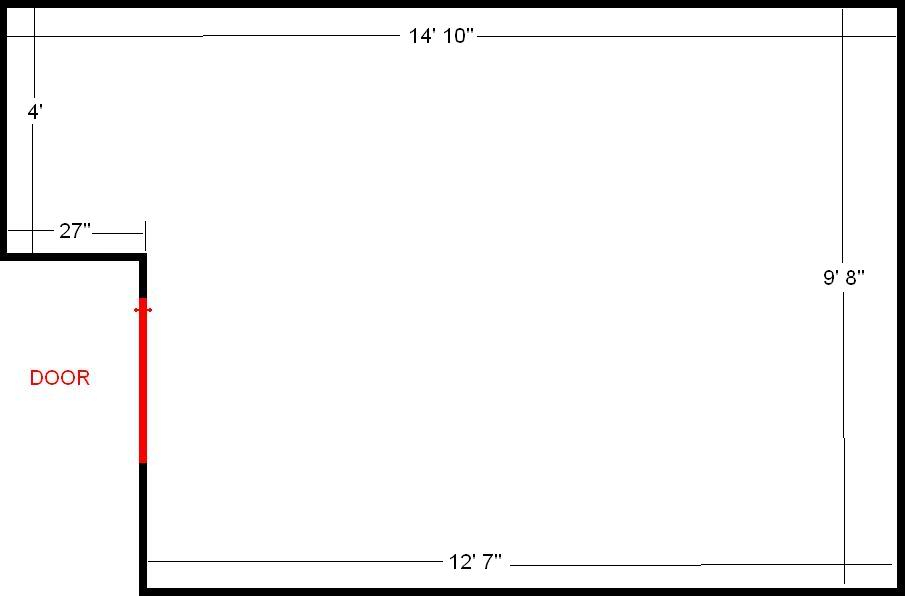

The room is 12' 7" X 9' 8", plus closet that is 2' 3" X 4'.

And I was thinking of something like this.

The room is 12' 7" X 9' 8", plus closet that is 2' 3" X 4'.

And I was thinking of something like this.