Jim, Very nice modeling and outstanding trackwork! Such an ambitious project! My wife and I visited your country years ago and rode all around using a BritRail Pass. I even rode the Severn Valley. Wonderful good fun and friendly people, such as yourself. Thanks for sharing your techniques with us on this side of the pond. Keep the photos and ideas coming.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Under Construction - Birmingham UK

- Thread starter jim smith-wright

- Start date

ModelRailroadForums.com is a free Model Railroad Discussion Forum and photo gallery. We cover all scales and sizes of model railroads. Online since 2002, it's one of the oldest and largest model railroad forums on the web. Whether you're a master model railroader or just getting started, you'll find something of interest here.

Hiya

The base is foamboard with the plastic stuck to it. I use self aadhesive foamboard or double sided tape to laminate the materials together, this stops it warping as solvents dry.

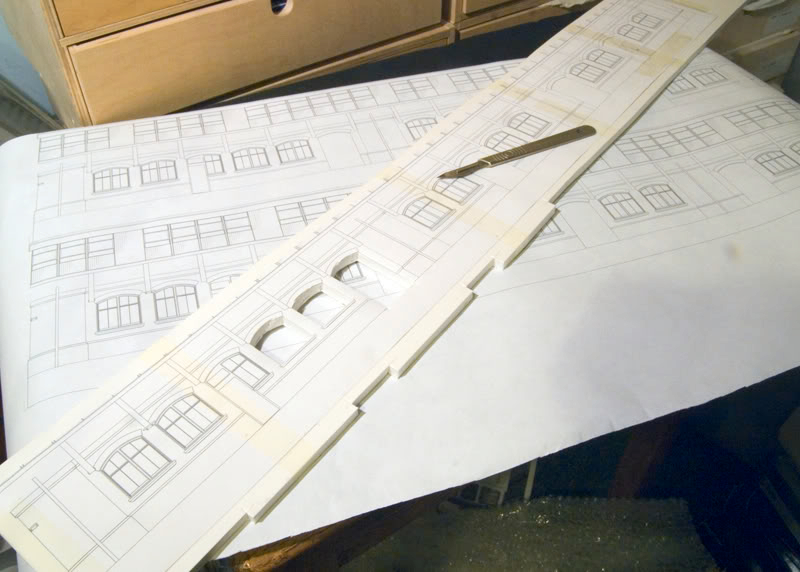

The pic shows the marking out stage. I draw everything in Adobe Illustrator first and print it out. This is then taped to the foamboard and cut through. It does destroy the drawing thats why I have the spares in the picture.

This method saves all the marking out and the potential risk of errors an extra stage can bring. You should be able to use your metcalf building in the same way, perhaps covering the faces in plasticard and cutting out the windows from the back?

HTH

Jim

Hi

All the OLE is scratchbuilt. The insulators are the only thing off the shelf (from sommerfeldt) and they are the weakest part. Luckily one of my friends has produced a small range of British insulators.

The contact wire is 10thou steel and is (I am told) used in the machine industry for cutting steel plates. Apparently the machines they use need miles of the stuff and big reels of it are thrown away. It is tensioned with springs in the bridges.

HTH

Jim

You are more than welcome. Thanks for the kind words.

The Severn Valley is within 25 miles of my house and about 5 miles from my fiancée's home. I have been on it several times but as is so often the case when something is right there I dont go on it enough. A large part of it has been closed for a year or so as heavy rains in 2007 washed some of it away. Due to the hard work of the volenteers and the donations of the public its all repaired now.

Regards

Jim

Hi Steve

Like Spray mount? I didnt have any handy at the time but I would use it if I had it!

Regards

Jim

Affiliate Disclosure: We may receive a commision from some of the links and ads shown on this website (Learn More Here)

jim smith-wright

Member

Jim that staff building is superb!! It looks like the plastic is placed on card (unless I'm mistaken). I've never scratch built a building before, but I'd love to convert the Metcalfe station to plastic.

Hiya

The base is foamboard with the plastic stuck to it. I use self aadhesive foamboard or double sided tape to laminate the materials together, this stops it warping as solvents dry.

The pic shows the marking out stage. I draw everything in Adobe Illustrator first and print it out. This is then taped to the foamboard and cut through. It does destroy the drawing thats why I have the spares in the picture.

This method saves all the marking out and the potential risk of errors an extra stage can bring. You should be able to use your metcalf building in the same way, perhaps covering the faces in plasticard and cutting out the windows from the back?

HTH

Jim

jim smith-wright

Member

Jim,

I am an avid Swiss train fan. I am looking into ways to make my own catenary system. Where do you purchase the insulators and other hardware that you use on your layout? Also, is there resources out there to help me with making the overhead wire? I have tried a couple different things, but they always turn out too frail or ugly.

Hi

All the OLE is scratchbuilt. The insulators are the only thing off the shelf (from sommerfeldt) and they are the weakest part. Luckily one of my friends has produced a small range of British insulators.

The contact wire is 10thou steel and is (I am told) used in the machine industry for cutting steel plates. Apparently the machines they use need miles of the stuff and big reels of it are thrown away. It is tensioned with springs in the bridges.

HTH

Jim

jim smith-wright

Member

Jim, Very nice modeling and outstanding trackwork! Such an ambitious project! My wife and I visited your country years ago and rode all around using a BritRail Pass. I even rode the Severn Valley. Wonderful good fun and friendly people, such as yourself. Thanks for sharing your techniques with us on this side of the pond. Keep the photos and ideas coming.

You are more than welcome. Thanks for the kind words.

The Severn Valley is within 25 miles of my house and about 5 miles from my fiancée's home. I have been on it several times but as is so often the case when something is right there I dont go on it enough. A large part of it has been closed for a year or so as heavy rains in 2007 washed some of it away. Due to the hard work of the volenteers and the donations of the public its all repaired now.

Regards

Jim

jim smith-wright

Member

why not use some spray on glue from a aerosol can so the paper doesn't move at all. I like the idea you have though, makes it look easy or easier.

Hi Steve

Like Spray mount? I didnt have any handy at the time but I would use it if I had it!

Regards

Jim

jim smith-wright

Member

Hi All

More progress on my building. Its now a box and is starting to feel like a proper model.

class 86 for scale.

on the prototype there is some clumsy concrete added to 1 end, I have replicated this with squadron filler.

Clumsy I know and I wont be adding brick courses to the small vertical walls. The reason why not is the model will be 3ft 3 inches from the front of the layout and will be visible through the bridge. in this instance the treatment of the corners is OK with me, if the building was right at the front of the layout I would have done all of the corners with my mount cutter. Even so significant corners such as the main ones will be done with the mount cutter for neatness.

BFN

Jim

More progress on my building. Its now a box and is starting to feel like a proper model.

class 86 for scale.

on the prototype there is some clumsy concrete added to 1 end, I have replicated this with squadron filler.

Clumsy I know and I wont be adding brick courses to the small vertical walls. The reason why not is the model will be 3ft 3 inches from the front of the layout and will be visible through the bridge. in this instance the treatment of the corners is OK with me, if the building was right at the front of the layout I would have done all of the corners with my mount cutter. Even so significant corners such as the main ones will be done with the mount cutter for neatness.

BFN

Jim

jim smith-wright

Member

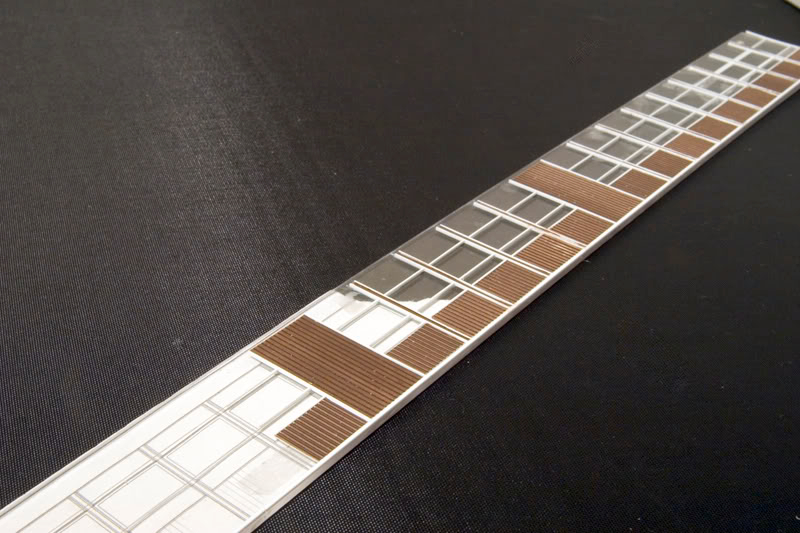

The beauty of this building, or rather its construction, is that I can use both of my construction methods in 1 structure. To start with a descision needs to be made if the building is predominantly brick/wood/metal or glass. If its mostly the fomer then I use foamboard as I have for the lower section shown so far. If I decide it has enough glass then the building is made from clear perspex with detail overlaid. It pays - especially with the window frames to colour them the correct colour first. Luckily in this instance they are white. The plan is stuck to the back of the perspex to save marking out. In this case the frames are 30x15 thou strip laid edge on.

Cheers

Jim

Cheers

Jim

Hathaway Browne

Intrepid Adventurer

Coming on great guns now!

Thanks for the insight on the construction method. Something for me to consider.

Thanks for the insight on the construction method. Something for me to consider.

jim smith-wright

Member

Hi All

Best laid plans…

The plan for today was to finish the panelling for the upper floor but I ran out of 15x30 thou strip! Oh well plenty more to be getting on with! The end walls have gained their surface texture and stairs while the beams that support the roof are now in. A bit more refinement around the windows and the basic structure of the upper floor is now done. Couldn't resist a little mock up or 2!

The funny little door is now done

View from the wolves end.

View from the other end, Gives a good impression of how the finished building will look I think.

Cheers

Jim

Best laid plans…

The plan for today was to finish the panelling for the upper floor but I ran out of 15x30 thou strip! Oh well plenty more to be getting on with! The end walls have gained their surface texture and stairs while the beams that support the roof are now in. A bit more refinement around the windows and the basic structure of the upper floor is now done. Couldn't resist a little mock up or 2!

The funny little door is now done

View from the wolves end.

View from the other end, Gives a good impression of how the finished building will look I think.

Cheers

Jim

jim smith-wright

Member

Hi All

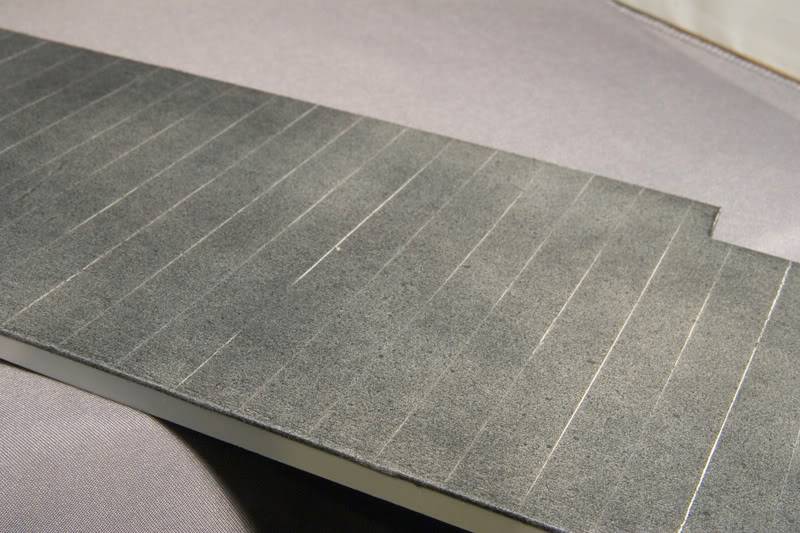

Had a play at doing roofing felt. The method is a single sheet of Tissue stuck down with double sided tape. This was then scored to represent different sheets and sprayed using Chris Nevards method of primer followed with a light dusting of black. Pretty pleased with the result so far, needs weathering yet though

Cheers

Jim

Had a play at doing roofing felt. The method is a single sheet of Tissue stuck down with double sided tape. This was then scored to represent different sheets and sprayed using Chris Nevards method of primer followed with a light dusting of black. Pretty pleased with the result so far, needs weathering yet though

Cheers

Jim

jim smith-wright

Member

Hi All

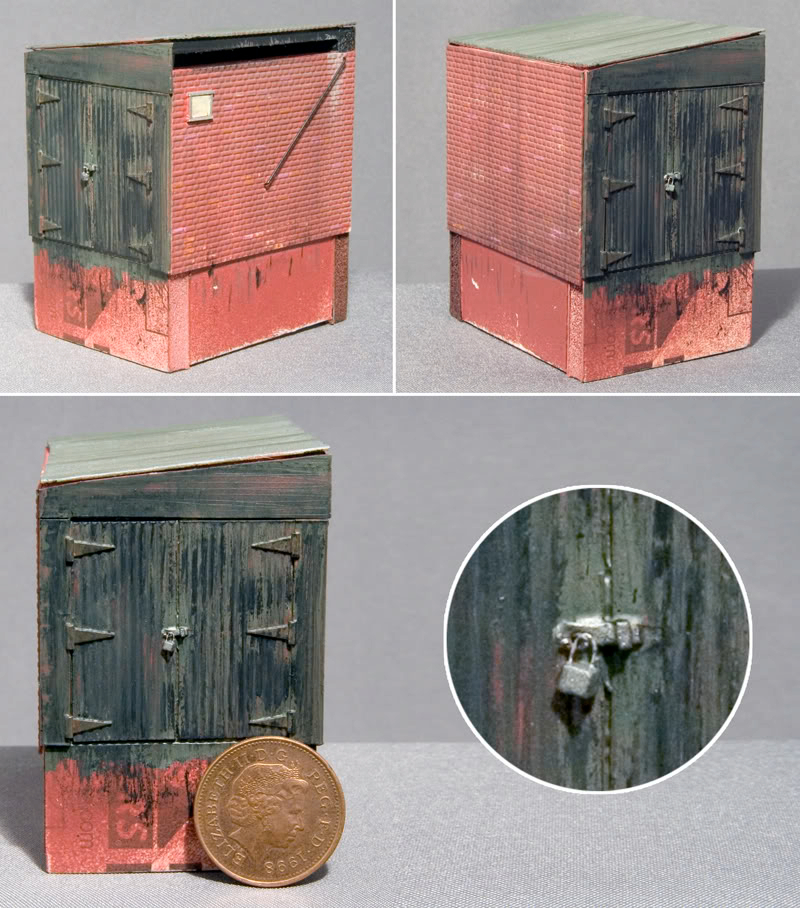

Been busying myself with the little shed I found on platform one. Makes a nice change to do a small quickie structure. Just for a bit of fun I had a go at making a rough representation of a 4mm scale padlock. Came out OK I thought! :twisted: :twisted:

English Penny for scale

Cheers

Jim

Been busying myself with the little shed I found on platform one. Makes a nice change to do a small quickie structure. Just for a bit of fun I had a go at making a rough representation of a 4mm scale padlock. Came out OK I thought! :twisted: :twisted:

English Penny for scale

Cheers

Jim

Last edited by a moderator:

jim smith-wright

Member

Yeah I Know - I think an english penny is about the same as a US one, about 20 mm in diameter

HTH

Jim

HTH

Jim

jim smith-wright

Member

Hi George

The padlock is just a piece of 40thou microstrip with a couple off holes drilled through it. A single strand of metal from normal electrical wire is then looped through the holes and secured with nail varnish.

HTH

Jim

The padlock is just a piece of 40thou microstrip with a couple off holes drilled through it. A single strand of metal from normal electrical wire is then looped through the holes and secured with nail varnish.

HTH

Jim

Affiliate Disclosure: We may receive a commision from some of the links and ads shown on this website (Learn More Here)