You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Troy's Still Untitled GN Cascade N-Scale line

- Thread starter troyphoto

- Start date

ModelRailroadForums.com is a free Model Railroad Discussion Forum and photo gallery. We cover all scales and sizes of model railroads. Online since 2002, it's one of the oldest and largest model railroad forums on the web. Whether you're a master model railroader or just getting started, you'll find something of interest here.

I'm diggin it!

Or, we're just following the contours of the landscape!

Troy

Good idea and good use of an item.

As Diet Dr. Pepper also is the offical sponsor of my fictional WRV&T RR, (Wisconsin River Valley and Terminal) I hope they gave you more then the official thank you response I got from them!

The layout has moved along pretty good. Have fun.

TomO

Affiliate Disclosure: We may receive a commision from some of the links and ads shown on this website (Learn More Here)

PRR Modeler

Well-Known Member

I buy rolls of plaster cast cloth on ebay or Amazon. You're right about WS being too expensive for large jobs.

troyphoto

Snarky Old Fart (in training)

Time for another update. Lots of progress, but slow going.

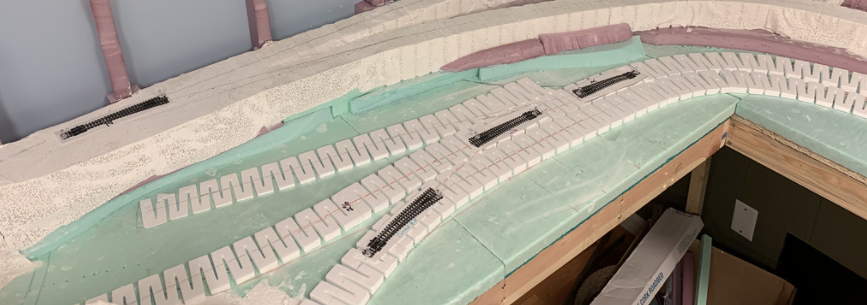

Got risers glued down for all but a few spur lines. Here's the mess of connecting lines over on the Misty Valley side. MV is to camera left. The line in the front, heads off to MV harbor on the lake. It loops around Berne and the stone quarry (and along a river - can you tell I like water features?) The center route in the image is the Mainline. To camera left, MV. To camera right, it also skirts (at a higher elevation) Berne and the gravel pit. Eventually it and the other line meet up, and head into Seattle.

The plaster clothed risers in the back loop around MV and enter from camera left (the center line).

Below: Misty valley from an aerial view. The pink area in the center of the image, is the tunnel over Mount Raven. I've painted the plaster cloth with diluted WS Earth Shade. The slopes around the perimeter are angle pieces of 2" pink foam cut from other projects. Don't throw those scraps out. I trimmed them and elevated them, and bent them to make my valley walls.

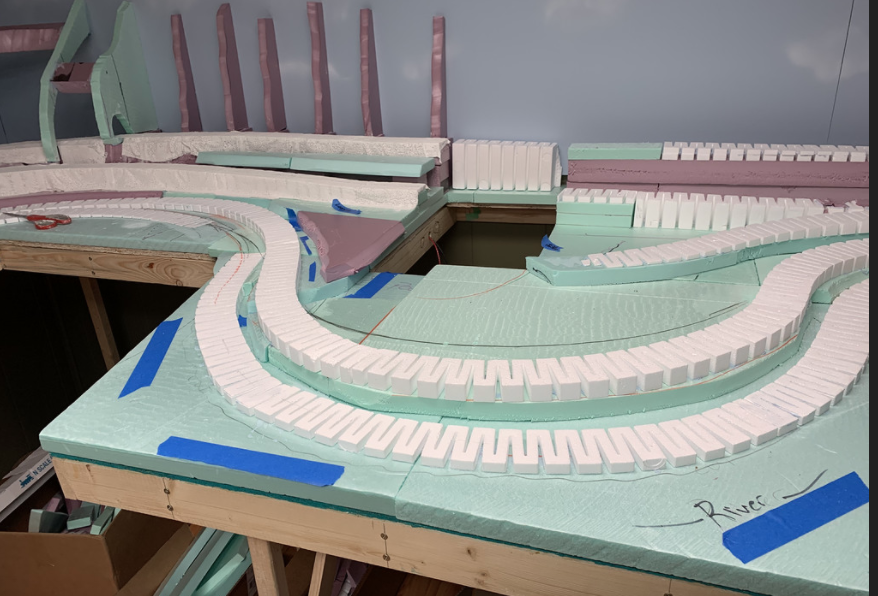

Below is the River Line (foreground) and the mainline just above that. Behind that is the spurline to Berne, then the lower and the upper main lines.

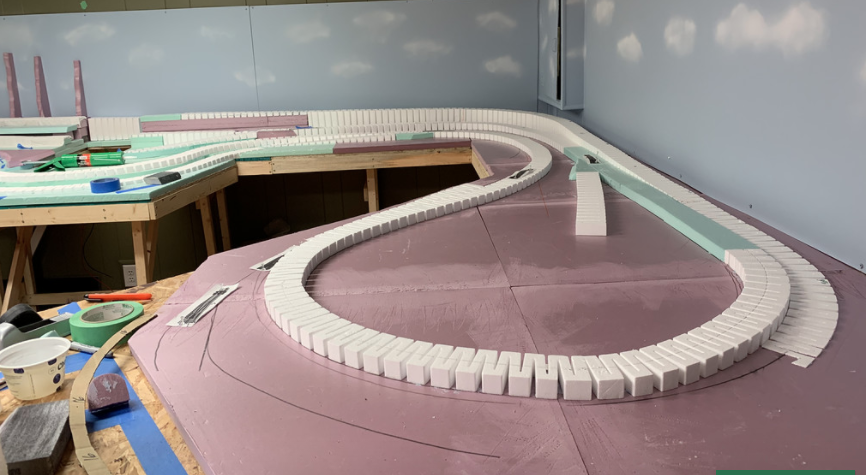

Next up is the Seattle End. The harbour is the wooden area to the left. The mainline diverges again. The Upper Main will take the three percent outer loop, even though it stays on the pink foam for most of the loop. The 2% grade will stay on the 1" riser for the loop, and then start the 2% grade at the far end of the green foam (right side).

And back to Misty Valley, with the soon to be underpass toward Berne

Got risers glued down for all but a few spur lines. Here's the mess of connecting lines over on the Misty Valley side. MV is to camera left. The line in the front, heads off to MV harbor on the lake. It loops around Berne and the stone quarry (and along a river - can you tell I like water features?) The center route in the image is the Mainline. To camera left, MV. To camera right, it also skirts (at a higher elevation) Berne and the gravel pit. Eventually it and the other line meet up, and head into Seattle.

The plaster clothed risers in the back loop around MV and enter from camera left (the center line).

Below: Misty valley from an aerial view. The pink area in the center of the image, is the tunnel over Mount Raven. I've painted the plaster cloth with diluted WS Earth Shade. The slopes around the perimeter are angle pieces of 2" pink foam cut from other projects. Don't throw those scraps out. I trimmed them and elevated them, and bent them to make my valley walls.

Below is the River Line (foreground) and the mainline just above that. Behind that is the spurline to Berne, then the lower and the upper main lines.

Next up is the Seattle End. The harbour is the wooden area to the left. The mainline diverges again. The Upper Main will take the three percent outer loop, even though it stays on the pink foam for most of the loop. The 2% grade will stay on the 1" riser for the loop, and then start the 2% grade at the far end of the green foam (right side).

And back to Misty Valley, with the soon to be underpass toward Berne

Patrick

What, me worry?

I like it! However after helping the grand son with his N-scale, it is a little small for my hands and eyes. You can get a lot of train in a small area though. We're still working through his wants and needs, but he can run trains. His favorite (or at least the one he runs the most) is a GN SW1200 that I bought an auction lot for and found it was N-scale when it arrived. It was in a 45 pound box of assorted train stuff both N and HO.

troyphoto

Snarky Old Fart (in training)

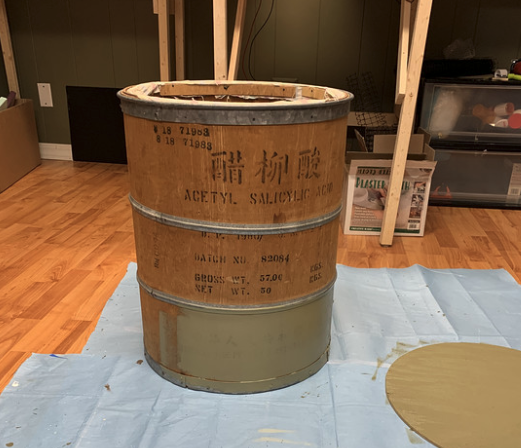

so, I've been working on a secret project for the Misty Valley Branch of the Great Northern's Cascade division.

Here are some in-progress photos

My father used to work at a factory where Anacin and Advil were made. Once, instead of 55 gal metal drums, their raw ingredients showed up in these wooden drums. Being president of his local, he managed to get his hands on one. For many years, it has sat in a corner, draped with a table cloth to hide the ugly wood, and serve as a side-table. Gave it to my daughter when we moved from Indiana, to California. As soon as we were back in Indiana, she returned it. Not even she wanted it.

But I saw a need!

Here's a hint:

NO. Not that.

In most of her glory!

Had to eyeball the color swatches at Lowes, but I believe I came pretty darn close to matching my Great Northern rolling stock. Here's the pic of a boxcar I took in for color reference.

So, what did we need in the train room at the Misty Valley division?

Welp... I drink a lot. Generate a lot of waste...

Here I am dropping the very first empty from the official beverage of the Misty Valley Branch into our new recycling bin. I got tired of carrying an armload of empties out of the basement each evening. This should give me enough to handle the every-other-week cycle that our recycling pickup runs on.

So, if you visit, you're welcome to help yourself to a beverage. Just make sure you deposit your empties. FOD Kills. Or something like that.

Hmmm.... I see the need for some large GN Graphics to be applied. Now, where can I find those...

Here are some in-progress photos

My father used to work at a factory where Anacin and Advil were made. Once, instead of 55 gal metal drums, their raw ingredients showed up in these wooden drums. Being president of his local, he managed to get his hands on one. For many years, it has sat in a corner, draped with a table cloth to hide the ugly wood, and serve as a side-table. Gave it to my daughter when we moved from Indiana, to California. As soon as we were back in Indiana, she returned it. Not even she wanted it.

But I saw a need!

Here's a hint:

NO. Not that.

In most of her glory!

Had to eyeball the color swatches at Lowes, but I believe I came pretty darn close to matching my Great Northern rolling stock. Here's the pic of a boxcar I took in for color reference.

So, what did we need in the train room at the Misty Valley division?

Welp... I drink a lot. Generate a lot of waste...

Here I am dropping the very first empty from the official beverage of the Misty Valley Branch into our new recycling bin. I got tired of carrying an armload of empties out of the basement each evening. This should give me enough to handle the every-other-week cycle that our recycling pickup runs on.

So, if you visit, you're welcome to help yourself to a beverage. Just make sure you deposit your empties. FOD Kills. Or something like that.

Hmmm.... I see the need for some large GN Graphics to be applied. Now, where can I find those...

gseritt

Well-Known Member

so, I've been working on a secret project for the Misty Valley Branch of the Great Northern's Cascade division.

Here are some in-progress photos

View attachment 120185

My father used to work at a factory where Anacin and Advil were made. Once, instead of 55 gal metal drums, their raw ingredients showed up in these wooden drums. Being president of his local, he managed to get his hands on one. For many years, it has sat in a corner, draped with a table cloth to hide the ugly wood, and serve as a side-table. Gave it to my daughter when we moved from Indiana, to California. As soon as we were back in Indiana, she returned it. Not even she wanted it.

But I saw a need!

Here's a hint:

View attachment 120186

NO. Not that.

In most of her glory!

View attachment 120187

Had to eyeball the color swatches at Lowes, but I believe I came pretty darn close to matching my Great Northern rolling stock. Here's the pic of a boxcar I took in for color reference.

View attachment 120188

So, what did we need in the train room at the Misty Valley division?

Welp... I drink a lot. Generate a lot of waste...

View attachment 120189

Here I am dropping the very first empty from the official beverage of the Misty Valley Branch into our new recycling bin. I got tired of carrying an armload of empties out of the basement each evening. This should give me enough to handle the every-other-week cycle that our recycling pickup runs on.

So, if you visit, you're welcome to help yourself to a beverage. Just make sure you deposit your empties. FOD Kills. Or something like that.

Hmmm.... I see the need for some large GN Graphics to be applied. Now, where can I find those...

I'm diggin it!

troyphoto

Snarky Old Fart (in training)

A new update!

Been laying cork road bed and ran into a problem. But didn't figure it out until after I let the caulk set.

Since I was using woodland scenics foam inclines and risers, when I had an underpass to cut for a downhill loop I left a gap in the riser for the lower end to pass through.

Problem was, I forgot to line up my track centerline from one side to the other, and test fit my steel girder bridge from Atlas. Turns out that even if I had, I would have been cursing. That section really needs to continue the curve. I hoped I could cheat it. Nope.

So, order a curved bride? I wanted one there with the Great Northern logo, since this is the area of first attention when someone comes to view the layout. But, I could only find Kato steel girder bridges, and no logos on them. Drat.

Plan B

(Always be willing to make up a plan B... especially when you do things like I do).

Time to make my own bridge. Wood or stone? While wood is still around in the transition era (1950s/60s) it doesn't fit with my vision for this layout. And, I really want to get that roadbed problem fixed sooner, rather than have me learn how to build a wooden bridge to fit. I haven't made one before. So stone it is. Basically, a very short tunnel.

Whoot! I've got some WS tunnel portals on hand.

Hmm... plaster... Never painted plaster before. The instruction say to use their earth shades. No mention of priming nor sealing like I would with resin or plastic... Hmmmm... Not sure how to handle that. Due to the long reach on the front side, I'll need to paint them before installing them. Thoughts? Who paints plaster parts like this? How do you handle it? Primer? or washes and shades straight onto the plaster?

So, what did I do to make the bridge? First a test fit of the plaster fascia to see what I was working with for depth and height. Yep. They're about perfect. Once I had the tunnel portal gap marked, inside and outside, I cut away my nicely laid cork roadbed from each side of the gap. Measured down 1-inch, and carved an abutment/step for the new foam piece to sit on. Used a hacksaw blade for the basic cuts.

Follow up with lining the "inside" of the tunnel with scrap foam bits to make "walls" a bit wider than the portal opening. Basically, I wanted a smoothish surface for paint later.

Then, I found a scrap piece of 1-inch foam already cut to the width of the WS risers. Hotwire cutter and knife, and got the foam "bridge" piece installed. Let the glue set, then came in with plaster cloth. One side of the "bridge" is a tad low, but I can raise it with joint compound. It will take several layers, though.

Here's the finished bridge/tunnel (WS portal propped up just for the photo - I'll install after painting.):

Also, I was concerned about being a klutz and dropping the plaster portals, so I traced one on some foamcore and made a couple of proxies to use while working on the construction:

They're not perfect, but good enough to keep the sizing on track.

If you've installed those plaster portals before, please share your favorite techniques for painting and weathering them below. Thanks!

Been laying cork road bed and ran into a problem. But didn't figure it out until after I let the caulk set.

Since I was using woodland scenics foam inclines and risers, when I had an underpass to cut for a downhill loop I left a gap in the riser for the lower end to pass through.

Problem was, I forgot to line up my track centerline from one side to the other, and test fit my steel girder bridge from Atlas. Turns out that even if I had, I would have been cursing. That section really needs to continue the curve. I hoped I could cheat it. Nope.

So, order a curved bride? I wanted one there with the Great Northern logo, since this is the area of first attention when someone comes to view the layout. But, I could only find Kato steel girder bridges, and no logos on them. Drat.

Plan B

(Always be willing to make up a plan B... especially when you do things like I do).

Time to make my own bridge. Wood or stone? While wood is still around in the transition era (1950s/60s) it doesn't fit with my vision for this layout. And, I really want to get that roadbed problem fixed sooner, rather than have me learn how to build a wooden bridge to fit. I haven't made one before. So stone it is. Basically, a very short tunnel.

Whoot! I've got some WS tunnel portals on hand.

Hmm... plaster... Never painted plaster before. The instruction say to use their earth shades. No mention of priming nor sealing like I would with resin or plastic... Hmmmm... Not sure how to handle that. Due to the long reach on the front side, I'll need to paint them before installing them. Thoughts? Who paints plaster parts like this? How do you handle it? Primer? or washes and shades straight onto the plaster?

So, what did I do to make the bridge? First a test fit of the plaster fascia to see what I was working with for depth and height. Yep. They're about perfect. Once I had the tunnel portal gap marked, inside and outside, I cut away my nicely laid cork roadbed from each side of the gap. Measured down 1-inch, and carved an abutment/step for the new foam piece to sit on. Used a hacksaw blade for the basic cuts.

Follow up with lining the "inside" of the tunnel with scrap foam bits to make "walls" a bit wider than the portal opening. Basically, I wanted a smoothish surface for paint later.

Then, I found a scrap piece of 1-inch foam already cut to the width of the WS risers. Hotwire cutter and knife, and got the foam "bridge" piece installed. Let the glue set, then came in with plaster cloth. One side of the "bridge" is a tad low, but I can raise it with joint compound. It will take several layers, though.

Here's the finished bridge/tunnel (WS portal propped up just for the photo - I'll install after painting.):

Also, I was concerned about being a klutz and dropping the plaster portals, so I traced one on some foamcore and made a couple of proxies to use while working on the construction:

They're not perfect, but good enough to keep the sizing on track.

If you've installed those plaster portals before, please share your favorite techniques for painting and weathering them below. Thanks!

Rico

BN Modeller

Nice save!

I’ve painted them with WS paints, dabbing it on with a sponge. Light colors followed by darker ones.

Here’s a good how to: https://woodlandscenics.woodlandscenics.com/show/video/ColorTunnelsWallsCulverts?start=65

I’ve painted them with WS paints, dabbing it on with a sponge. Light colors followed by darker ones.

Here’s a good how to: https://woodlandscenics.woodlandscenics.com/show/video/ColorTunnelsWallsCulverts?start=65

troyphoto

Snarky Old Fart (in training)

Today's update from yesterday (some timey-whiney-wibbly-wobbly update):

First: Painted the plaster tunnel portals. Used the WS stains/shades. Raw umber and grey. Then hit them with a drybrush of a light khaki color. Rattle can of matte finish sealer, then a final black wash (ink + alcohol + water). With a finish of a grey drybrush. Pic below is prior to the drybrush, midway through the sequence.

Had to run out to the craft store and pick up a pack of the 3 oz plastic bottles (like the craft paints come in). I always mix too much of the washes, so I figured I'd mix into the bottles, and pour back what I didn't use. That keeps the main, undiluted bottle undiluted. I'll just mix a new batch as needed in the smaller bottles.

I mixed my first batch of Sculptamold, and hit the inside of the tunnel to cover the plaster cloth.

Next, I installed the plaster portals with caulk as adhesive. I pressed too hard on the front one and cracked a leg off it. Ooops. CA glue took care of that, and I was more gentle installing it over the uneven plaster cloth.

Then I pressed sculptamold around the portal on the front side, and extended it to both sides. It may sound like I knew what I was doing, but no. I made it up as I went along. I mixed the first batch with too much at once. I used a yogurt cup as a scoop and went about three cup fulls... I had to keep adding water to keep it workable, and it's still damp this morning.

The backside of the scene also got it's portal and sculptamold up the side of Mount Raven. This was the second and third batches I mixed. Both were one cup of Sculptamold. I was adding "zinc" grey paint to the mix as I went to base color the stone.

Dealing with the trenches to both sides of the track yesterday, I realized that I wanted a gentler slope in the front of the scene, so it wasn't just a huge expanse of rock. This morning, while trying to get my coffee internals back to normal, I spent some time gluing in foam, and using some cast-off trimmings to fill in most of the trenches, and add some width to the sharp face of that curve.

I'll add plaster cloth this afternoon, then hit it with WS Earth Shade. These sections will get less rock, and more groundcover.

First: Painted the plaster tunnel portals. Used the WS stains/shades. Raw umber and grey. Then hit them with a drybrush of a light khaki color. Rattle can of matte finish sealer, then a final black wash (ink + alcohol + water). With a finish of a grey drybrush. Pic below is prior to the drybrush, midway through the sequence.

Had to run out to the craft store and pick up a pack of the 3 oz plastic bottles (like the craft paints come in). I always mix too much of the washes, so I figured I'd mix into the bottles, and pour back what I didn't use. That keeps the main, undiluted bottle undiluted. I'll just mix a new batch as needed in the smaller bottles.

I mixed my first batch of Sculptamold, and hit the inside of the tunnel to cover the plaster cloth.

Next, I installed the plaster portals with caulk as adhesive. I pressed too hard on the front one and cracked a leg off it. Ooops. CA glue took care of that, and I was more gentle installing it over the uneven plaster cloth.

Then I pressed sculptamold around the portal on the front side, and extended it to both sides. It may sound like I knew what I was doing, but no. I made it up as I went along. I mixed the first batch with too much at once. I used a yogurt cup as a scoop and went about three cup fulls... I had to keep adding water to keep it workable, and it's still damp this morning.

The backside of the scene also got it's portal and sculptamold up the side of Mount Raven. This was the second and third batches I mixed. Both were one cup of Sculptamold. I was adding "zinc" grey paint to the mix as I went to base color the stone.

Dealing with the trenches to both sides of the track yesterday, I realized that I wanted a gentler slope in the front of the scene, so it wasn't just a huge expanse of rock. This morning, while trying to get my coffee internals back to normal, I spent some time gluing in foam, and using some cast-off trimmings to fill in most of the trenches, and add some width to the sharp face of that curve.

I'll add plaster cloth this afternoon, then hit it with WS Earth Shade. These sections will get less rock, and more groundcover.

troyphoto

Snarky Old Fart (in training)

I like how you have the portals set at an angle.........nice little detail.....

Or, we're just following the contours of the landscape!

TLOC

Well-Known Member

so, I've been working on a secret project for the Misty Valley Branch of the Great Northern's Cascade division.

Here are some in-progress photos

View attachment 120185

My father used to work at a factory where Anacin and Advil were made. Once, instead of 55 gal metal drums, their raw ingredients showed up in these wooden drums. Being president of his local, he managed to get his hands on one. For many years, it has sat in a corner, draped with a table cloth to hide the ugly wood, and serve as a side-table. Gave it to my daughter when we moved from Indiana, to California. As soon as we were back in Indiana, she returned it. Not even she wanted it.

But I saw a need!

Here's a hint:

View attachment 120186

NO. Not that.

In most of her glory!

View attachment 120187

Had to eyeball the color swatches at Lowes, but I believe I came pretty darn close to matching my Great Northern rolling stock. Here's the pic of a boxcar I took in for color reference.

View attachment 120188

So, what did we need in the train room at the Misty Valley division?

Welp... I drink a lot. Generate a lot of waste...

View attachment 120189

Here I am dropping the very first empty from the official beverage of the Misty Valley Branch into our new recycling bin. I got tired of carrying an armload of empties out of the basement each evening. This should give me enough to handle the every-other-week cycle that our recycling pickup runs on.

So, if you visit, you're welcome to help yourself to a beverage. Just make sure you deposit your empties. FOD Kills. Or something like that.

Hmmm.... I see the need for some large GN Graphics to be applied. Now, where can I find those...

Troy

Good idea and good use of an item.

As Diet Dr. Pepper also is the offical sponsor of my fictional WRV&T RR, (Wisconsin River Valley and Terminal) I hope they gave you more then the official thank you response I got from them!

The layout has moved along pretty good. Have fun.

TomO

Affiliate Disclosure: We may receive a commision from some of the links and ads shown on this website (Learn More Here)