After much dithering, I finally bought myself an inexpensive miter saw to build the benchwork. If I am going to be doing this more often in the future, I figured it makes sense to invest in some better tools. I used a jigsaw to cut the lumber for the legs for Woodlawn Industrial Park and I have to say that it did not come out looking good at all. It's very hard to make neat square cuts with a jigsaw as it vibrates so much.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Town and country - automated N-scale layout

- Thread starter kleiner

- Start date

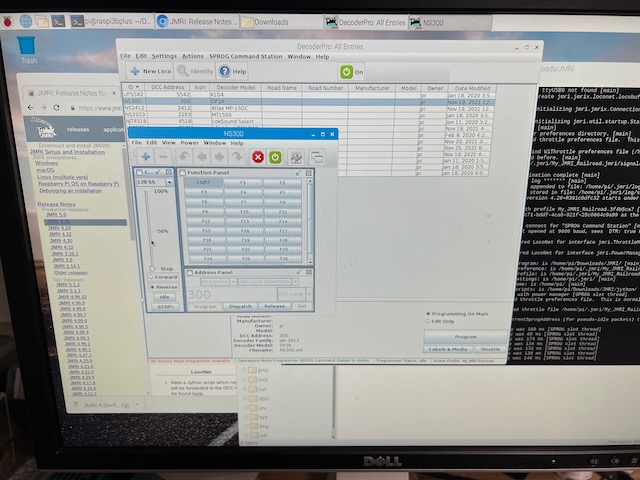

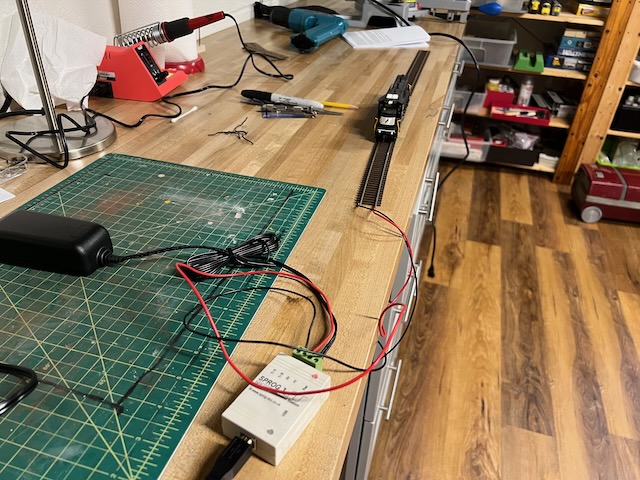

I took a loco out for a test drive using the Sprog and thankfully, everything worked on the first go. I already had JMRI installed on the Raspberry Pi so my only task was to update it to 4.26 (which is the last version that will work with Java 8). I have been using this installation of JMRI to program my locomotives so I already had roster entries for them.

Using the DecoderPro app, I brought up a throttle for my Genset switcher.

And I was able to get the loco to creep forward and backwards and turn the light on and off.

Using the DecoderPro app, I brought up a throttle for my Genset switcher.

And I was able to get the loco to creep forward and backwards and turn the light on and off.

Now to get on with the actual task of designing the layout. The main question is about its size: Until now I have been thinking it would be 2 ft by 5 ft. But now I'm wondering whether I should extend the layout by a foot and make it 2 ft by 6 ft. When transporting this layout, I would anyway need to fold down the rear sets in my small SUV. So it shouldn't make any difference if the layout is a foot longer.

GuilfordRailman

Well-Known Member

Definitely go with the extra foot!Now to get on with the actual task of designing the layout. The main question is about its size: Until now I have been thinking it would be 2 ft by 5 ft. But now I'm wondering whether I should extend the layout by a foot and make it 2 ft by 6 ft. When transporting this layout, I would anyway need to fold down the rear sets in my small SUV. So it shouldn't make any difference if the layout is a foot longer.

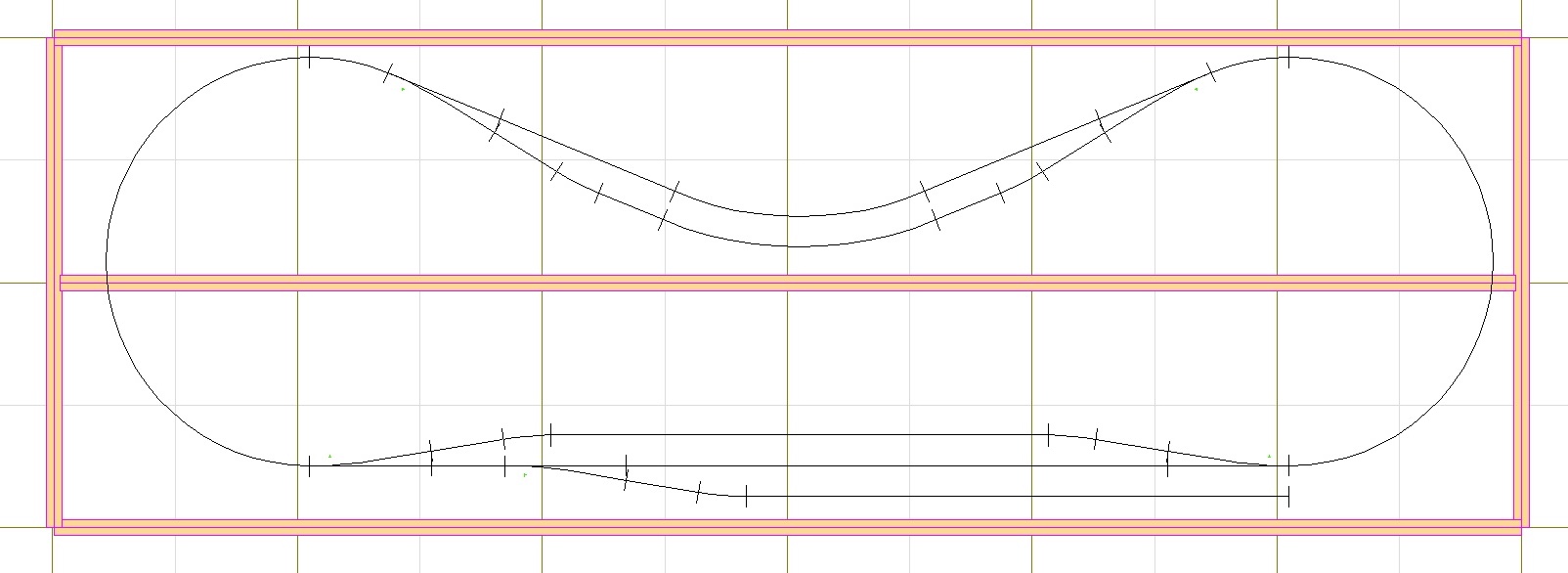

Following @GuilfordRailman 's suggestion, I have decided that I will extend the layout by a foot so I have been trying out some ideas. My current thinking is to have two separate scenes with a scenic divider in the middle. The top half of this design will be some kind of a rural or mountainous scene and the lower half will be a town.

I have the miter saw so I now feel sufficiently confident to start with the benchwork. I will have two L-girders made of 1x3 and 1x2. The cross beams will be 1x3. I did a rough calculation and found that the lumber will weight about 20 pounds which is roughly what I want.

I have the miter saw so I now feel sufficiently confident to start with the benchwork. I will have two L-girders made of 1x3 and 1x2. The cross beams will be 1x3. I did a rough calculation and found that the lumber will weight about 20 pounds which is roughly what I want.

skyliner

Well-Known Member

After much dithering, I finally bought myself an inexpensive miter saw to build the benchwork. If I am going to be doing this more often in the future, I figured it makes sense to invest in some better tools. I used a jigsaw to cut the lumber for the legs for Woodlawn Industrial Park and I have to say that it did not come out looking good at all. It's very hard to make neat square cuts with a jigsaw as it vibrates so much.

Good call on the miter saw, I would say it's one of the most useful tools I acquired for bench work and other later projects around the home. Do you have a stand for it? You can find relatively inexpensive fold-up ones at places like Harbor Freight Tools or even on Amazon. And make sure you have some sort of dust mitigation system if you're cutting indoors. You can probably get away with attaching a shop vac to the back of the saw, unless you're doing lots of cutting at the same time.

An alternative of course is to build your own saw stand.

As it happens, I just received and assembled a miter saw stand that I found on Amazon. I tried it out and it seems to be functional. Good point about dust collection - I have a shop-vac that and I will attach it to the saw. Its a good thing I have vinyl flooring that's easy to vacuum!Good call on the miter saw, I would say it's one of the most useful tools I acquired for bench work and other later projects around the home. Do you have a stand for it? You can find relatively inexpensive fold-up ones at places like Harbor Freight Tools or even on Amazon. And make sure you have some sort of dust mitigation system if you're cutting indoors. You can probably get away with attaching a shop vac to the back of the saw, unless you're doing lots of cutting at the same time.

An alternative of course is to build your own saw stand.

[I changed the name of the thread to better reflect the theme of layout]

I just got around to actually the space available in the back of my SUV and discovered that the layout can't be longer than 5' 6" with the rear seats folded down. Looks like I will need to revise my plans a little - thankfully this not a show stopper!

I just got around to actually the space available in the back of my SUV and discovered that the layout can't be longer than 5' 6" with the rear seats folded down. Looks like I will need to revise my plans a little - thankfully this not a show stopper!

JeffH

Well-Known Member

I made a cyclone dust collection system out of a couple 5 gallon buckets and some inexpensive PVC fittings.

Works great for sawdust collection in my shop! It intercepts a good 90+% of the sawdust before it ever gets into your shopvac, which really helps with a lot of things, like extending the time you have before having to empty the shopvac, extending the life of the filter inside your shopvac, and it even reduses the amount of dust that gets through the filter and blown back into your space.

DIY sawdust collector

Works great for sawdust collection in my shop! It intercepts a good 90+% of the sawdust before it ever gets into your shopvac, which really helps with a lot of things, like extending the time you have before having to empty the shopvac, extending the life of the filter inside your shopvac, and it even reduses the amount of dust that gets through the filter and blown back into your space.

DIY sawdust collector

This is a great idea - noted for the future!I made a cyclone dust collection system out of a couple 5 gallon buckets and some inexpensive PVC fittings.

Works great for sawdust collection in my shop! It intercepts a good 90+% of the sawdust before it ever gets into your shopvac, which really helps with a lot of things, like extending the time you have before having to empty the shopvac, extending the life of the filter inside your shopvac, and it even reduses the amount of dust that gets through the filter and blown back into your space.

DIY sawdust collector

This is a great idea - noted for the future!I made a cyclone dust collection system out of a couple 5 gallon buckets and some inexpensive PVC fittings.

Works great for sawdust collection in my shop! It intercepts a good 90+% of the sawdust before it ever gets into your shopvac, which really helps with a lot of things, like extending the time you have before having to empty the shopvac, extending the life of the filter inside your shopvac, and it even reduses the amount of dust that gets through the filter and blown back into your space.

DIY sawdust collector

Finally made some progress on the benchwork! I built the L-girders first and then cut the cross beams. The miter saw really came in useful here as I was able to cut all of them to the exact same length. I have to say though that this lumber I got was pretty bad. I need to go to a good lumber yard next time.

I haven't screwed the cross members in place because I don't know the exact location if the turnouts as yet. I need to redo the design in 3rd Planit (the CAD program that I'm using) to account for the reduced length (6 inches shorter).

I haven't screwed the cross members in place because I don't know the exact location if the turnouts as yet. I need to redo the design in 3rd Planit (the CAD program that I'm using) to account for the reduced length (6 inches shorter).

GuilfordRailman

Well-Known Member

My first obstacle for my current layout build was using cheaper lumber. It made the build a little tricky since the boards were rough. Good lumber makes all the difference!I have to say though that this lumber I got was pretty bad.

It seemed ok in the store but only when I got home and started cutting it, did I realize just how bad the lumber was. I built the L-girders with the best pieces in the set and seems ok. Keeping my fingers crossed that it turns out ok.My first obstacle for my current layout build was using cheaper lumber. It made the build a little tricky since the boards were rough. Good lumber makes all the difference!

Twenty five years ago when I built my first layout, there was a great independent lumber store not far from my house. I bought all of the lumber from there but sadly it shut down when the owner retired. My neighbor just told me about a lumber depot about ten miles away - I may go to investigate.

GuilfordRailman

Well-Known Member

Independent mom and pop place’s are the places to shop. Hopefully it works out!

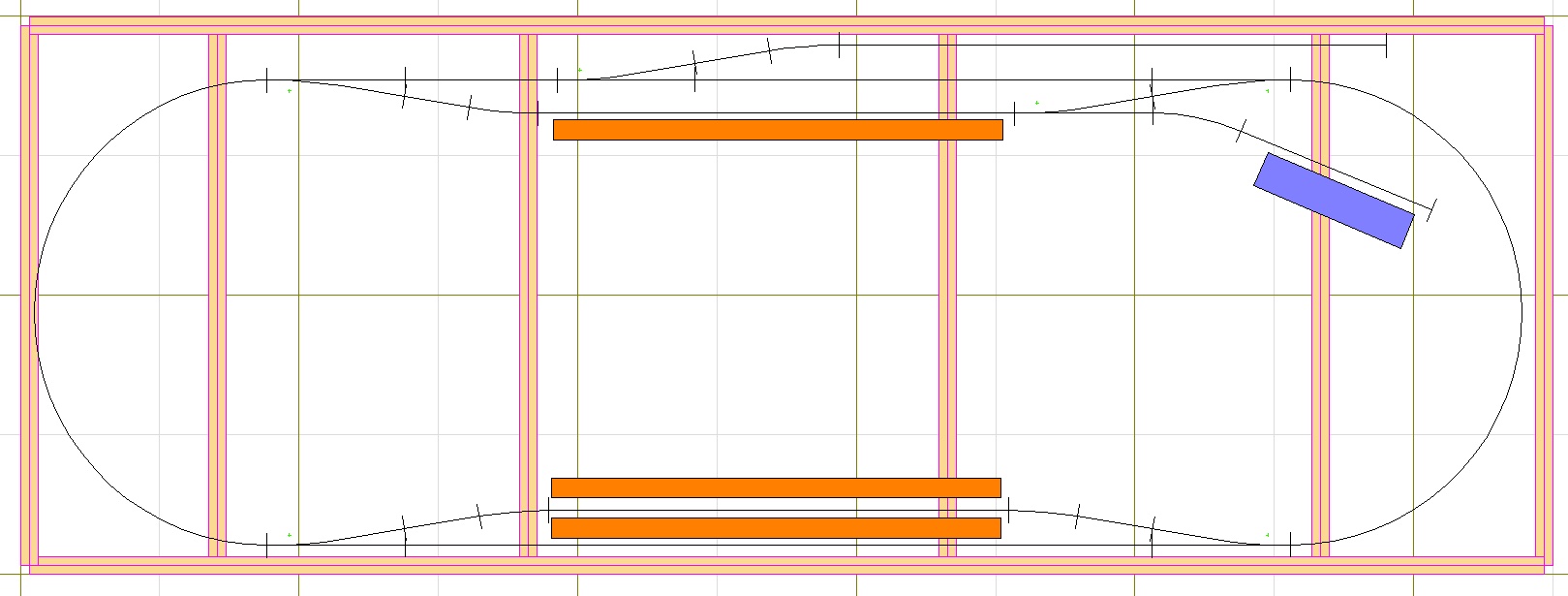

The layout buildup is going to get a little slow for the next few days while I wrestle with the final track layout. A few things I have been doing:

1. Tried out various sample trains to see what I could fit in about 20 inches, which is the expected length of the passing sidings.

2. Trying out some track plans. Similar to what you may have seen with my other layout (Woodlawn Industrial Park), I spend a lot of time thinking about alternatives before committing to a plan. The orange rectangles represent station platforms since there will be passenger trains running on this layout. The purple rectangle is some kind of an industry which will be for show to break the monotony. I don't want the two sides to look identical. I am not intending to do any switching operations. You can expect to see a lot of ideas as I try them out

One great thing about 3rd Planit is that I can figure out the best location for the cross beams in the benchwork.

1. Tried out various sample trains to see what I could fit in about 20 inches, which is the expected length of the passing sidings.

2. Trying out some track plans. Similar to what you may have seen with my other layout (Woodlawn Industrial Park), I spend a lot of time thinking about alternatives before committing to a plan. The orange rectangles represent station platforms since there will be passenger trains running on this layout. The purple rectangle is some kind of an industry which will be for show to break the monotony. I don't want the two sides to look identical. I am not intending to do any switching operations. You can expect to see a lot of ideas as I try them out

One great thing about 3rd Planit is that I can figure out the best location for the cross beams in the benchwork.

GuilfordRailman

Well-Known Member

Looking great! Can’t remember if you mentioned this previously but what time period are you modeling?The layout buildup is going to get a little slow for the next few days while I wrestle with the final track layout. A few things I have been doing:

1. Tried out various sample trains to see what I could fit in about 20 inches, which is the expected length of the passing sidings.

View attachment 149009

2. Trying out some track plans. Similar to what you may have seen with my other layout (Woodlawn Industrial Park), I spend a lot of time thinking about alternatives before committing to a plan. The orange rectangles represent station platforms since there will be passenger trains running on this layout. The purple rectangle is some kind of an industry which will be for show to break the monotony. I don't want the two sides to look identical. I am not intending to do any switching operations. You can expect to see a lot of ideas as I try them out

View attachment 149010

One great thing about 3rd Planit is that I can figure out the best location for the cross beams in the benchwork.

skyliner

Well-Known Member

This layout is going to feature the Tomytec Bus system. Its like the Faller car system except for N-scale. It runs really well! I took out the bus roadway pieces and set it up for a test run. Ran beautifully after lying in a box for a couple of years.

Pretty nifty. Japan has always had some cool toy and hobby stuff. I've always wondered why Tomy/Tomica/Plarail has never caught on more here in North America. IMO, their blue plastic snap-together track and battery powered trains are one of the best kids' toy trains, yet aside from a few sets on Amazon, or shipping from overseas, they are nearly impossible to find in the US.