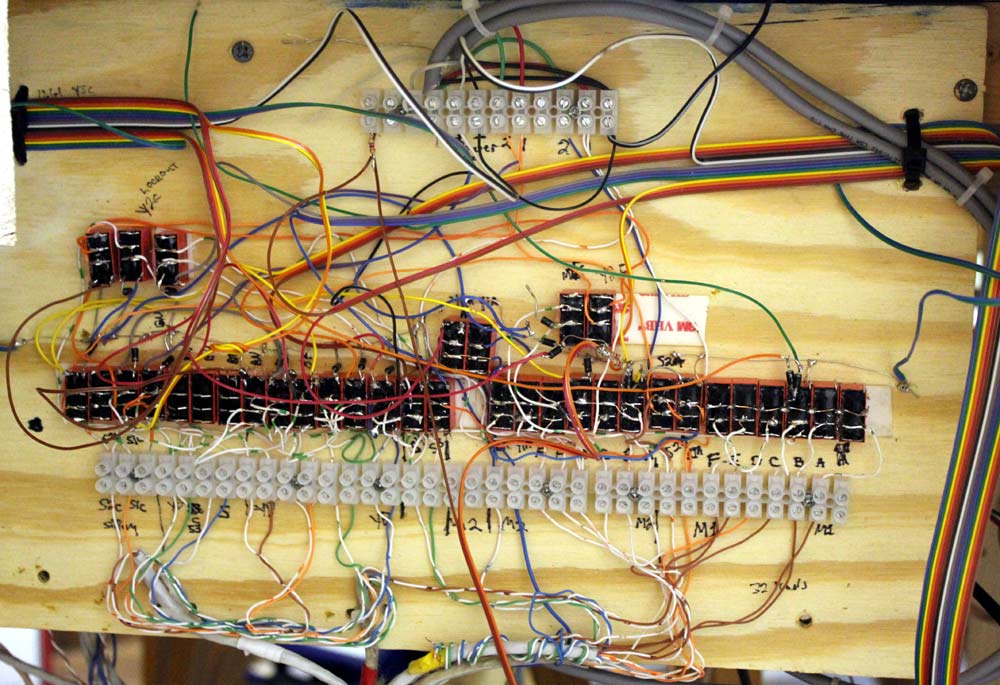

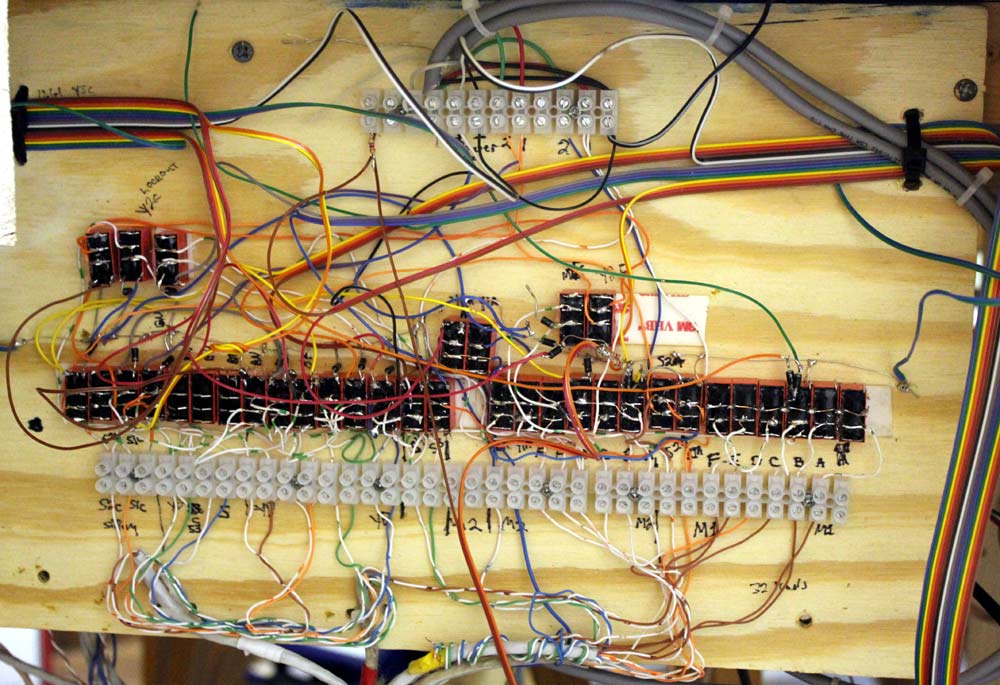

I just completed the logic board of my DC layout. It does everything I wanted with diode and relay logic, plus I really enjoyed building it. It is dead bug style (parts mounted on their backs) with point-to-point rat's nest wiring. Perfect to scare people.

http://www.w8ji.com/Model train layout wiring.htm

http://www.w8ji.com/Model train layout wiring.htm