RIGuyUK

Well-Known Member

Hi All

Last night I replaced cracked gears in 2 P2K loco's that I bought cheaply, I thought I'd make a tutorial to show those who may be hesitant to do this, just to show how easy and quick it is.

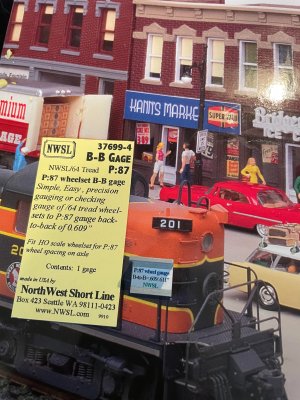

To start with, here are the culprits, along with the tools used...

GP7 GN

GP18 RI

Athearn 60024 Gears

Flat head jewellers screwdriver

2.3mm (3/32) reamer in a pin chuck

HO Back to Back gauge

Synthetic oil

I found the axle shafts to be slightly larger than the gear bore, hence the reamer.

Grab your choice of beverage and as always, work in a good light.

First thing first we need to take off the truck sideframes and insulating plates, using the flat head screwdriver to prize these out from the bogie frames, they can be seen in the background.

Next we have to remove the keeper plates from the bottom of the trucks, using the screwdriver again to prise the lugs away - I insert at the front of the keeper plate, towards one side, then gently twist which will release the lug. This exposes the gears...

Lift each wheelset out and examine the plastic gear for any signs of a crack...you can clearly see the crack on each shoulder of the gear below...

The wheels and stub axles simply pull out, throw the old gear - or keep to add to a gondola load!

Using a reamer, in this case 2.3mm, gently open up the bore, do this from both sides...

Clear any swarf way then fit the stub axles into the gear...

Check the back to back measurement on your gauge...

And replace the axle back into the truck frame...

Repeat for all other axles (I replace all gears even if only one is cracked), then add a spot of oil to each exposed gear...

Refit the keeper plates, run the loco on a rolling road to distribute the oil and to check all is well, re-assemble the insulating plates and sideframes and enjoy your reborn locomotive!

I hope this guide is useful and dispels any fears of how difficult it sounds. To do the 2 loco's it took me less than 20 minutes, including re-assembly

Last night I replaced cracked gears in 2 P2K loco's that I bought cheaply, I thought I'd make a tutorial to show those who may be hesitant to do this, just to show how easy and quick it is.

To start with, here are the culprits, along with the tools used...

GP7 GN

GP18 RI

Athearn 60024 Gears

Flat head jewellers screwdriver

2.3mm (3/32) reamer in a pin chuck

HO Back to Back gauge

Synthetic oil

I found the axle shafts to be slightly larger than the gear bore, hence the reamer.

Grab your choice of beverage and as always, work in a good light.

First thing first we need to take off the truck sideframes and insulating plates, using the flat head screwdriver to prize these out from the bogie frames, they can be seen in the background.

Next we have to remove the keeper plates from the bottom of the trucks, using the screwdriver again to prise the lugs away - I insert at the front of the keeper plate, towards one side, then gently twist which will release the lug. This exposes the gears...

Lift each wheelset out and examine the plastic gear for any signs of a crack...you can clearly see the crack on each shoulder of the gear below...

The wheels and stub axles simply pull out, throw the old gear - or keep to add to a gondola load!

Using a reamer, in this case 2.3mm, gently open up the bore, do this from both sides...

Clear any swarf way then fit the stub axles into the gear...

Check the back to back measurement on your gauge...

And replace the axle back into the truck frame...

Repeat for all other axles (I replace all gears even if only one is cracked), then add a spot of oil to each exposed gear...

Refit the keeper plates, run the loco on a rolling road to distribute the oil and to check all is well, re-assemble the insulating plates and sideframes and enjoy your reborn locomotive!

I hope this guide is useful and dispels any fears of how difficult it sounds. To do the 2 loco's it took me less than 20 minutes, including re-assembly