Hi guys , its been a while since I have been able to " play trains " but now it looks like I am finally going to get to retire and enjoy some much needed unwind time . I have also taken over ( with permission from SWMBO ) a larger room . I thought that would solve a lot of problems for me but for every one it solved it created a different one . The room is 14 X 19 1/2 feet and no matter how I turn and twist the track , I cant come close to what I would really like . I think I would be able to get real close with a multi deck layout , but in looking into a helix I run across the same thing every time , it takes up to much room and it takes the trains out of sight for to long . Then I thought that maybe a no-lix was the answer but for the life of me I cant seem to figure out how to hide it and still have access to it . A no-lix would take up less room I think , but the trains would still be out of site for a good amount of time . As a compromise I think I could give up some viewing time if I could gain some real estate . What I want is a long run through the mountains and over lots of trestle bridges ( which could be on the top level ) but also a lot of operations (which could be on the bottom level ) but connecting the two levels is where I am running in the wall . I would like somewhere around 16-18 inches of separation and that is creating the problem for my very limited imagination . Any ideas would be greatly appreciated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ready to go but cant design a layout I am happy with

- Thread starter jim81147

- Start date

KB02

Well-Known Member

As I continue to expand my layout, I often think about just starting from scratch as I really like the creative process. You have a wonderful blank slate in front of you.

As a suggestion, might I offer up the possibility of learning to live with a helix? My layout drops a little over a foot while going around a 30' room. You really don't have a lot of room for a gradual decline without going with several loops or severe grades (although... finding a way to work several loops in could be fun).

My layout drops a little over a foot while going around a 30' room. You really don't have a lot of room for a gradual decline without going with several loops or severe grades (although... finding a way to work several loops in could be fun).

Another suggestion would be to commission a track plan from someone. It would cost a bit of money, probably, but it might help solve your dilemma.

For what it's worth, I like your thinking of both the operations and the trestles.

As a suggestion, might I offer up the possibility of learning to live with a helix?

Another suggestion would be to commission a track plan from someone. It would cost a bit of money, probably, but it might help solve your dilemma.

For what it's worth, I like your thinking of both the operations and the trestles.

santafewillie

Same Ol' Buzzard

A no-lix doesn't need to be hidden. Matter of fact, the less hidden track the better for maintenance purposes as well as the fact that any issues will occur in the hidden part.

On the other hand, 14' x 19 1/2' is a good sized area and a helix while taking up some space, would more than return that space with a second level.

I have two levels and plans possibly for an external helix, (out of the train room itself) but for the time being I just run on the two levels without interconnecting.

On the other hand, 14' x 19 1/2' is a good sized area and a helix while taking up some space, would more than return that space with a second level.

I have two levels and plans possibly for an external helix, (out of the train room itself) but for the time being I just run on the two levels without interconnecting.

Willie , I agree with you that it WILL happen and it WILL ALWAYS BE ON A HIDDEN AREA . Unfortunately the thought of a constant grade running along the wall down three sides of the layout is not that appealing to me and as KB says I am not sure that even using all the available wall space I have would give me the separation I want . I have never seen a helix in person , only on video's . Where it gets confusing for me is I read an article by a gentleman whose name is , I believe, Joe ,and it states that a helix radius needs to be a minimum of 2 1/2 times the length of your longest car and 3 times is even better for trouble free operating . I model the transition era so my cars are relatively short and so are the engines . If that formula is correct , that means that I could get by with a 19 inch radius . I would even have no problem building a helix with a 24 inch radius , but when asking questions and opinions the lions share come back with 30 inches minimum and thats even sketchy . I just dont have the room for that large a helix . Thats why I am looking for some feedback from people who either have them or operate on them to hear if they really are as troublesome as some folks say.

GeeTee

Well-Known Member

I have work on a few helices over the years . The minimum radius that your calculating is probably for an oval-lix .In an ideal world you want the grade to be as shallow as you can make it , ~2% at max and 1.5% or less if possible .

a 30" radius helix with 5mm poplar sub bed ,no roadbed and code 100 Atlas will yield around 2 5/8 - 2 3/4 " clearance, but thats still less than the NMRA Standard. Thats enought barely to get things like Super Liners and High Cubes thru but not enough for 200 ton cranes (they'll get stuck) but shallow enough to drag 15 to 20 cars up with a single weighted Athearn F .

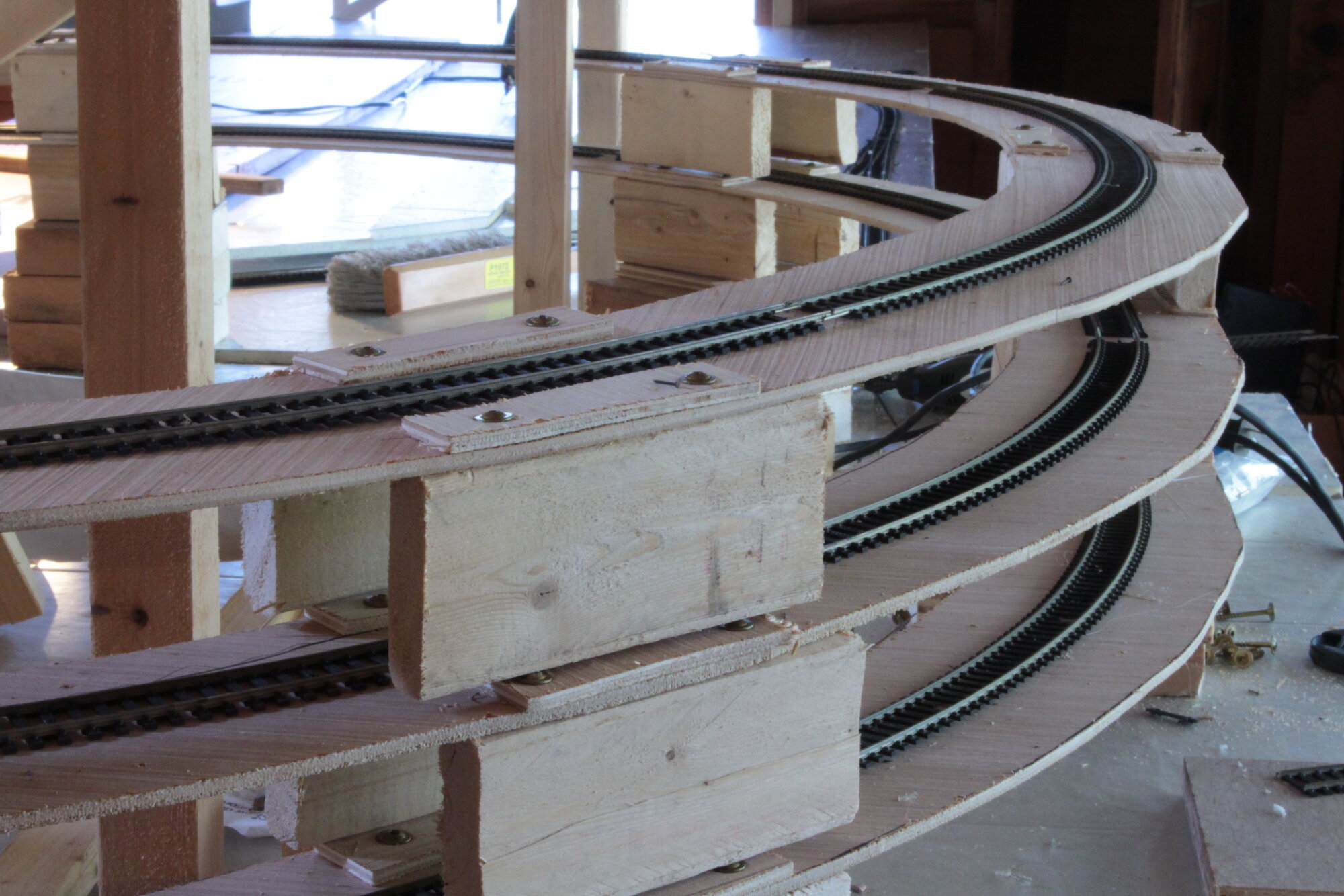

A 30" radius helix under construction. ( actually a slight oval-lix 30" r with 6" straight ~200" lap length) . Layout space is ~30 x 14. Layer to layer distance is ~ 3 " , rail head to bottom of the sub bed is 2 5/8 to 2 3/4.

To get the same with a 24 inch radius , you'll need to add 4ft straight sections( 200 " lap length X 1.5% grade = 3" bed to bed or ~2 3/4" rail to bed clearance.

If you build a helix use a curve gauge , and put it where it can be accessed on 3 sides , so you don't have to crawl under .

at 24" you probably won't have issues with diesels but some 8 couple steam may give issues , 30 is pretty much the minium for 10 coupled steam.

a 30" radius helix with 5mm poplar sub bed ,no roadbed and code 100 Atlas will yield around 2 5/8 - 2 3/4 " clearance, but thats still less than the NMRA Standard. Thats enought barely to get things like Super Liners and High Cubes thru but not enough for 200 ton cranes (they'll get stuck) but shallow enough to drag 15 to 20 cars up with a single weighted Athearn F .

A 30" radius helix under construction. ( actually a slight oval-lix 30" r with 6" straight ~200" lap length) . Layout space is ~30 x 14. Layer to layer distance is ~ 3 " , rail head to bottom of the sub bed is 2 5/8 to 2 3/4.

To get the same with a 24 inch radius , you'll need to add 4ft straight sections( 200 " lap length X 1.5% grade = 3" bed to bed or ~2 3/4" rail to bed clearance.

If you build a helix use a curve gauge , and put it where it can be accessed on 3 sides , so you don't have to crawl under .

at 24" you probably won't have issues with diesels but some 8 couple steam may give issues , 30 is pretty much the minium for 10 coupled steam.

KB02

Well-Known Member

So in short (and I'll admit: this is for my own clarification): The wider the radius => the shallower the grade & the greater the separation (roof height) between levels?

I have one loop on my layout, which is mostly uni-directional, that is an 18" radius loop. Locos almost always run down the grade, so no problems. When they turn around and run the other direction, I am limited to the number of cars I can pull before adding more locos.

I have one loop on my layout, which is mostly uni-directional, that is an 18" radius loop. Locos almost always run down the grade, so no problems. When they turn around and run the other direction, I am limited to the number of cars I can pull before adding more locos.

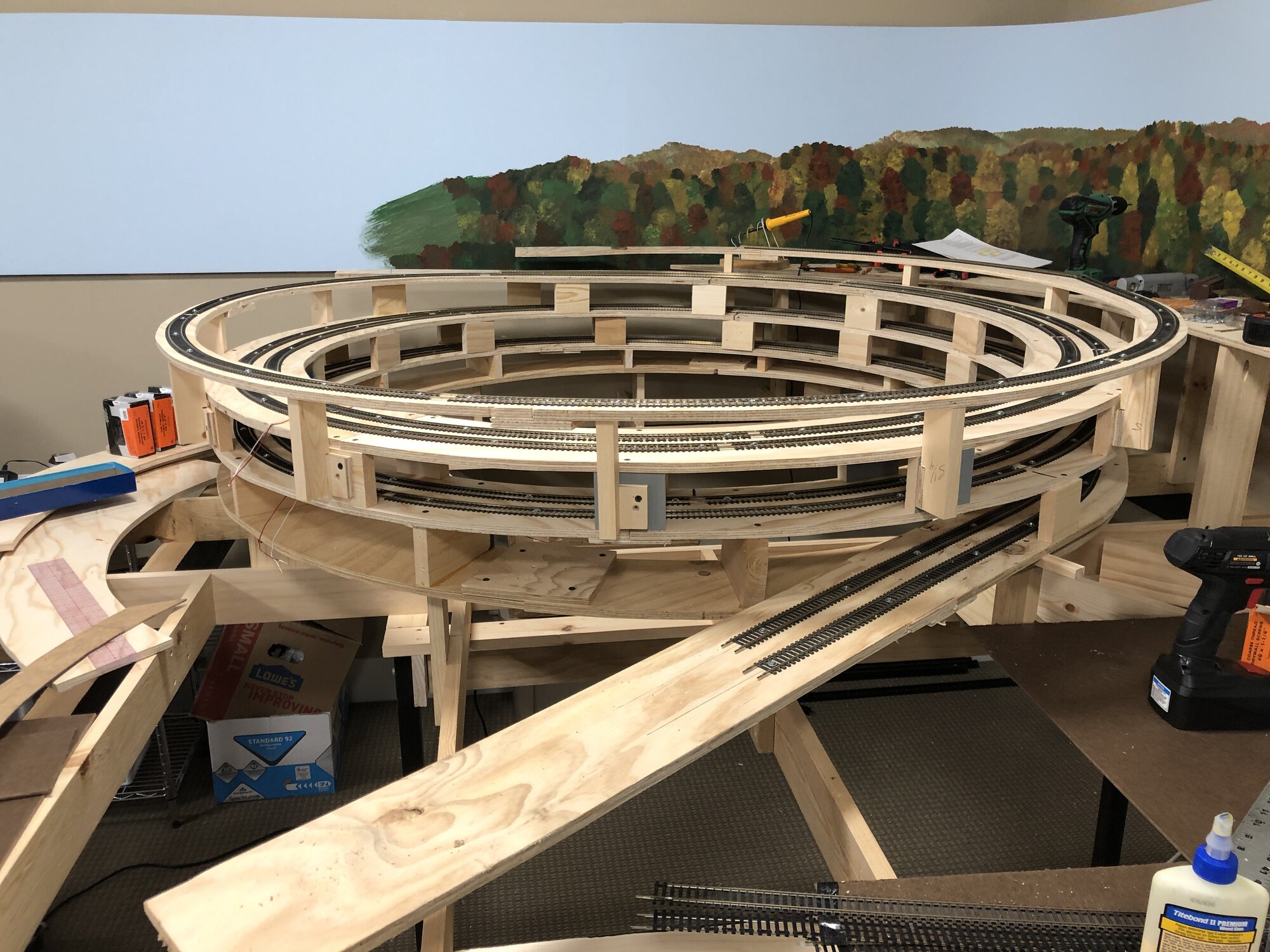

I have two (technically 3 helices) on my layout (two helix structures, but one has two separate routes on the same roadbed). All are hidden. I used the same roadbed and spacer method as shown above, except for the spacers and screw heads sitting under the blocks in the picture above. I also use 1/2 plywood for the roadbed and cut all my spacer blocks to the width I needed to get the grade I wanted. I also had a bit of weirdness in that on the double helix I had to get the inside track to the outside, so I ran it around on one additional loop.

Here is the base for the helix. I use a base so I have a level place to start building from.

I then cut a series of stepped blocks to establish the grade. They are glued to the base.

Each turn is applied by screwing the roadbed arcs to the blocks, track is laid as I go. I use 1/2" #6 pan head screws on the track centerline to screw the track to the roadbed. If I later need to adjust or remove track I can unscrew or loosen the screws and then tighten them back up again. Once the track is in place I glue spacer blocks to the outside of the roadbed. Then the next layer of roadbed is applied and screwed to the spacer blocks. I make the roadbed joints fall on the spacer blocks so they become the splice blocks for each turn.

Finally I use risers to lift the base and the whole helix up to the final height. You might also notice I added that "extra" turn to the outside of the helix getting the inside turn to the outside.

.

.

A helix has four design components, the radius, the spacing between turns, the grade and the total rise. It has to be designed to take all three of those into account. The first two determine the grade. Personally I wouldn't go below 24" radius in HO.

Then its a matter of how much space you need between levels and the resulting grade. On my layout, since I'm modeling 1900-1905, and using small steam engines, I had to keep the grade low, therefore I went to 27" radius and only three inches between levels (2 3/8" of clear space) because I'm not running double stacks or auto racks. If you are running modern equipment, with 19" radius and 4" between levels, that's 3.3% grade. The length of one turn = 2 x radius x 3.14, then divide the separation between levels by the length of a turn and multiply by 100 to get the grade. 19" x 2 = 38" x 3.14 = 119, 4/119 = 0.033 x 100 = 3.3

You also have to take into account there will be a vertical curve at the top and bottom of the grade to get the slope to flat.

A helix doesn't have to be completely hidden. You can bulge a turn or two out from the helix structure to create a visible scene in the middle of the helix. I also visited a club that had a large diameter helix (36" radius?) at the end of a peninsula. It was designed so the turns were little shelves with a back drop behind them and totally visible for about 3/4 of the turn. The tracks were ballasted and the backdrop painted with sky and tree line. You could easily watch your train run up or down the helix.

Here is the base for the helix. I use a base so I have a level place to start building from.

I then cut a series of stepped blocks to establish the grade. They are glued to the base.

Each turn is applied by screwing the roadbed arcs to the blocks, track is laid as I go. I use 1/2" #6 pan head screws on the track centerline to screw the track to the roadbed. If I later need to adjust or remove track I can unscrew or loosen the screws and then tighten them back up again. Once the track is in place I glue spacer blocks to the outside of the roadbed. Then the next layer of roadbed is applied and screwed to the spacer blocks. I make the roadbed joints fall on the spacer blocks so they become the splice blocks for each turn.

Finally I use risers to lift the base and the whole helix up to the final height. You might also notice I added that "extra" turn to the outside of the helix getting the inside turn to the outside.

A helix has four design components, the radius, the spacing between turns, the grade and the total rise. It has to be designed to take all three of those into account. The first two determine the grade. Personally I wouldn't go below 24" radius in HO.

Then its a matter of how much space you need between levels and the resulting grade. On my layout, since I'm modeling 1900-1905, and using small steam engines, I had to keep the grade low, therefore I went to 27" radius and only three inches between levels (2 3/8" of clear space) because I'm not running double stacks or auto racks. If you are running modern equipment, with 19" radius and 4" between levels, that's 3.3% grade. The length of one turn = 2 x radius x 3.14, then divide the separation between levels by the length of a turn and multiply by 100 to get the grade. 19" x 2 = 38" x 3.14 = 119, 4/119 = 0.033 x 100 = 3.3

You also have to take into account there will be a vertical curve at the top and bottom of the grade to get the slope to flat.

A helix doesn't have to be completely hidden. You can bulge a turn or two out from the helix structure to create a visible scene in the middle of the helix. I also visited a club that had a large diameter helix (36" radius?) at the end of a peninsula. It was designed so the turns were little shelves with a back drop behind them and totally visible for about 3/4 of the turn. The tracks were ballasted and the backdrop painted with sky and tree line. You could easily watch your train run up or down the helix.

GeeTee , you state that yours is a 30 inch radius , what is the grade ? Thanks for the pictures . how does it work?

Dave , what is the radius and grade for the one in your photo's ? Thank you also for the pictures . How does your helix work in terms of operations problems?

Let me ask this question then . Is the radius as important as the grade or is the grade the governing factor? Obviously I would not want to build a fifteen inch radius , but if the radius is compatible with my equipment then the grade would become the governing factor to make sure there were no operation problems , correct ?

Dave , what is the radius and grade for the one in your photo's ? Thank you also for the pictures . How does your helix work in terms of operations problems?

Let me ask this question then . Is the radius as important as the grade or is the grade the governing factor? Obviously I would not want to build a fifteen inch radius , but if the radius is compatible with my equipment then the grade would become the governing factor to make sure there were no operation problems , correct ?

GeeTee

Well-Known Member

1.5% weighted single F7 s 15 - 20+ cars weighed E units 20-30 cars . I have seen some with 2.5-2.8% grades and it was difficult to get a switcher to pull more than 2-3 cars up it.

The grade determines how many cars you can move for a given engine. For any curve ,tightening the radius causes the forces in train to go up .

Most people end up with the steepest grades and the worst track work ( they think it wont be noticed) in the helix, which results in the highest stresses in train. Thats a recipe for random uncouplings , derailments ,and stalling . Problems don't seem to happen more often in the helix , they do happen more often. if you want to keep problems out of the helix,grades should be the same or less in the helix and the quality of track work should be the highest .

26 -24 " radius yields a 1.8 -2% grade. If your grades and curves on the rest of the layout are less, then the stress in the train will be highest in the helix and thats the most likely place to have issues.

A lot of people think they can solve their problems by slapping helpers on the front end , while that does increase the pulling power it does nothing for relieving the stress in train . And I've never had much luck running mid or end of train helpers all it takes is a momentary drop in power and couplers get ripped out or a derailment occurs.

The grade determines how many cars you can move for a given engine. For any curve ,tightening the radius causes the forces in train to go up .

Most people end up with the steepest grades and the worst track work ( they think it wont be noticed) in the helix, which results in the highest stresses in train. Thats a recipe for random uncouplings , derailments ,and stalling . Problems don't seem to happen more often in the helix , they do happen more often. if you want to keep problems out of the helix,grades should be the same or less in the helix and the quality of track work should be the highest .

26 -24 " radius yields a 1.8 -2% grade. If your grades and curves on the rest of the layout are less, then the stress in the train will be highest in the helix and thats the most likely place to have issues.

A lot of people think they can solve their problems by slapping helpers on the front end , while that does increase the pulling power it does nothing for relieving the stress in train . And I've never had much luck running mid or end of train helpers all it takes is a momentary drop in power and couplers get ripped out or a derailment occurs.

So if I were to put straight sections inbetween the curves , that would allow me to lessen my grade but still keep the peninsula more narrow , correct? It will need to be a double track and I am thinking a 24 inch inside curve ( 1.51% ) and a 27 inch outside curve ( 1.38% ) with a 24 inch straight between curves. That should provide for trouble free operation if the trackwork is good shouldnt it ?

GeeTee

Well-Known Member

It sounds like a good place to start , I would build the first couple of levels and run a train up and then back it down , lightest cars at the head , heavy on the tail and see how it does , turn the whole train around and back or push it up the helix , check clearances on the inside if your going to run passenger cars. Rail head to the bottom of the sub bed should be at least 2 5/8 , 2 7/8 to 3" would be better .So if I were to put straight sections inbetween the curves , that would allow me to lessen my grade but still keep the peninsula more narrow , correct? It will need to be a double track and I am thinking a 24 inch inside curve ( 1.51% ) and a 27 inch outside curve ( 1.38% ) with a 24 inch straight between curves. That should provide for trouble free operation if the trackwork is good shouldnt it ?

What are you going to use for motive power ? steam? diesel?

santafewillie

Same Ol' Buzzard

Along with grade and minimum radius, make sure that you can fit inside your helix.

The radius is about 27" and the grade works out to 1.8% roughly. I only have 3" separation between turns because I model 1900-1905 and don't have high equipment. But I have small engines. The goal was to be able to haul 4 car passenger trains and 8-10 car freights on the grade with an MDC 2-8-0, and I can do that.