CanuckMark

Member

Hi guys!

Well, the second main is on line so I think the layout is at a point where I can show 'er off.

The history is as follows: As a kid (youngest of three) I was the one who got "dragged" to the NMRA conventions in the late 70s and early 80s. My dad was a master modeller and did some pretty cool stuff back then - mostly logging short run stuff with Shays and narrow gauge as his faves. I actually remember driving a switcher at a Domtar plant somewhere in western ontario or eastern Michigan. I did a few decent models on my own too. Then I lost interest in my teenage years.

My dad passed away in July and it was a weird feeling sitting in his old layout room. Something said "you gotta do this again" (and trust me, it wasn't my wife). So the journey began...

A dual main with a switching yard and turntable on the left side, a blank canvas for the right. The outer main is about 63 feet long. I think the framework is pretty overkill but it sure is sturdy. Went with code 83 right from the start - the LHS actually sells it cheaper than code 100.

Went with code 83 right from the start - the LHS actually sells it cheaper than code 100.

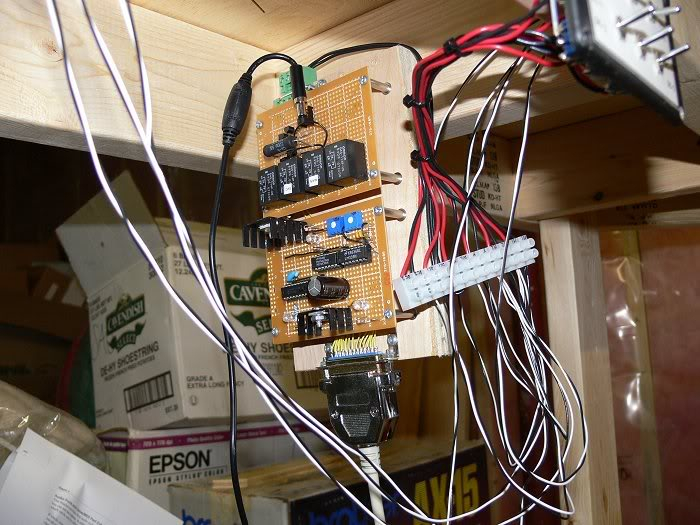

I decided I wanted the flexibility of DC and DCC, so each main and the yard are separately switched for either. So far this has worked really well.

Decided to go "scratch" with DCC and built the TMW system (search TMW DCC on the web). The controller is a Pentium I 233 connected via parallel to a PIC based microcontroller. This system works amazing.

cont...

Well, the second main is on line so I think the layout is at a point where I can show 'er off.

The history is as follows: As a kid (youngest of three) I was the one who got "dragged" to the NMRA conventions in the late 70s and early 80s. My dad was a master modeller and did some pretty cool stuff back then - mostly logging short run stuff with Shays and narrow gauge as his faves. I actually remember driving a switcher at a Domtar plant somewhere in western ontario or eastern Michigan. I did a few decent models on my own too. Then I lost interest in my teenage years.

My dad passed away in July and it was a weird feeling sitting in his old layout room. Something said "you gotta do this again" (and trust me, it wasn't my wife). So the journey began...

A dual main with a switching yard and turntable on the left side, a blank canvas for the right. The outer main is about 63 feet long. I think the framework is pretty overkill but it sure is sturdy.

I decided I wanted the flexibility of DC and DCC, so each main and the yard are separately switched for either. So far this has worked really well.

Decided to go "scratch" with DCC and built the TMW system (search TMW DCC on the web). The controller is a Pentium I 233 connected via parallel to a PIC based microcontroller. This system works amazing.

cont...

Last edited by a moderator: