tankist

Active Member

having track planning software its nice and all but it still doesn't give the exact feeling of the outcome. so after several attempts with anyrail i decided to just get down there and doodle around with actual track. spent several hours and my mind is boiling - i think i officially hit the over planning faze.

so if you feel like, take a look and leave your 0.02$ or 1M$ worth. rip this to shreds if you feel so, ideas and suggestions are welcome.

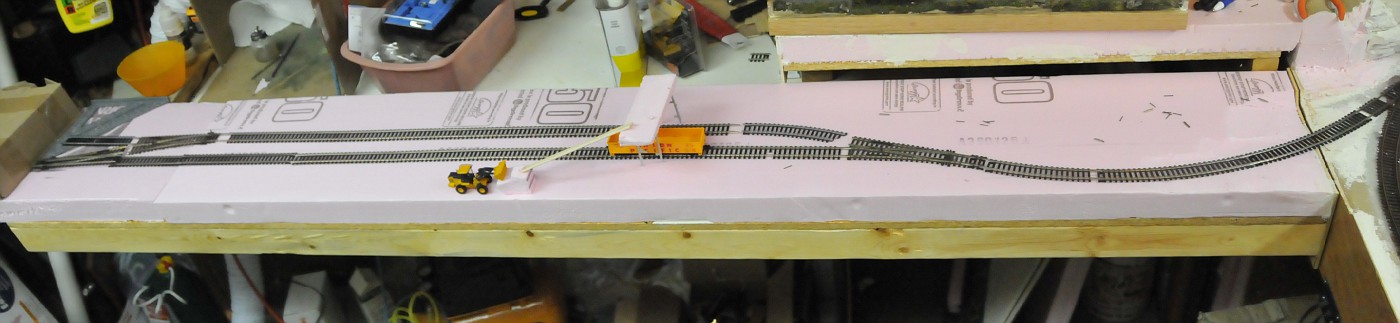

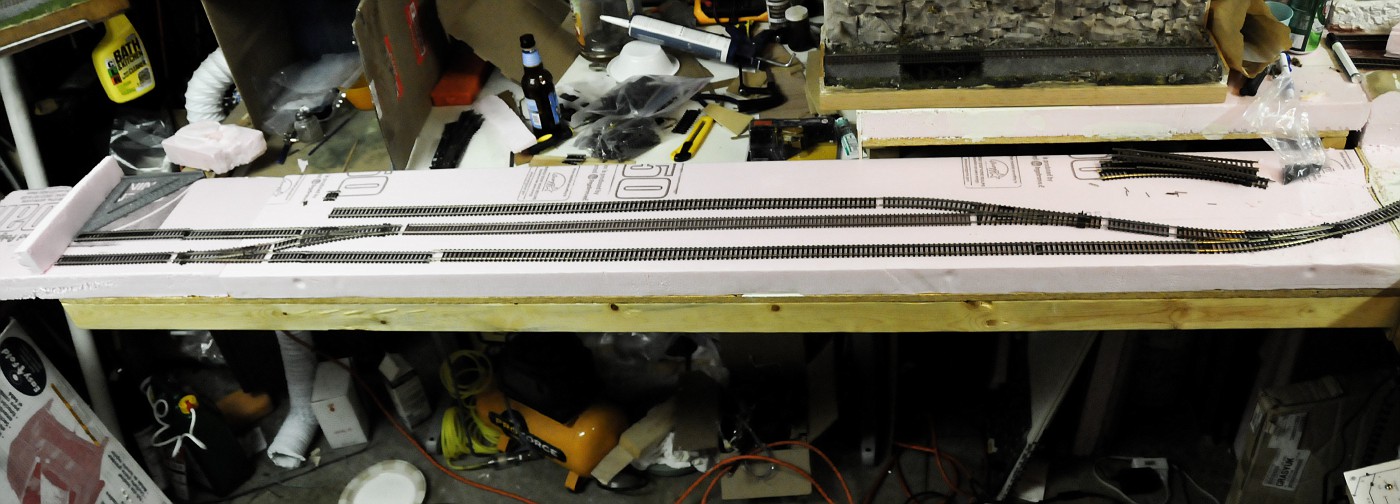

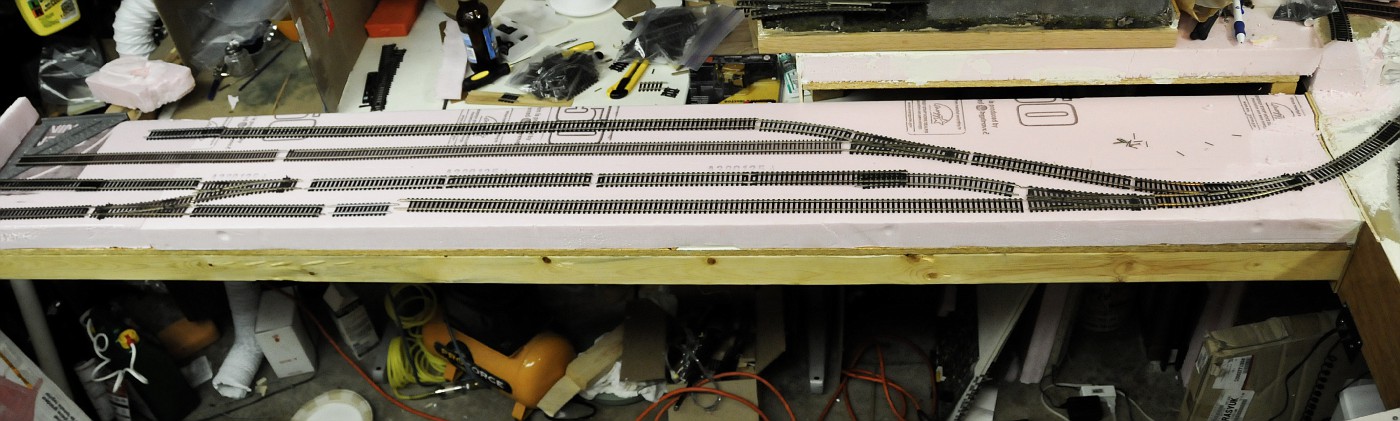

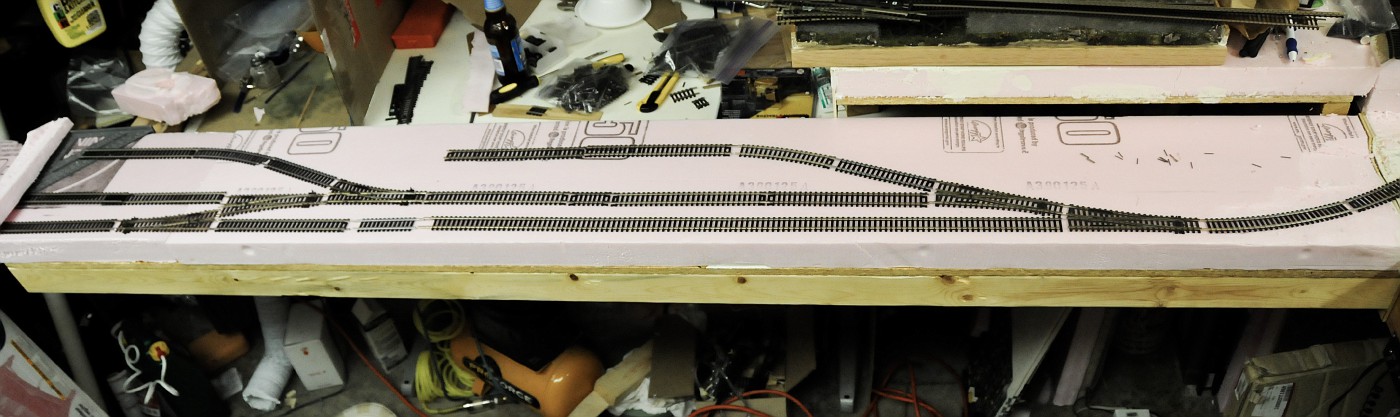

below is the main 4x7 of my layout. notice a turnout under the bridge in lower left corner. diverging path completes the curve, while the straight through leads to the module - a 11 inches by 7 feet long (can be partially seen here). additional length (~2 feet) can be added for transfer table or temp addition but main lenght dimension is limited by the storage place for this module.

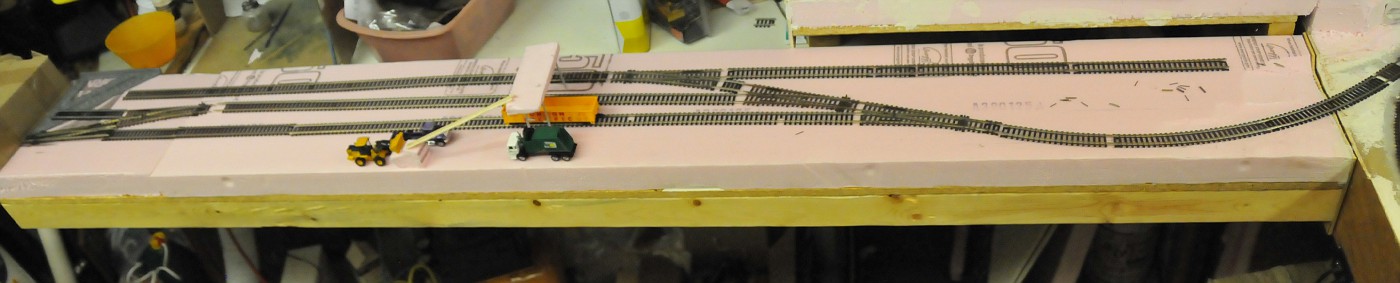

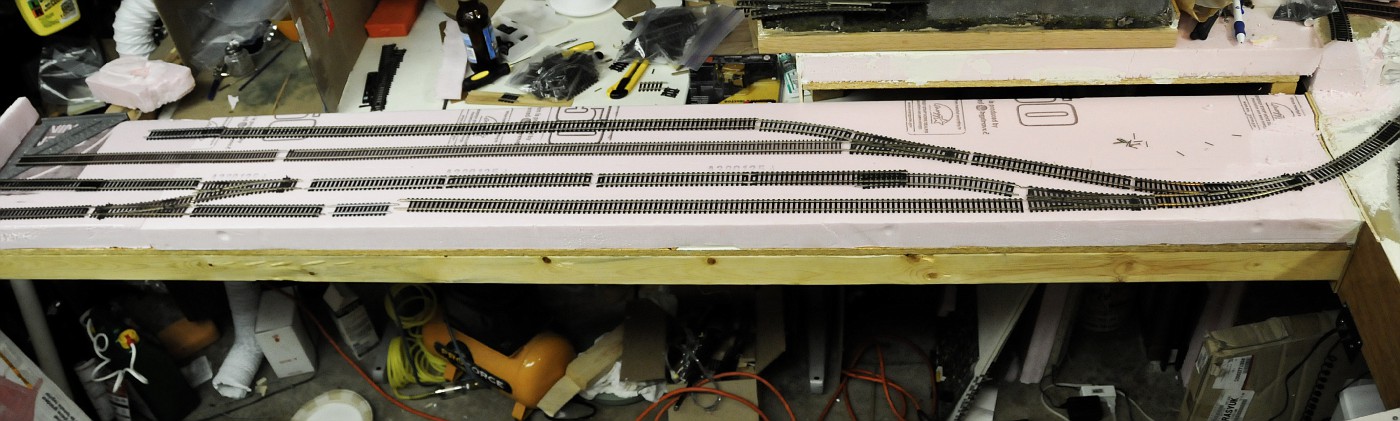

current operation idea of the module is a pier for barges loading and unloading coal, sand, limestone to service a cement plant (and perhaps grain and gravel). and perhaps have industry or 2 in the backside (either cut off front or even simply drawn) loading boxcars and/or tank cars. here is what i came up , notes of operation are included as i see it.

lowest/closes line is where goods are loaded to/from the barge. long enough to clear 6 bethgons or 8 acf-2970 covered hoppers (verified). engine can leave via runaround (even without extension). stub at the end of runaround track also serves an industry. 3rd track serving other building/buildings s but can be omitted. notice the very first turnout is a curved one (peco setrack) to maximise which was verified workable by even dash8 engine (after all it is a low speed zone).

main wekness is short lead after the curved turnout. switcher will need to foul the main when disconnecting cars from the back of train and shoving into stab and spur.

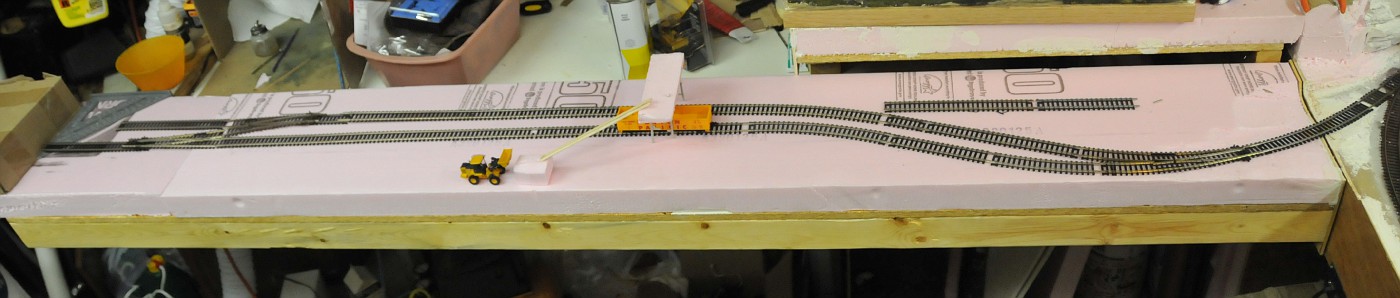

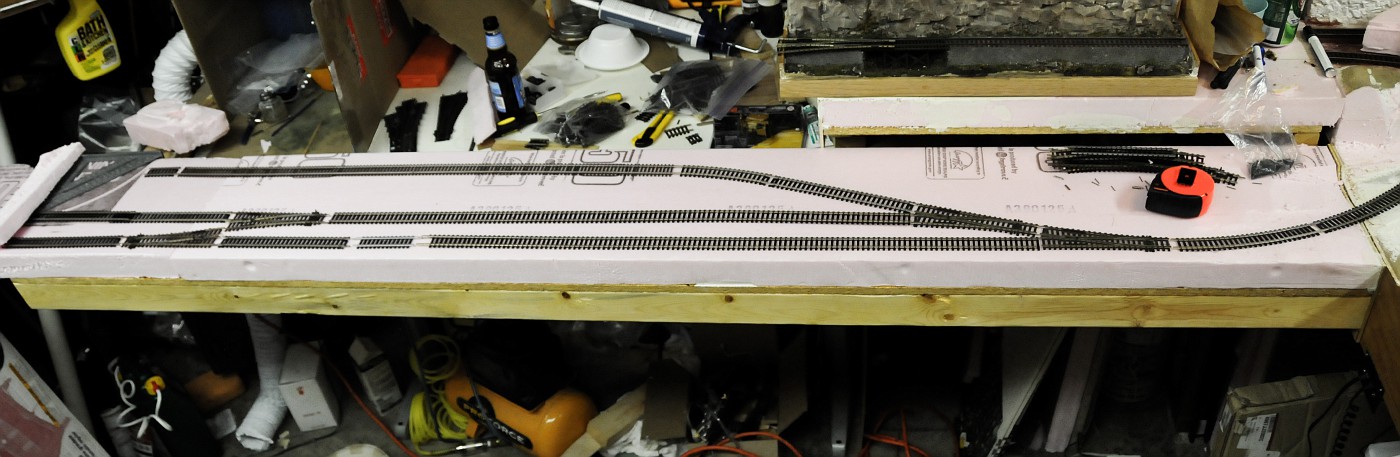

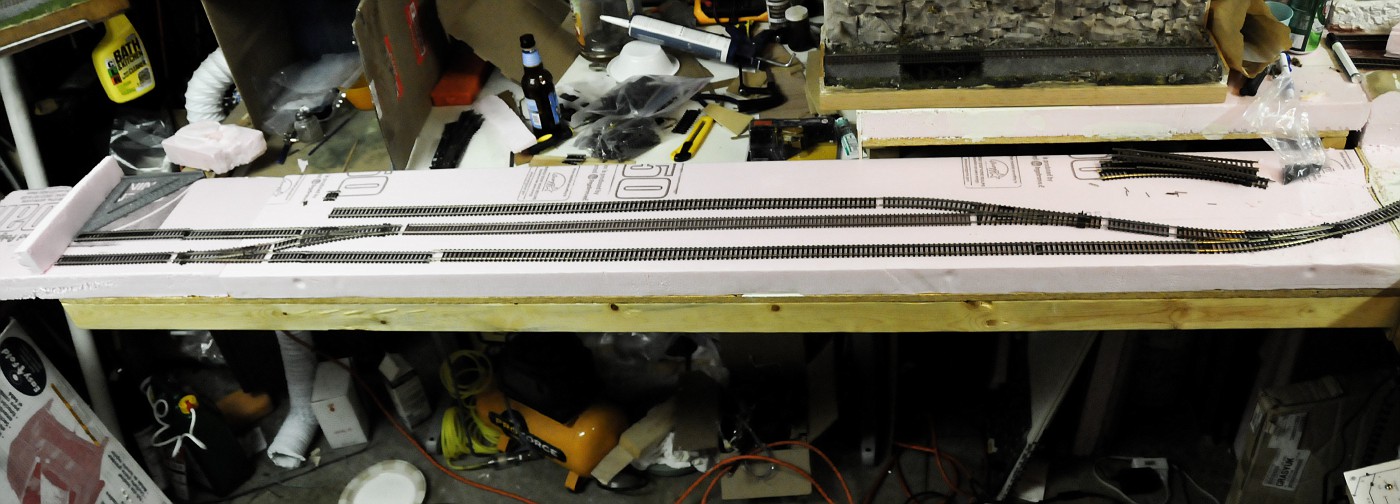

pretty much same thing but with ordinary turnout. cars specified above still fit will need to be positioned precisley to clear the turnouts of runaround. lead seems to be sufficient to work one car.

-------------

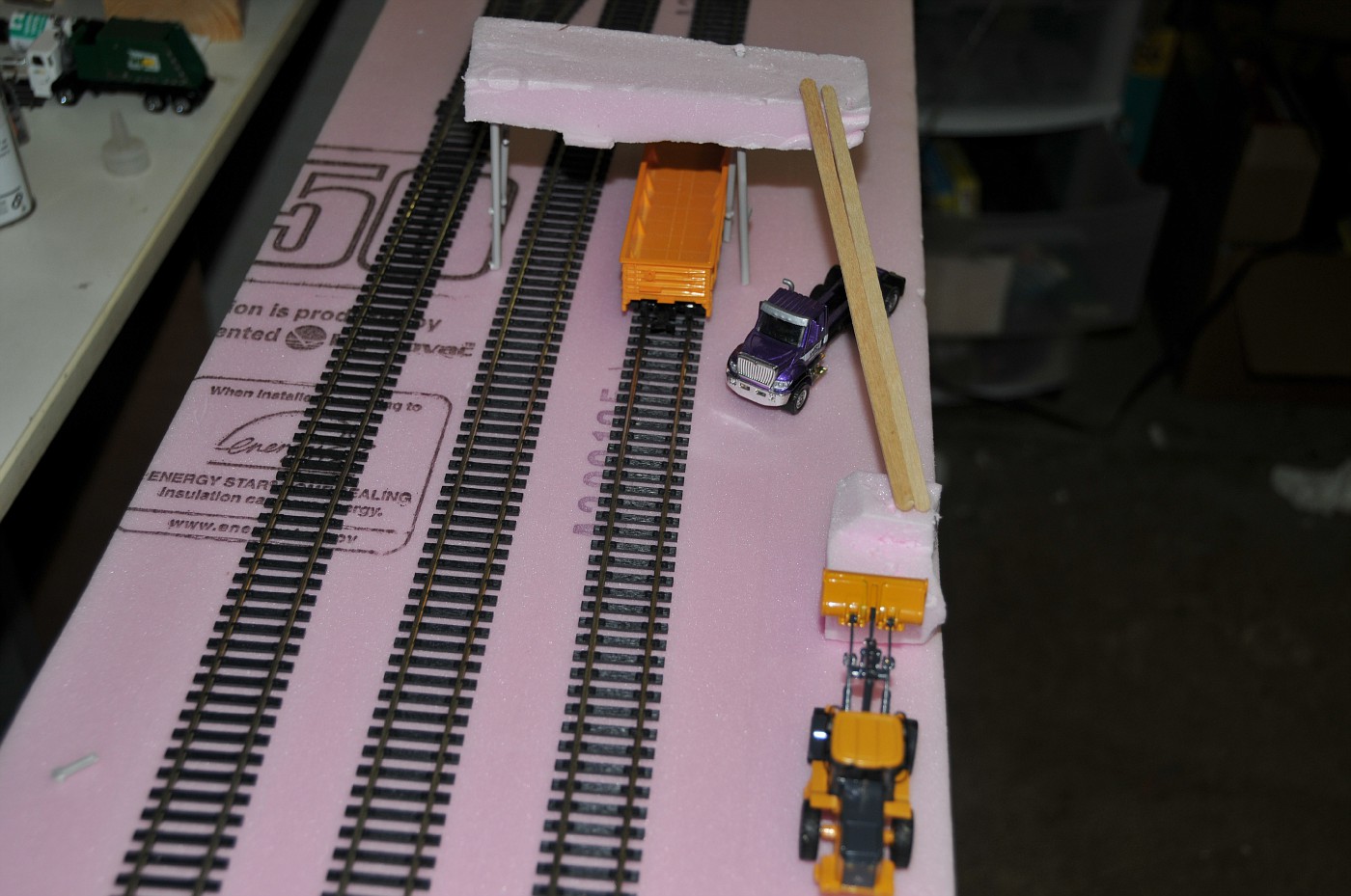

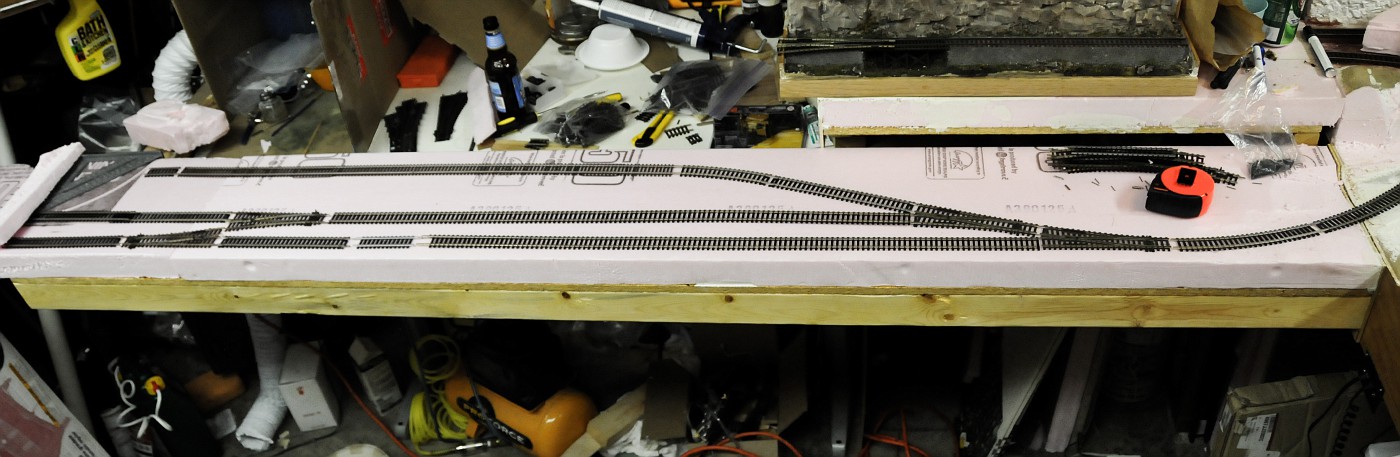

from this point, while i'm at it i'm trying out crazy ideas (and that's where i go bananas)...

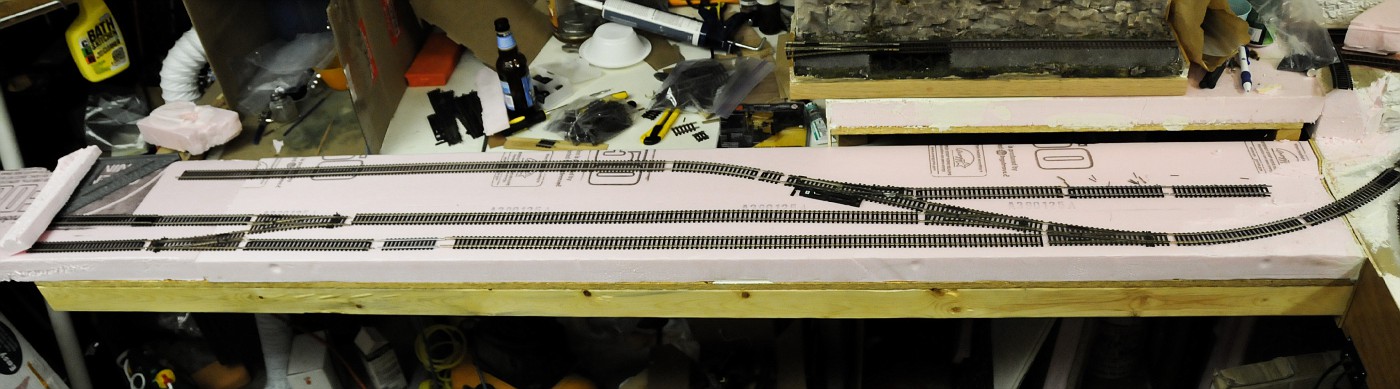

additional spur as a switch back. i now realize it is unreachable unless switcher brings one car into the module head in.

2 spurs plain.

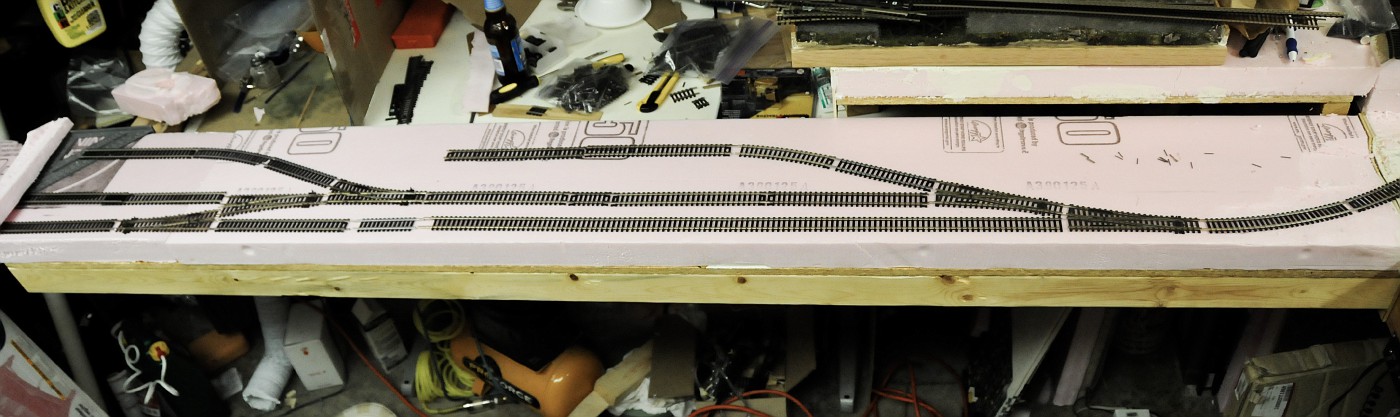

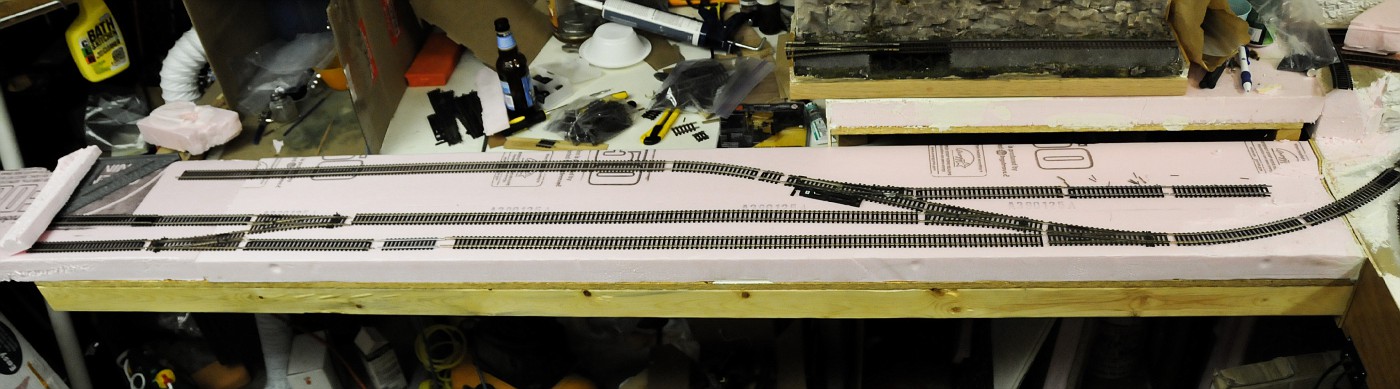

2 spurs with a switch back. i do realise it is unreachable if the non switchback portion is occupied, but if it is made long enough to hold switcher and 2 cars this can be a puzzle. a wacky one.

and apotheosis of the evening is this crazy contraption. 4 track quasy yard

welcome to discuss.

(3 oclock! the kid gets up in 3 hours

the kid gets up in 3 hours  )

)

so if you feel like, take a look and leave your 0.02$ or 1M$ worth. rip this to shreds if you feel so, ideas and suggestions are welcome.

below is the main 4x7 of my layout. notice a turnout under the bridge in lower left corner. diverging path completes the curve, while the straight through leads to the module - a 11 inches by 7 feet long (can be partially seen here). additional length (~2 feet) can be added for transfer table or temp addition but main lenght dimension is limited by the storage place for this module.

current operation idea of the module is a pier for barges loading and unloading coal, sand, limestone to service a cement plant (and perhaps grain and gravel). and perhaps have industry or 2 in the backside (either cut off front or even simply drawn) loading boxcars and/or tank cars. here is what i came up , notes of operation are included as i see it.

lowest/closes line is where goods are loaded to/from the barge. long enough to clear 6 bethgons or 8 acf-2970 covered hoppers (verified). engine can leave via runaround (even without extension). stub at the end of runaround track also serves an industry. 3rd track serving other building/buildings s but can be omitted. notice the very first turnout is a curved one (peco setrack) to maximise which was verified workable by even dash8 engine (after all it is a low speed zone).

main wekness is short lead after the curved turnout. switcher will need to foul the main when disconnecting cars from the back of train and shoving into stab and spur.

pretty much same thing but with ordinary turnout. cars specified above still fit will need to be positioned precisley to clear the turnouts of runaround. lead seems to be sufficient to work one car.

-------------

from this point, while i'm at it i'm trying out crazy ideas (and that's where i go bananas)...

additional spur as a switch back. i now realize it is unreachable unless switcher brings one car into the module head in.

2 spurs plain.

2 spurs with a switch back. i do realise it is unreachable if the non switchback portion is occupied, but if it is made long enough to hold switcher and 2 cars this can be a puzzle. a wacky one.

and apotheosis of the evening is this crazy contraption. 4 track quasy yard

welcome to discuss.

(3 oclock!