KriegslokBR52

Well-Known Member

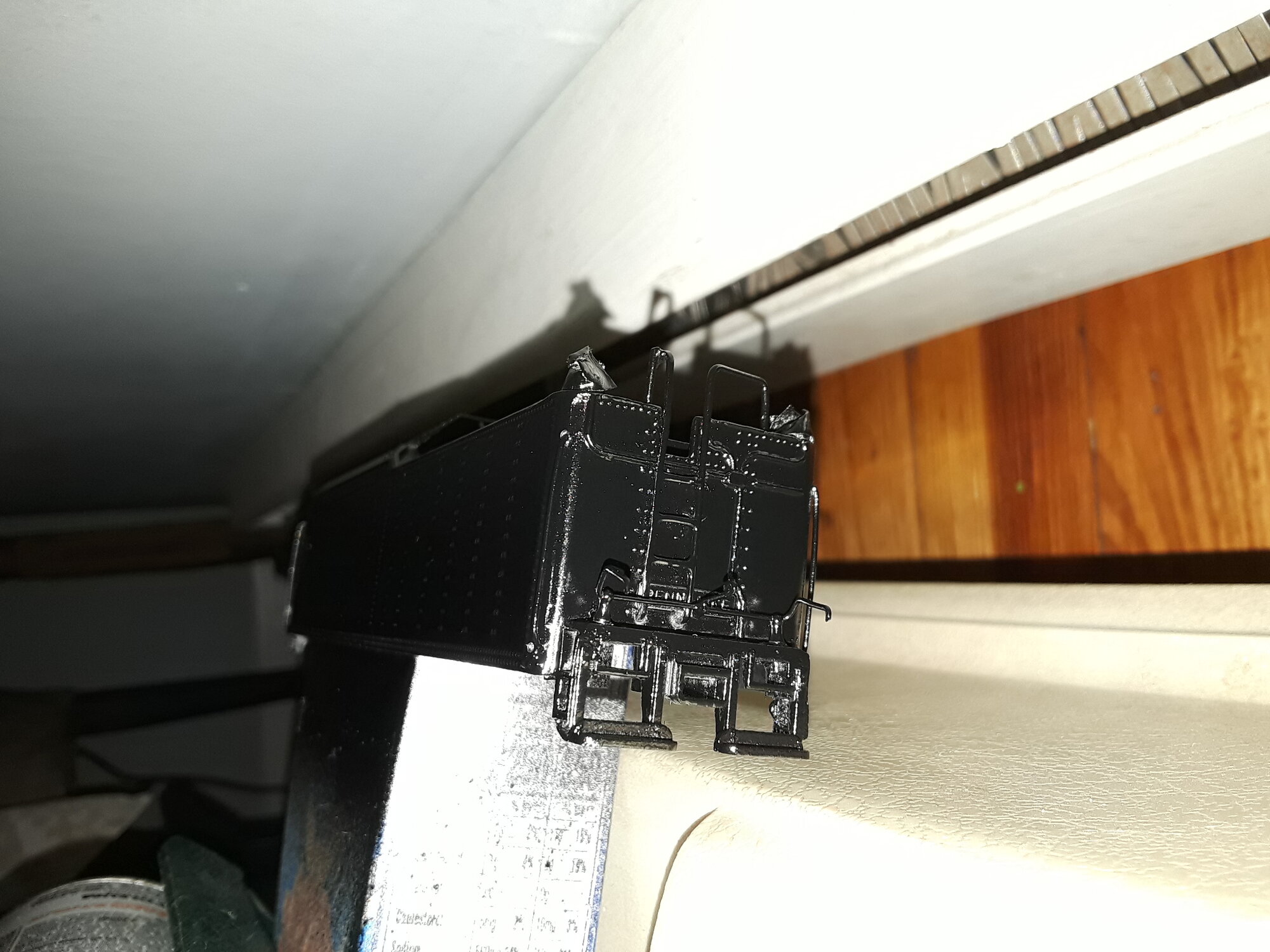

Today working on detailing the tender shell. Missing was the rear coal bin diagonal slide, this one i just cut from a sheet of brass, used the existing tiny screws to secure it in place and redid the ladder going from top of water reservior to top of that slide. Next was the plugging of that hole in the rear bulkhead from light, as these tenders did not have them. After the bulkhead had to redo that rear ladder which was used by the breakman to get to doghouse on top of the tender.

After that a quick wash again from my greasy hands and used automotive gray rustoleum to prep it for black paint. Here it's warming again by the heater before satin black spray.

Pennsy fans when they hear that i did not use Brunswick green will probably scream in horror. That's ok, it's war time right now on my layout and boys on the Eastern front need the green. Besides these hard working machines were extremely dusty when working and i will weather this one heavily just like its scale 1:1 brethren.

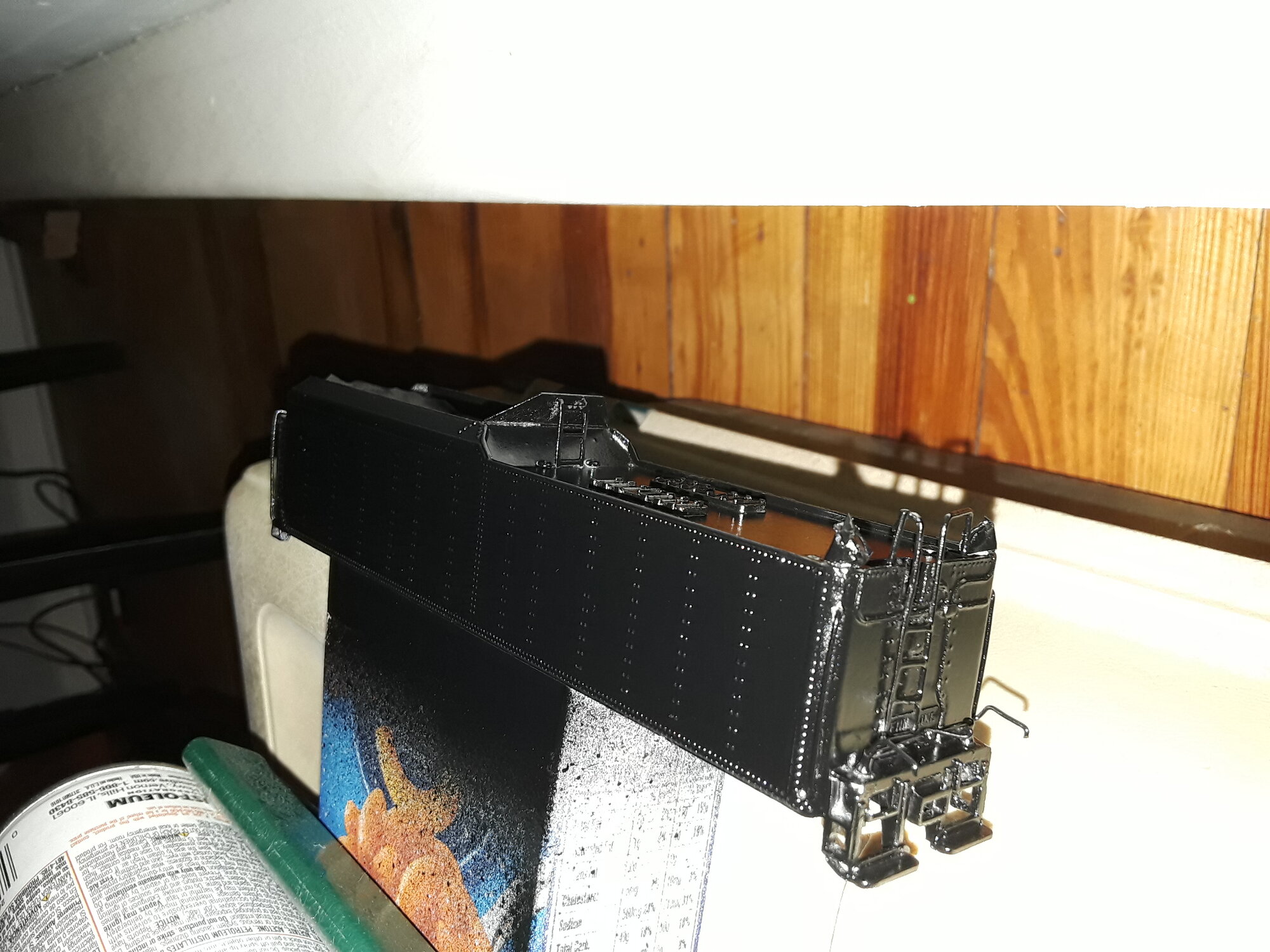

Lastly here in Satin black automotive spray, slowly "baking" it over the heater:

After that a quick wash again from my greasy hands and used automotive gray rustoleum to prep it for black paint. Here it's warming again by the heater before satin black spray.

Pennsy fans when they hear that i did not use Brunswick green will probably scream in horror. That's ok, it's war time right now on my layout and boys on the Eastern front need the green. Besides these hard working machines were extremely dusty when working and i will weather this one heavily just like its scale 1:1 brethren.

Lastly here in Satin black automotive spray, slowly "baking" it over the heater:

Last edited: