KriegslokBR52

Well-Known Member

Just starting a new thread. My main areas of interest are polish locomotives and rolling stock, as well as american. So my modeling is pretty varried. My american specialty are the many electric locomotive models, especially those which we will not see anymore in service and my personal favorite subject are Conrail electric operations and its predecessors; Penn Central and Pennsy. Long time ago i have built a few E33 locomotives, since the only available models at the time were brass models (way beyond my budget):

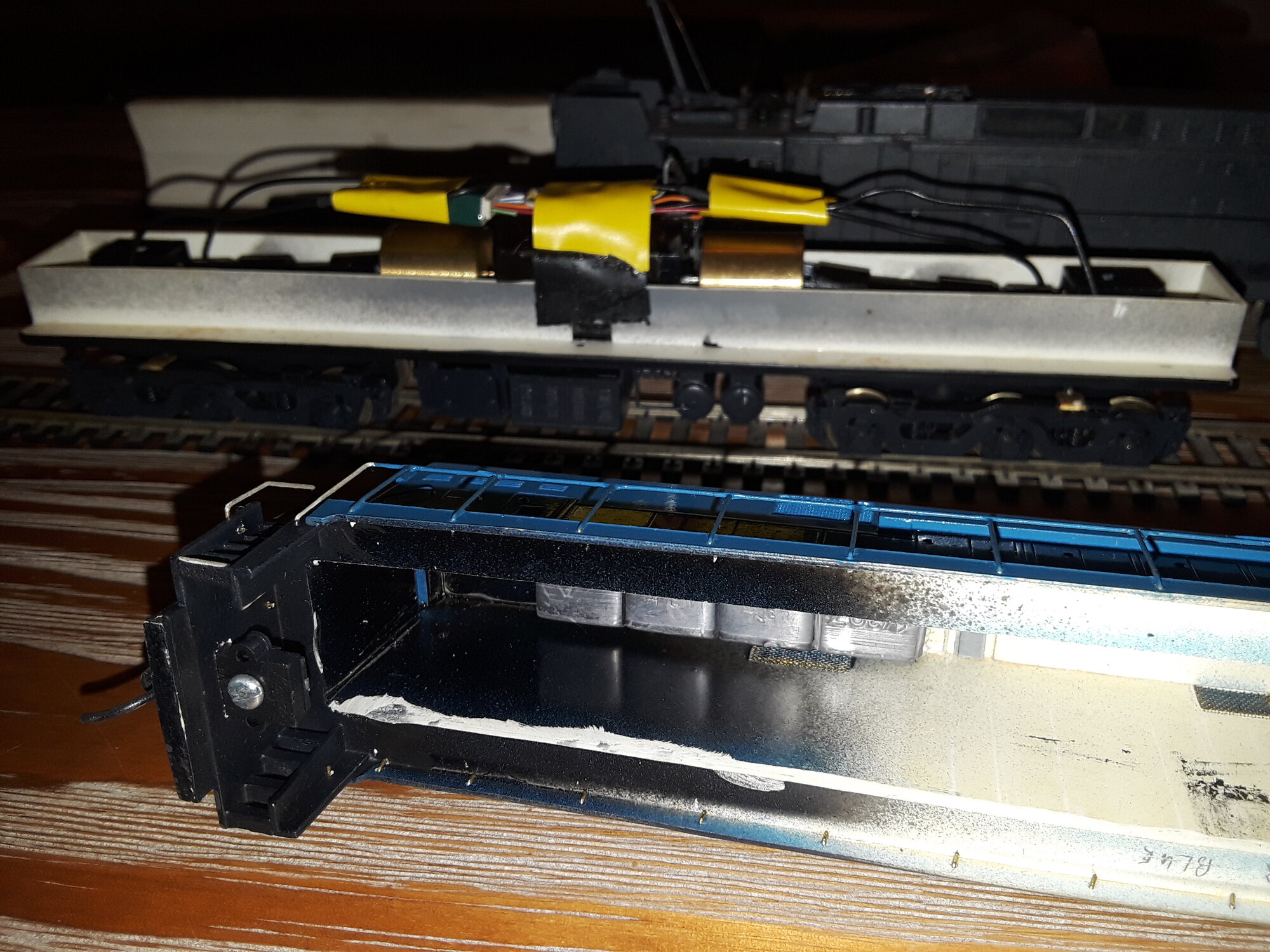

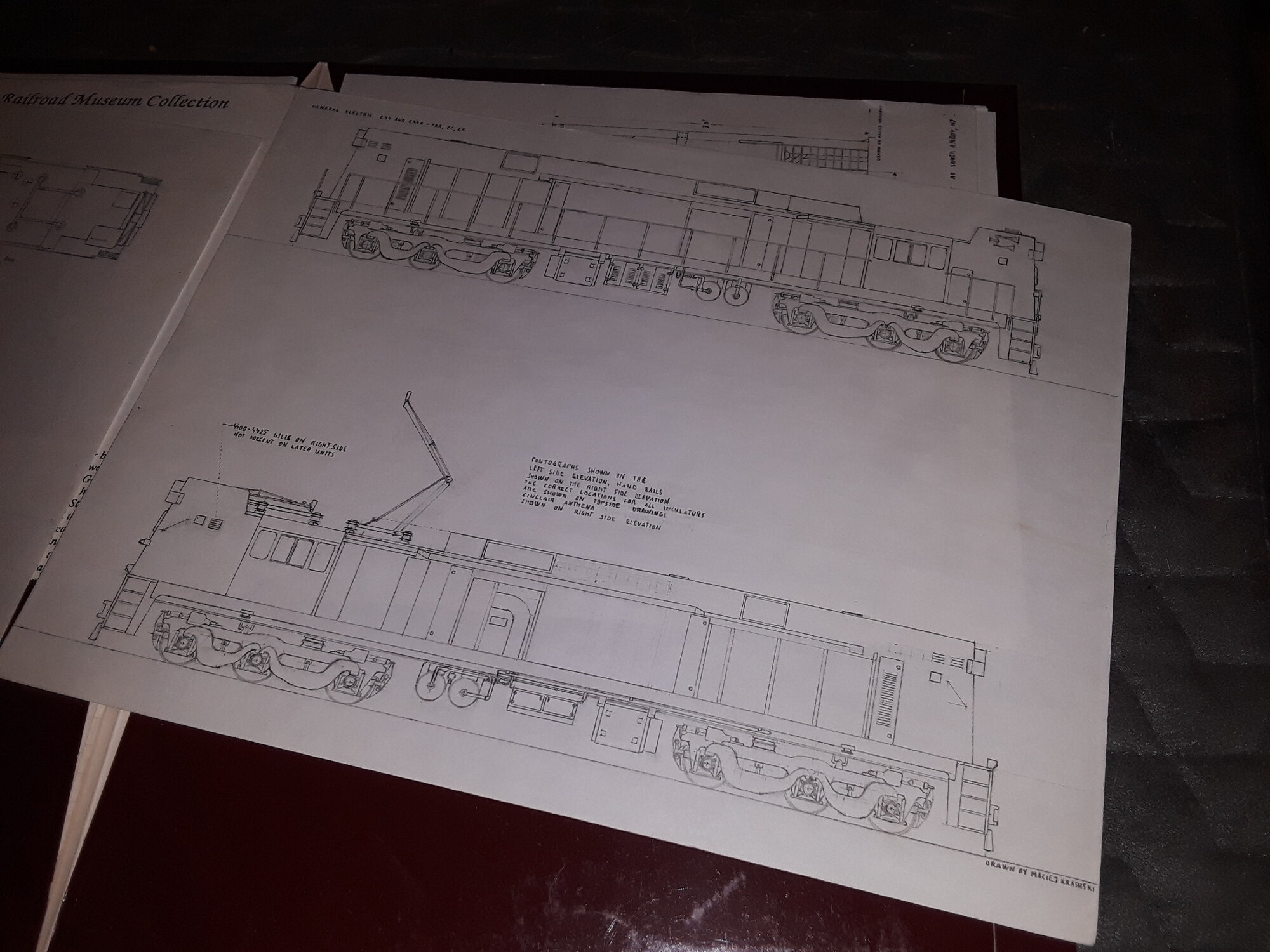

After E33 came E44. Here was the problem, there are no scale drawings available. Based on drawings of E33 taken from "Shore Line" 1980 issue and armed with a pencil, measuring tape, and notebook and with the blessing of Railroad Museum of Pennsylvania curator, i was able to crawl all over the only survivor of the clan: E44-4465. After a weekend of measuring and note taking i've had my very own E44 drawings:

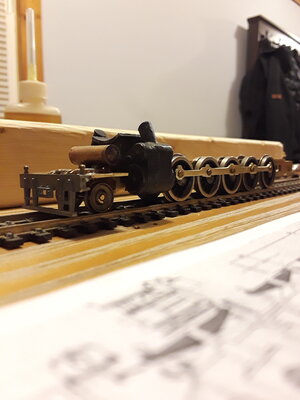

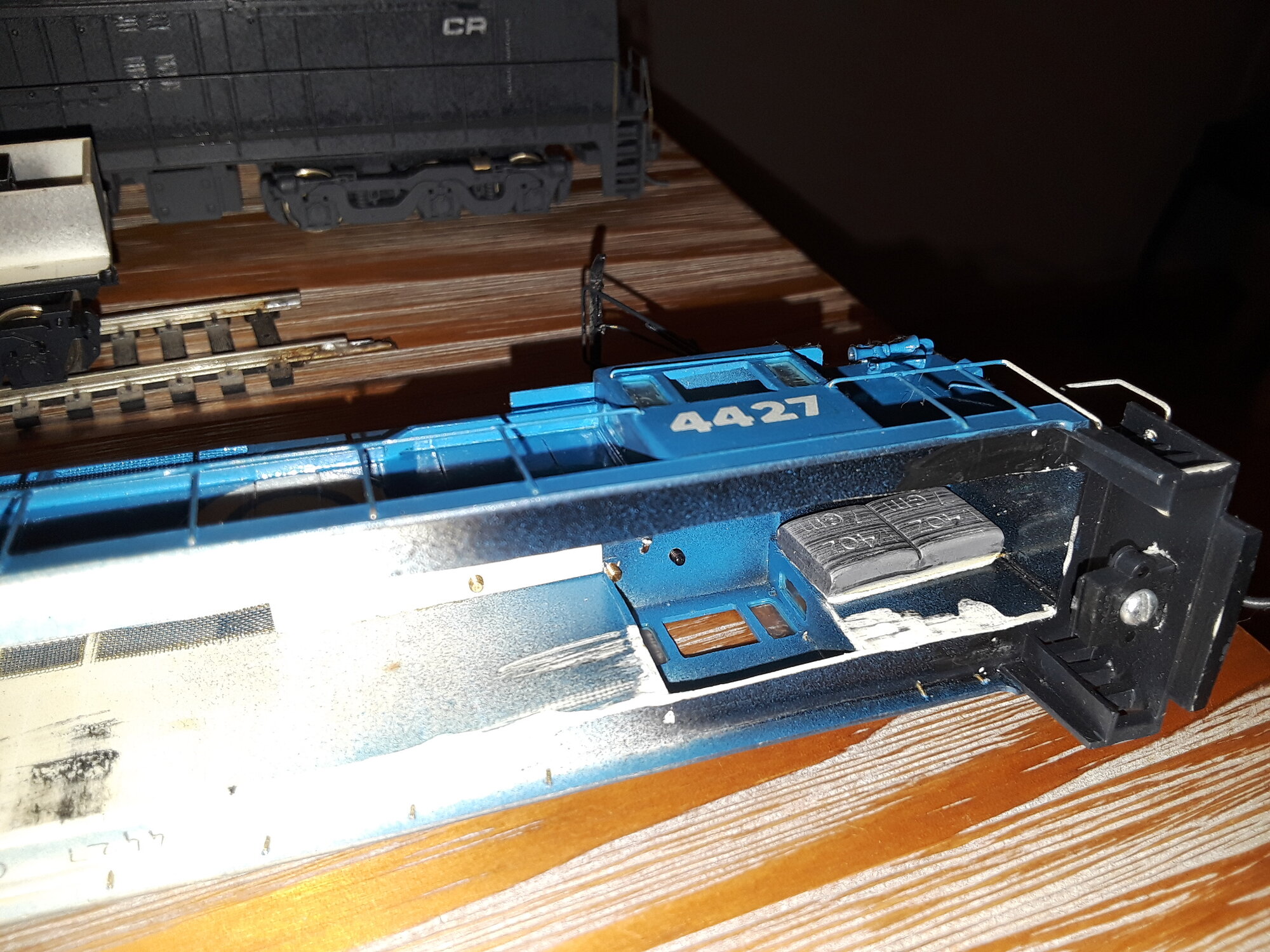

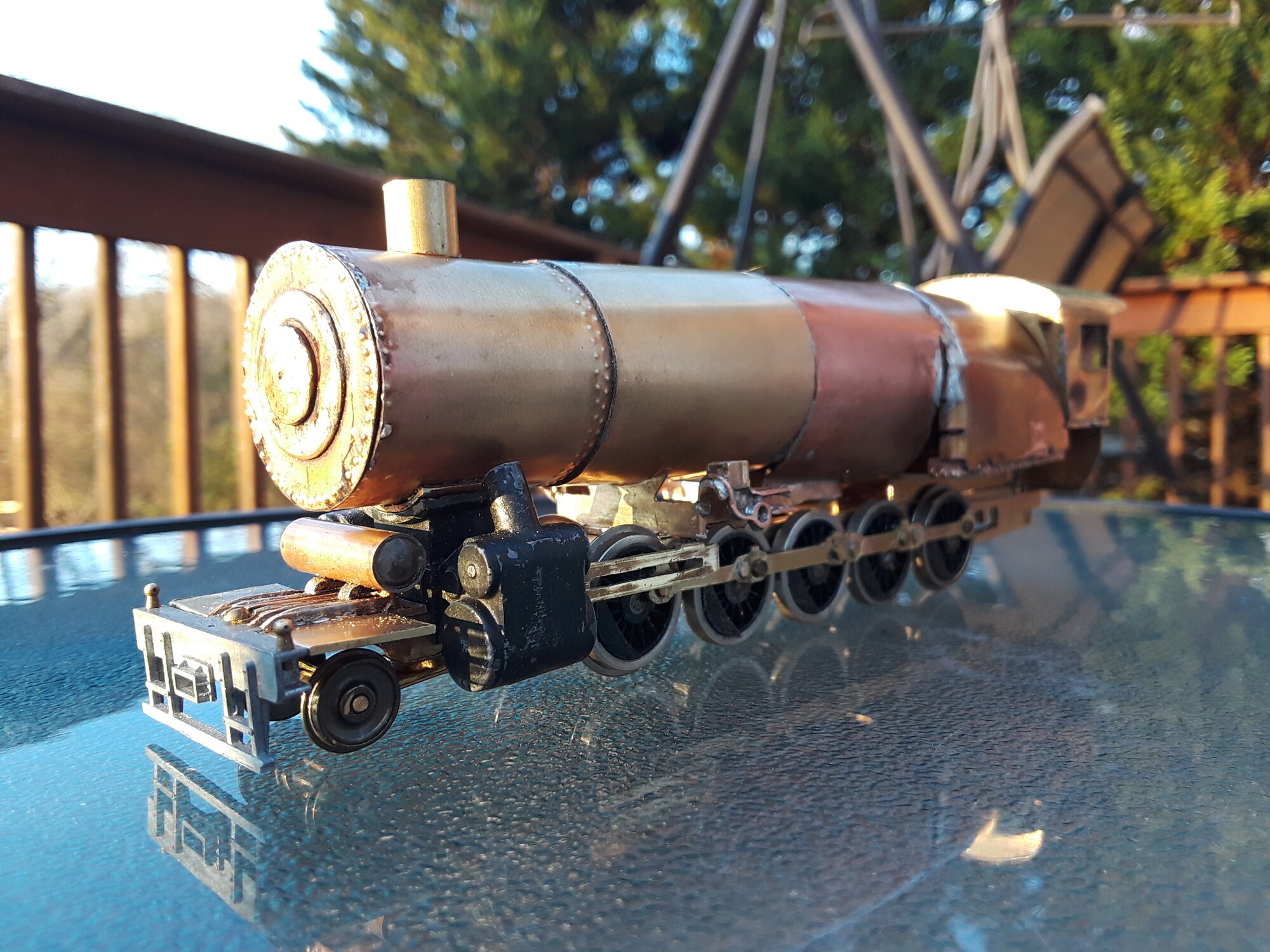

Out came 4427 in Conrail dress blues and 4431 in interim PC black with CR stensils. I am a steam nut at heart, always will be, so project started few months ago is a Lehigh & New England F1 decapod:

It took several months researching this locomotive and finding plans for it. Found plans for almost identical I2 Western Maryland, and that is my main refference. More on that later.

After E33 came E44. Here was the problem, there are no scale drawings available. Based on drawings of E33 taken from "Shore Line" 1980 issue and armed with a pencil, measuring tape, and notebook and with the blessing of Railroad Museum of Pennsylvania curator, i was able to crawl all over the only survivor of the clan: E44-4465. After a weekend of measuring and note taking i've had my very own E44 drawings:

Out came 4427 in Conrail dress blues and 4431 in interim PC black with CR stensils. I am a steam nut at heart, always will be, so project started few months ago is a Lehigh & New England F1 decapod:

It took several months researching this locomotive and finding plans for it. Found plans for almost identical I2 Western Maryland, and that is my main refference. More on that later.