ModelRailroadForums.com is a free

Model Railroad Discussion Forum and

photo gallery. We cover all scales and sizes of model railroads. Online since 2002, it's one of the oldest and largest model railroad forums on the web. Whether you're a master model railroader or just getting started, you'll find something of interest here.

Some of the switches on the layout I bought last year are Atlas Snap switches, which I know are not the best quality.

One of them is giving me a problem where if any locomotives are run through the switch in one direction it causes a short and my DCC controller goes into SVDA mode and had to be reset, the controller is a MRC Prodigy Express. If I run locomotives the other direction they do just fine.

I'm curious if there is a better replacement option? I know #4 turnouts are not the same curve radius, and changing the curve radius in this location on the layout would be a major undertaking.

If not, any suggestions on what I might do to fix the problem on this switch? I can't see any visible problems that might be causing this.

There are no quality, direct replacements for Atlas snap switches. The geometry is different for almost all manufacturers.

The rework shouldn't be too bad, but to know for certain, you will have tor order a replacement and compare. Hopefully you have been thinking about Peco turnouts, and if so, there are HO scale templates you can download and print at scale size to see how much rework is going to be needed.

Sometimes they short right at the frog when the back of the wheel on one rail touches the other rail. Make sure the wheels and track are in gauge and if they are, some clear nail polish or other lacquer applied to the rails at the spot where they short will fix it.

I have Atlas switches I got in the 1980's still going strong.

Quality in regards to Atlas switches is in their detailing, not their mechanical properties. There are replacements, but none are as good as the quality of an Atlas. Toy train sets from Bachmann, Tyco and other manufacturers have ones that follow the same geometry. The clear nail polish is a useful solution to shorting, but something else is wrong if they don't work. Check out the suggestions that Paul posted regarding track and wheel gauge.

What are the locomotives that short? Is it your new Big Boy? The 4 coupled driver sets will most like short on the diverging route. The corner is just too sharp.

The new Big Boy yes but other locomotives are doing the same thing that used to work just fine. I haven't tested every single locomotive I have but I know an BLI SD40-2, and a couple of different GP units. All work fine going one direction, all almost always cause shorts going the other direction.

Which way are they going and on which route are they shorting? What brand GPs are you running? GPs should be fine and my current setup has one that Athearn SD60s run through fine. Could you post a photo of the switch?

Back when I was running MRC, I had a couple of snap switches that would constantly give me the same issue you describe above. The nail polish trick helped, but only a little. It was a constant struggle. What finally "fixed" the issue in the end, for me, was installing a booster with a built in circuit breaker (Tams Valley). This took the tiny hit instead of the MRC unit and things improved dramatically.

Fast forward a number of year and I am now running RailPro and have recently put one of the old offending switches back into play. The same issue is popping back up. I still have my nail polish. Might have to try it again.

Once I switched over to Walthers DCC ready switches I have had ZERO electrical problems.

Which way are they going and on which route are they shorting? What brand GPs are you running? GPs should be fine and my current setup has one that Athearn SD60s run through fine. Could you post a photo of the switch?

The diverging route is actually the main line, and the straight route is a branch line. ( I didn't build the layout ).

Coming into the switch from the diverging route works fine, coming the opposite way is when it shorts.

I can take some video of what is happening if that would help.

The GPs are Atheran Genisis, I have 3 G38-2s and a GP-9

I also have a NCE power cab that I can use, I normally use it for programming, the MRC while limited in programming is actually easier to use when just running, and has a better display ( at least to me ). I've tried using the NCE and while I don't get the short message it does reset everything, and I have to turn locomotive headlights back on etc, the MRC requires me to unplug the hand controller to clear the SVDA message.

I do have what I'm pretty sure is a NCE circuit breaker in storage that came with the unit when I bought it, ( this controller came with another layout I bought several years ago ). Maybe switching to the NCE controller and installing the circuit breaker could fix the problem? Or at least help reduce it?

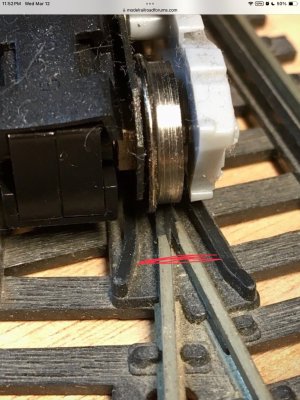

I took a couple photos of a SD40 truck taking the diverging route of an Atlas Snap Switch that is so old it says "Made in USA" on the back.

In this photo, you can see there is space behind the wheel approaching the frog. If the wheel or track gauge is too narrow the back of the wheel will short on the rail of the through route.

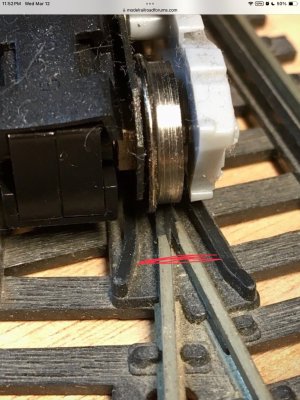

In the second photo, you can see the wheel leaving the frog. If the wheel tread is flat and wide, it can touch the end of the through route rail where it joins the frog. You could put a small piece of clear tape over that point and see if it fixes the issue. A more thorough fix could be grind the point of the frog down and rebuild it with a small piece of styrene, effectively increasing the distance between the rails as they meet at the frog.

I hope that helps,

Another possible solution:

Notice the fairly large gaps between the plastic guard rails and the stock rail (the rail to the left in the pic) and the frog rail (on the right).

If one were to glue a suitable thickness plastic shim to the guard rail on the left side in order to help reduce the gap, it would help keep the wheels pulled away from the frog as the trucks roll thru the turnouts. This in turn might help alleviate electrical shorting problems, and as an added bonus also help keep wheel flanges from picking the points. Generally this only needs to be done to the one guard rail on the stock rail of the curved portion of a turnout, but can also be done on the straight portion too in case it also gives problems.

Gomez Addams

Staff member

It would be a good idea to snap that retainer clip in place on the truck, it can't be helping.

The shorting on the diverging route is something I've experienced. I eliminated the problem by replacing the turnout with a Shinohara turnout.

Sometimes replacing with new is the way to go, providing the new thing is actually better. Here the OP is trying to get what he has to work well, which I think is possible. Also, hasn’t Shinohara been out of business for a few years now?

Gomez Addams

Staff member

Sometimes replacing with new is the way to go, providing the new thing is actually better. Here the OP is trying to get what he has to work well, which I think is possible. Also, hasn’t Shinohara been out of business for a few years now?

The definition of insanity is repeating the same task, and expecting a different outcome. I made the mistake of asking for help with the problem, and was summarily told to come off my checkbook and buy a quality turnout. Obviously, after so many years and still remembering the exact wording of that response, I believe it was unduly harsh.

Shinohara turnouts are still available at places like the online auction site, and Walthers turnouts are very similar, if needed.

Shinohara turnouts are still available at places like the online auction site, and Walthers turnouts are very similar, if needed.

Are either of these the same specs as the Atlas Snap Switch?

I would think the turnouts all have the same footprint.

Are either of these the same specs as the Atlas Snap Switch?

I would think the turnouts all have the same footprint.

None of the commercially made #4 switches (including Atlas Custom Line) have the same footprint as a Snap Switch, except the toy set ones that I posted in post #4 above. Snap Switches are made to replace an 18" radius curve piece in a layout. Here is a picture of an 18" radius piece laid on top; a 1/3 18" radius piece is needed to complete the curve off the divergent route of the switch. A normal divergent track on a #4 switch comes off the straight side and is pointed straight, not curved. This is why they (#4's) are not a drop-in fit for the Snap Switch that the OP is having problems with.

Refer to your second picture. You might be able to cut a break across the rails, a few mm below the plastic frog - where I’ve drawn a red line. Use a cutoff wheel or razor saw. This would make the insulated area larger and prevent the short, though you’d be more prone to stalling. Maybe add a capacitor to your loco and keep wheels and track clean, to minimize stalling.

-

IMG_1305.jpeg

415.2 KB

· Views: 55

Affiliate Disclosure: We may receive a commision from some of the links and ads shown on this website

(Learn More Here)