i would imagine that this is the best place if any to ask what DCC system is the best. i have been thinking about getting and MRC Prodigy. but i was wondering what you guys thought. i am 19 and just starting out in putting together my labor of love (reworking buildings for my layout) and i need to figure out which electrical system i will be using whether i will just use dc or go digital. i want to go digital because of how realistic it is. and i would like to know which system is most compatible with generic decoders and how expandable. any tips from you guys

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ing DCC system

- Thread starter Lab Rat

- Start date

ModelRailroadForums.com is a free Model Railroad Discussion Forum and photo gallery. We cover all scales and sizes of model railroads. Online since 2002, it's one of the oldest and largest model railroad forums on the web. Whether you're a master model railroader or just getting started, you'll find something of interest here.

why? just isolate one of your stabs and sidings and wire it with DPDT. drive the train in, flip the switch and suddenly its on program track. do your CV modifications, flip the switch again and drive off.

Affiliate Disclosure: We may receive a commision from some of the links and ads shown on this website (Learn More Here)

PNKFLOYD

Mikey

Lab Rat- This subject is open to lotsa personal opinions.

MRC Prodigy is rather inexpensive, limited in features and not very expandible. You need to carefully evaluated your future expansion and layout size before choosing a DCC system.

The two major system cussed and discussed here are Digitrax and NEC. These are a little harder to learn to operate, but offer many features and expansion options. They are also more expensive to purchase initially, but can save you money in the future.

Take a look in the DCC and electronics section of the forum for some of the problems and questions people have submitted. You may be able to find answers to questions you have not thought of yet.

If you have specific questions, ask here or in the DCC section.

Good luck and take your time making a decision.

MRC Prodigy is rather inexpensive, limited in features and not very expandible. You need to carefully evaluated your future expansion and layout size before choosing a DCC system.

The two major system cussed and discussed here are Digitrax and NEC. These are a little harder to learn to operate, but offer many features and expansion options. They are also more expensive to purchase initially, but can save you money in the future.

Take a look in the DCC and electronics section of the forum for some of the problems and questions people have submitted. You may be able to find answers to questions you have not thought of yet.

If you have specific questions, ask here or in the DCC section.

Good luck and take your time making a decision.

lmackattack

old school

yep lots of opinions and options. Here is my look on some systems

On my home layout I use MRC prodigy andvanced squared for a few reasons.

1)simplicity of understanding the system.

2)ease of operation

3)hand held walkaround throttle

4)cost

the MRC is one of the middle of the road entry level systems that does what most small layouts will do. Its not as expandable as others but IMO for a small home layout it is very nice.

I have used Digitraxx and NCE also at clubs and I would compair the NCE to MRC. NCE has more options than MRC as far as expanding. NCE has a simmilar walkaround cab and is very easy to understand the system

Digitraxx will have all the bells and whistles but I feel all their fancy options are really only used at a large clubs. I feel Digitraxx is somewhat difficult in the way they program and how the screen display works. For me Im just not a fan of them. I find it a PITA to do simple tasks. part of it is because I dont use the system as much as others and this just adds to the issue. But to put it in simple terms Its been 1 year and I still always mess up trying to program an engine at the club with digitraxx. with my MRC or NCE I was able to take the system out of the box, hook the system up to the layout and program an engine to run in under 10 mins. I suggest you test out a few systems and see what works. If you want to use computers to run layouts NCE and Digitraxx is what you should look into.

again just my .02!

On my home layout I use MRC prodigy andvanced squared for a few reasons.

1)simplicity of understanding the system.

2)ease of operation

3)hand held walkaround throttle

4)cost

the MRC is one of the middle of the road entry level systems that does what most small layouts will do. Its not as expandable as others but IMO for a small home layout it is very nice.

I have used Digitraxx and NCE also at clubs and I would compair the NCE to MRC. NCE has more options than MRC as far as expanding. NCE has a simmilar walkaround cab and is very easy to understand the system

Digitraxx will have all the bells and whistles but I feel all their fancy options are really only used at a large clubs. I feel Digitraxx is somewhat difficult in the way they program and how the screen display works. For me Im just not a fan of them. I find it a PITA to do simple tasks. part of it is because I dont use the system as much as others and this just adds to the issue. But to put it in simple terms Its been 1 year and I still always mess up trying to program an engine at the club with digitraxx. with my MRC or NCE I was able to take the system out of the box, hook the system up to the layout and program an engine to run in under 10 mins. I suggest you test out a few systems and see what works. If you want to use computers to run layouts NCE and Digitraxx is what you should look into.

again just my .02!

AyTrane

Member

I use the MRC Prodigy system, and love how easy it is to use. A few of the guys at the club also use it as well. The Digitrax unit we have on one of the club layouts is kind of confusing to use, but it does have the ability to be expanded into a very elaborate system capable of full automation. The NCE system is also very easy to use, although I did notice that if you switch between locos, the speed you have programmed into the hand held will stay the same, so it will change the speed of the locomotive you are trying to take control of. Example: Say train #1 was already moving at 50, you then switched over to train #2, which was stopped. You set the speed for that train at 40, then had to switch back to train #1, the speed on the controlled will still read 40, and then change the speed of train #1. That was the only problem I had with that system. I liked how the NCE system will reboot during a short, and still keep things going, the MRC system will stop all trains, but remember how fast they were going, so all you have to do is touch a speed notch to get the train going again at that original speed. I believe the Digitrax system operates similarly to the NCE, but you can control two trains at the same time with one throttle.

I'm sorry, I probably didn't make your decision any easier.

I'm sorry, I probably didn't make your decision any easier.

AyTrane

Member

Trent, MRC has a new device out that lets you hook the system into the computer and run trains, program CVs, and store train info into the computer...so if you ever lose it and have to re-program, it will be stored and easily up-loadable. They told me I'm supposed to be able to program speed curves very easily too (visually), but I haven't messed with that feature yet.

Selector

Well-Known Member

MRC makes good DCC systems, and so do all the rest. They work as they should across decoders from all sorts of manufacturers. However, they are not all the same. If you feel that expandability is, or might be, a concern in the future, then choose your initial purchase accordingly.

How about walk-around hand-held throttles? Are you going to be in a confined space, so you wouldn't mind having your controls mounted on one box?

Will you want to have to provide a separate programming track because your base controller must connect to such a track for address changes and such? Or, would you like to be able to programme without needing a dedicated programming track and leads to that track? For example, the somewhat pricey, and now dated, Super Empire Builder from Digitax provides you with the DB150 5 amp base controller that does everything out on the main if you want it to. No separate programming leads to a dedicated track, unless you want a dedicated track (another topic another time). It also comes with the DT400 hand-held throttle that actually has two encoder throttles on it...meaning you can run two trains simultaneously as easily as moving your forefinger and thumb 1.5" between the two knobs. The DB150 base controller can later be converted to a booster for a larger layout with just adding a set of jumper wires to the applicable terminals (all well explained in the manual).

All this to say that some beginner systems are essentially dead ends if you want 'more later'. Others can be expanded for future needs.

But assuming the heavy majority of us have a modicum of both literacy and intelligence, we can use any system we decide to purchase with some determination and patience....any one of them can be figured out. Some are more intuitive than others (NCE does well with this, or so I read here and there...), but I have used the Super Empire Builder as my first ever system for nearly four years now, and I never use the manual...haven't seen about week two. I only use it now if I want to look up an Ops Switch function in the table in the manual, and that is something left to another discussion.

You might be able to find use of the information about the various systems at places like Tony's Train Exchange http://tonystrains.com/productcompare/index.htm and Litchfield Station. http://www.litchfieldstation.com/DCC-University/index.htm

-Crandell

How about walk-around hand-held throttles? Are you going to be in a confined space, so you wouldn't mind having your controls mounted on one box?

Will you want to have to provide a separate programming track because your base controller must connect to such a track for address changes and such? Or, would you like to be able to programme without needing a dedicated programming track and leads to that track? For example, the somewhat pricey, and now dated, Super Empire Builder from Digitax provides you with the DB150 5 amp base controller that does everything out on the main if you want it to. No separate programming leads to a dedicated track, unless you want a dedicated track (another topic another time). It also comes with the DT400 hand-held throttle that actually has two encoder throttles on it...meaning you can run two trains simultaneously as easily as moving your forefinger and thumb 1.5" between the two knobs. The DB150 base controller can later be converted to a booster for a larger layout with just adding a set of jumper wires to the applicable terminals (all well explained in the manual).

All this to say that some beginner systems are essentially dead ends if you want 'more later'. Others can be expanded for future needs.

But assuming the heavy majority of us have a modicum of both literacy and intelligence, we can use any system we decide to purchase with some determination and patience....any one of them can be figured out. Some are more intuitive than others (NCE does well with this, or so I read here and there...), but I have used the Super Empire Builder as my first ever system for nearly four years now, and I never use the manual...haven't seen about week two. I only use it now if I want to look up an Ops Switch function in the table in the manual, and that is something left to another discussion.

You might be able to find use of the information about the various systems at places like Tony's Train Exchange http://tonystrains.com/productcompare/index.htm and Litchfield Station. http://www.litchfieldstation.com/DCC-University/index.htm

-Crandell

ok i guess i neglected to mention a few things that you guys brought up.

i will have a a programming track out of sight from the layout IE behind a hinged piece of fasia

i would most definataly be running two or more powered locotives in the same train

my first layout will be in a confined space and will be expanded as space becomes available.

i am planning on having controls near the origin of function(controls near what they will be controlling)

electronics is my strong point and layout will be built around such. my ooos and aahhs will come from such. buildings light independant from one another.

and the complexity of programming is no match for me i like it complex that way no one but me can work it lol. not to mention have you ever tried to program a robot in hexadecimal not fun and it takes forever.

and i was originally wanting to go with wireless or multiple plug in ports for the throttle pad.

i was also thinking of digital turnouts and switch overs for hoops.

hopefully this input narrows down my search results so to speak

i will have a a programming track out of sight from the layout IE behind a hinged piece of fasia

i would most definataly be running two or more powered locotives in the same train

my first layout will be in a confined space and will be expanded as space becomes available.

i am planning on having controls near the origin of function(controls near what they will be controlling)

electronics is my strong point and layout will be built around such. my ooos and aahhs will come from such. buildings light independant from one another.

and the complexity of programming is no match for me i like it complex that way no one but me can work it lol. not to mention have you ever tried to program a robot in hexadecimal not fun and it takes forever.

and i was originally wanting to go with wireless or multiple plug in ports for the throttle pad.

i was also thinking of digital turnouts and switch overs for hoops.

hopefully this input narrows down my search results so to speak

tankist

Active Member

ok i guess i neglected to mention a few things that you guys brought up.

i will have a a programming track out of sight from the layout IE behind a hinged piece of fasia

why? just isolate one of your stabs and sidings and wire it with DPDT. drive the train in, flip the switch and suddenly its on program track. do your CV modifications, flip the switch again and drive off.

can't agree there with you. i try to follow the KISS mentality as much as i can. there are always more then enough complications to resolve anywaysand the complexity of programming is no match for me i like it complex that way no one but me can work it lol. not to mention have you ever tried to program a robot in hexadecimal not fun and it takes forever.

Last edited by a moderator:

That's nice that you have such talent, but anyone else who might want to run your layout probably doesn't. At some point, you'll have your layout where you want to invite some other modelers or even just relatives to operate it. Do you want something you can teach them in five minutes or start hauling out hex to octal charts?

tankist

Active Member

hey lab rat, since you mentioned electronics as your strong point and programming a robot and such i was wondering if you can help or perhaps steer me at the right direction.

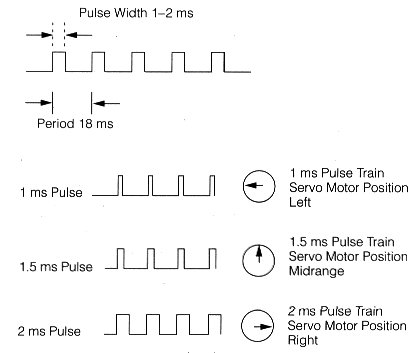

i'm looking for a way to convert servo signal originating in model plane R/C reciever into PWM pulse signal . any ideas?

i'm looking for a way to convert servo signal originating in model plane R/C reciever into PWM pulse signal . any ideas?

i hate to burst your bubble but pulse width modulation is what is used to control an rc servo well at least the servos i work with i would have to get out my books but i am pretty sure they are the same thing

hey lab rat, since you mentioned electronics as your strong point and programming a robot and such i was wondering if you can help or perhaps steer me at the right direction.

i'm looking for a way to convert servo signal originating in model plane R/C reciever into PWM pulse signal . any ideas?

see thats the thing anyone that i would invite over to let operate my layout would already be familiar with the system or they wouldnt be touching it. i am probably gonna use digitrax n the reason for not letting anyone touch it is i am paranoid when it comes to my trains i hate having to fix broken stuff espeacially high detail broken stuff

That's nice that you have such talent, but anyone else who might want to run your layout probably doesn't. At some point, you'll have your layout where you want to invite some other modelers or even just relatives to operate it. Do you want something you can teach them in five minutes or start hauling out hex to octal charts?

tankist could you explain your project and what is the difference i wavelengths from pwm n servo. when i was learning pwm i was using a BS2 from parallax it is a microcontroller that can be easily programmed if you go to there website forums and create a user name and post ur stuff more likely then not a guy named mike green will reply he is one of the best. tell them lab rat sent you. if you do go there use the sandbox forum. http://forums.parallax.com/forums/

mike green and the other guys help me alot when i am having problems

mike green and the other guys help me alot when i am having problems

tankist

Active Member

Yeah, you can't go wrong with digitrax really, DH163 is a 6 function decoder should provide you with enough room to play with

the project is to control tracked vehicle - 2 motors, each driving its respective side with steering accomplished by one side speeding up or slowing down. motors sit in MOSFET H bridge. standart radio control with 2 channels.

input should preferably be configurable between mixed operation ala Car (one channel sets the speed , the other sets steering direction by differentiating speeds) and streight ala tractor (each channel controls its respective motor). in this mode neutral servo signal ("keep centered") translated into 0% duty cycle (stop) and deflection will determine direction of each side.

i got several bits and pieces together already. some circuit schematics that somewhat meet the requirements. i have the MOSFET's, couple H bridge controller IC's, couple pic micro controllers and a pic programmer to try several things. it seems to me that it is the program in the pic that 99% determine the behavior, but creation of this code is one black hole to me.

so, how would you approach this?

(and yes, i am aware that products somewhat fitting the requirements exist premade off the shelf)

EDIT: i don't expect ready solution. but perhaps you could point me in right direction. i did quite a search, joined electronics forum but it is all not 100% of what i'd like to accomplish. i'm sure i could have missed something

the project is to control tracked vehicle - 2 motors, each driving its respective side with steering accomplished by one side speeding up or slowing down. motors sit in MOSFET H bridge. standart radio control with 2 channels.

input should preferably be configurable between mixed operation ala Car (one channel sets the speed , the other sets steering direction by differentiating speeds) and streight ala tractor (each channel controls its respective motor). in this mode neutral servo signal ("keep centered") translated into 0% duty cycle (stop) and deflection will determine direction of each side.

i got several bits and pieces together already. some circuit schematics that somewhat meet the requirements. i have the MOSFET's, couple H bridge controller IC's, couple pic micro controllers and a pic programmer to try several things. it seems to me that it is the program in the pic that 99% determine the behavior, but creation of this code is one black hole to me.

so, how would you approach this?

(and yes, i am aware that products somewhat fitting the requirements exist premade off the shelf)

EDIT: i don't expect ready solution. but perhaps you could point me in right direction. i did quite a search, joined electronics forum but it is all not 100% of what i'd like to accomplish. i'm sure i could have missed something

Last edited by a moderator:

Affiliate Disclosure: We may receive a commision from some of the links and ads shown on this website (Learn More Here)