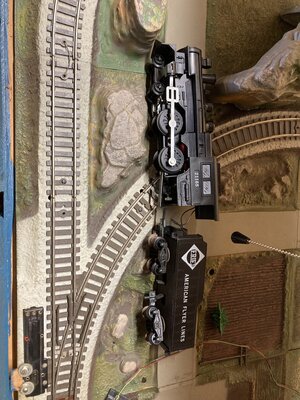

Hello everyone! My family moved into an older house and this track and transformer were here. I know nothing about model trains but I’m trying to find an engine that will work for my son. I do know that the transformer works. Any help appreciated. Thank you!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Howdy! Trying to find an engine that will work on this S Scale Layout.

ModelRailroadForums.com is a free Model Railroad Discussion Forum and photo gallery. We cover all scales and sizes of model railroads. Online since 2002, it's one of the oldest and largest model railroad forums on the web. Whether you're a master model railroader or just getting started, you'll find something of interest here.

Other items will need to be checked and probably cleaned, but as an HO and OO scaler, I'm not that familiar with S scale or that locomotive. and I wouldn't want to advise you any further other than the simple basics. You may find you'll have to remove the bodyshell to get to all the parts, but it's all pretty basic to work out, hopefully, you have the exploded diagram which will also help.

Our S scale members will be able to advise you in more detail than I can, but a clean set of wheels and tracks is a must in any scale.

Another part of these old Flyer "Pike Master" locos that always needs attention is the "E-Unit"; the reversing unit mounted on the back of the motor. It is a solenoid-driven device that will always have tarnished contacts after years of not being operated. The commutator contacts on the motor itself are probably also tarnished. Getting these locos apart without breaking something is tricky, so before attempting that make sure the motor will rotate freely by taking a match stick or something soft to push the motor armature around to see if it will rotate at all. If it rotates without a lot of pressure, you know the bearings aren't clogged with old lubricant. If not, the armature bearings may be clogged. Usually, they're just dry. A drop of oil on the bottom bearing (seen from underneath the chassis) may loosen up the armature. If your loco has a "button" on the roof of the cab toward the cab's front, check to see if it can be pulled out. If it can be, you can oil the top motor bearing through the hole in the roof without removing the loco shell.

The loco you have looks like it's in good shape. Unfortunately, the Pike Master series locos were not made for easy servicing. You can't just unscrew things. Disassembly of the loco involves spreading the shell apart at the cab where the chassis' metal tabs stick out of the sides underneath the loco #s. You've got to spread the shell just enough that it will release the tabs but won't crack the shell itself. (That's a narrow window of motion.) Before attempting that, I'd try exercising the E-unit by pulling and pushing the reverse lockout tab on the E-unit. That's the unpainted metal tab below the E-unit near the back wall of the cab. Pull the tab down and push it back up a few times. A spritz of plastic-safe contact cleaner may help with tarnished contacts.

The tender shell comes off by straightening a bent tab in one corner of the tender's metal floor. The floor is very thick steel, so unless there's a broken wire within the tender, there's nothing to service in there anyway. Unlike earlier AF steamers, the tender wires plug into the tender itself, instead of being soldered from tender to loco. May I assume that you've checked for voltage at the transformer's terminals, then at the track, then at the contact eyelets on the tender? There's a circuit breaker inside the transformer. I don't know if it is self-resetting or not; check for a reset button.

The Pike Master/All Aboard system came late in the Gilbert era of American Flyer, about 1961. The 4-4-0 "Casey Jones" loco you have is from that time. The design incorporated several extreme cost-cutting features, such as the loco chassis being folded from heavy gauge steel instead of being cast from zamac. One good thing; the drive wheel axles have bronze bushings for bearings (as opposed to bare holes in zamac). Be sure those are oiled as well.

Sorry I can't be more detailed here. Hopefully this will get you running. Btw, though its cab is a bit wide--presumably to make room for the motor--this particular American Flyer steamer is a fairly decent rendering of an early (1895) PRR D16 4-4-0 with slide valves, one of the most powerful and among the last of the "American Standard" 4-4-0 wheel arrangement. They soldiered on into the 1920s IINM.

Affiliate Disclosure: We may receive a commision from some of the links and ads shown on this website (Learn More Here)

santafewillie

Same Ol' Buzzard

Reword the thread title to include S scale in it to get more responses.

Thanks for the heads up!Reword the thread title to include S scale in it to get more responses.

Thank you!American flyer. S scale. I do believe we have a good number of s scale guys here who can help

Can’t seem to be able to reword the thread title. Should I start a new thread?Reword the thread title to include S scale in it to get more responses.

santafewillie

Same Ol' Buzzard

Yes I would.Can’t seem to be able to reword the thread title. Should I start a new thread?

It's already taken care of.Yes I would.

Thank ya!It's already taken care of.

Smudge617

Well-Known Member

Some work will probably be needed as this has likely been sitting around for some time before it was sold, looking at your photo a good clean of the wheels is needed, also any pickups, clean wheels, pickups and track are important for the power to reach the motor, try that first and see if it improves its performance.I should also mention that I did a little (unsuccessful) research of my own before and bought this American Flyer S Gauge from eBay. I couldn’t get it to quite work. Maybe it doesn’t fit the track correctly?

Other items will need to be checked and probably cleaned, but as an HO and OO scaler, I'm not that familiar with S scale or that locomotive. and I wouldn't want to advise you any further other than the simple basics. You may find you'll have to remove the bodyshell to get to all the parts, but it's all pretty basic to work out, hopefully, you have the exploded diagram which will also help.

Our S scale members will be able to advise you in more detail than I can, but a clean set of wheels and tracks is a must in any scale.

santafewillie

Same Ol' Buzzard

Smudge offers good advice here. While I am not an S scaler, I can advise that as a beginner when you disassemble any steam locomotive, it is advisable to take pictures as you go. Then you have guides as to how it goes back together.

Guy64

Member

The loco you have is the right vintage for the "All Aboard" layout system you have. I concur with all that's been said about the importance of clean pickup wheels (found on the tender), and especially clean track. From your pic, it looks like the rails are lightly "toned" from age. Fortunately, they don't appear to have any rust on them (The steel rails are plated with tin.) I use a Scotch-Brite pad for cleaning the tops of tinplate rail.I should also mention that I did a little (unsuccessful) research of my own before and bought this American Flyer S Gauge from eBay. I couldn’t get it to quite work. Maybe it doesn’t fit the track correctly?

Another part of these old Flyer "Pike Master" locos that always needs attention is the "E-Unit"; the reversing unit mounted on the back of the motor. It is a solenoid-driven device that will always have tarnished contacts after years of not being operated. The commutator contacts on the motor itself are probably also tarnished. Getting these locos apart without breaking something is tricky, so before attempting that make sure the motor will rotate freely by taking a match stick or something soft to push the motor armature around to see if it will rotate at all. If it rotates without a lot of pressure, you know the bearings aren't clogged with old lubricant. If not, the armature bearings may be clogged. Usually, they're just dry. A drop of oil on the bottom bearing (seen from underneath the chassis) may loosen up the armature. If your loco has a "button" on the roof of the cab toward the cab's front, check to see if it can be pulled out. If it can be, you can oil the top motor bearing through the hole in the roof without removing the loco shell.

The loco you have looks like it's in good shape. Unfortunately, the Pike Master series locos were not made for easy servicing. You can't just unscrew things. Disassembly of the loco involves spreading the shell apart at the cab where the chassis' metal tabs stick out of the sides underneath the loco #s. You've got to spread the shell just enough that it will release the tabs but won't crack the shell itself. (That's a narrow window of motion.) Before attempting that, I'd try exercising the E-unit by pulling and pushing the reverse lockout tab on the E-unit. That's the unpainted metal tab below the E-unit near the back wall of the cab. Pull the tab down and push it back up a few times. A spritz of plastic-safe contact cleaner may help with tarnished contacts.

The tender shell comes off by straightening a bent tab in one corner of the tender's metal floor. The floor is very thick steel, so unless there's a broken wire within the tender, there's nothing to service in there anyway. Unlike earlier AF steamers, the tender wires plug into the tender itself, instead of being soldered from tender to loco. May I assume that you've checked for voltage at the transformer's terminals, then at the track, then at the contact eyelets on the tender? There's a circuit breaker inside the transformer. I don't know if it is self-resetting or not; check for a reset button.

The Pike Master/All Aboard system came late in the Gilbert era of American Flyer, about 1961. The 4-4-0 "Casey Jones" loco you have is from that time. The design incorporated several extreme cost-cutting features, such as the loco chassis being folded from heavy gauge steel instead of being cast from zamac. One good thing; the drive wheel axles have bronze bushings for bearings (as opposed to bare holes in zamac). Be sure those are oiled as well.

Sorry I can't be more detailed here. Hopefully this will get you running. Btw, though its cab is a bit wide--presumably to make room for the motor--this particular American Flyer steamer is a fairly decent rendering of an early (1895) PRR D16 4-4-0 with slide valves, one of the most powerful and among the last of the "American Standard" 4-4-0 wheel arrangement. They soldiered on into the 1920s IINM.

Last edited:

Affiliate Disclosure: We may receive a commision from some of the links and ads shown on this website (Learn More Here)