kjchronister

Member

So my beloved heritage 2882 is toast.

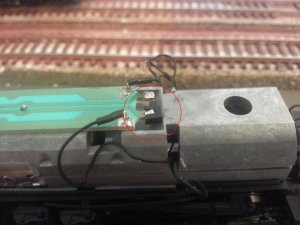

Sounds work. Lights work. No motion. I've swapped in known - good decoders and no difference. It's not the decoder. I put in a dc blanking plate, same: no go. I used wires from a dc power supply direct to the motor terminals and it ran like a champ. I've checked all the wires, harnesses, etc. All good. But no matter what I do, something is keeping this thing from the motor running.

I'm about ready to give up. Done everything I know. According to every ounce of my 30-some years mrr experience, and my multimeter, it should be running. But no dice.

Any recommendations for who can help? I'm done. At this point my options are find someone better than me to diagnose/fix, sell it for peanuts as a non runner on ebay, or just relegate it to the display case...?

It's been one of my best locos for years, and I hate to see it go. But I'm past my ability to do more and no idea what's next.

Sounds work. Lights work. No motion. I've swapped in known - good decoders and no difference. It's not the decoder. I put in a dc blanking plate, same: no go. I used wires from a dc power supply direct to the motor terminals and it ran like a champ. I've checked all the wires, harnesses, etc. All good. But no matter what I do, something is keeping this thing from the motor running.

I'm about ready to give up. Done everything I know. According to every ounce of my 30-some years mrr experience, and my multimeter, it should be running. But no dice.

Any recommendations for who can help? I'm done. At this point my options are find someone better than me to diagnose/fix, sell it for peanuts as a non runner on ebay, or just relegate it to the display case...?

It's been one of my best locos for years, and I hate to see it go. But I'm past my ability to do more and no idea what's next.