SilverBlade

Member

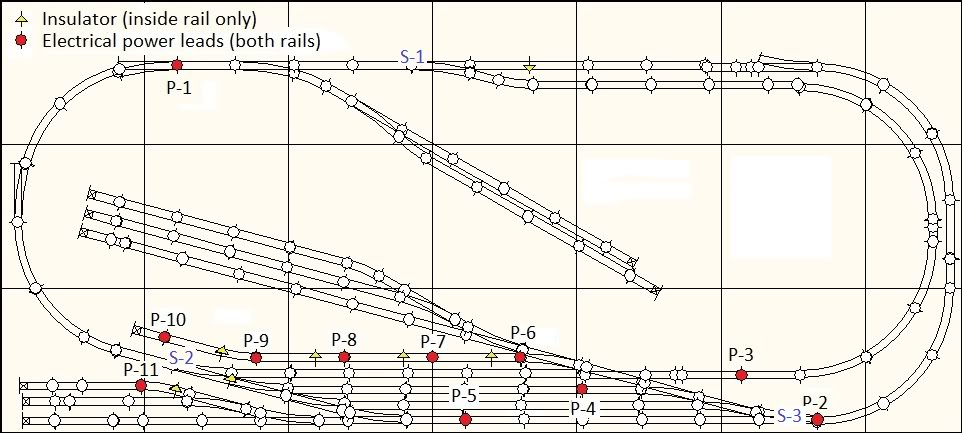

I am stumped by this short circuit. It makes no sense to me at all. If you guys can help me out here I'll give you a big sloppy kiss. Here is my layout so far:

I'm using Peco Insulfrog turnouts.

OK here's my problem: I wired up P-1, P-2, and P-4 without any trouble. I can move trains between the main line and the yard normally. But as soon as I hook up P-3 I get a short on the main line. I can still run through the yard, but if I switch either turnout S-1 or S-2 to the main line my loco slows to a crawl. Switch both S-1 & S-2 and it dies completely. But here is what really stumps me: Disconnect P-3 and the problem still exists! I've gone through this several times. P-1, 2, & 4 don't cause a problem but once P-3 is wired in the main line shorts and the short doesn't go away when P-3 is disconnected. Then a few days later the short circuit fairy comes and waves a magic wand and the main line just starts working again.

WTF!!!

None of the electrical leads above P-4 are connected right now and none of the turnouts are powered yet. Because of computer issues I can't post a pic of the wiring but I've traced all the wires a dozen times and absolutely nothing is crossed. It's all above table right now anyway so it's fairly easy for me to be sure. P-1 is close to the power supply but P-2, 3, & 4 have to be spliced together into 1 wire before I run them to the power supply. But again I am certain the polarities are separate so why should that be a problem?

Peco turnouts are power routing (which I've decided I really don't like) but surely they don't reverse polarity, right?!

I've been studying this for 2 weeks and it just doesn't make a bit of sense to me. Please help!

I'm using Peco Insulfrog turnouts.

OK here's my problem: I wired up P-1, P-2, and P-4 without any trouble. I can move trains between the main line and the yard normally. But as soon as I hook up P-3 I get a short on the main line. I can still run through the yard, but if I switch either turnout S-1 or S-2 to the main line my loco slows to a crawl. Switch both S-1 & S-2 and it dies completely. But here is what really stumps me: Disconnect P-3 and the problem still exists! I've gone through this several times. P-1, 2, & 4 don't cause a problem but once P-3 is wired in the main line shorts and the short doesn't go away when P-3 is disconnected. Then a few days later the short circuit fairy comes and waves a magic wand and the main line just starts working again.

WTF!!!

None of the electrical leads above P-4 are connected right now and none of the turnouts are powered yet. Because of computer issues I can't post a pic of the wiring but I've traced all the wires a dozen times and absolutely nothing is crossed. It's all above table right now anyway so it's fairly easy for me to be sure. P-1 is close to the power supply but P-2, 3, & 4 have to be spliced together into 1 wire before I run them to the power supply. But again I am certain the polarities are separate so why should that be a problem?

Peco turnouts are power routing (which I've decided I really don't like) but surely they don't reverse polarity, right?!

I've been studying this for 2 weeks and it just doesn't make a bit of sense to me. Please help!

Last edited by a moderator: