Maxitrains

Member

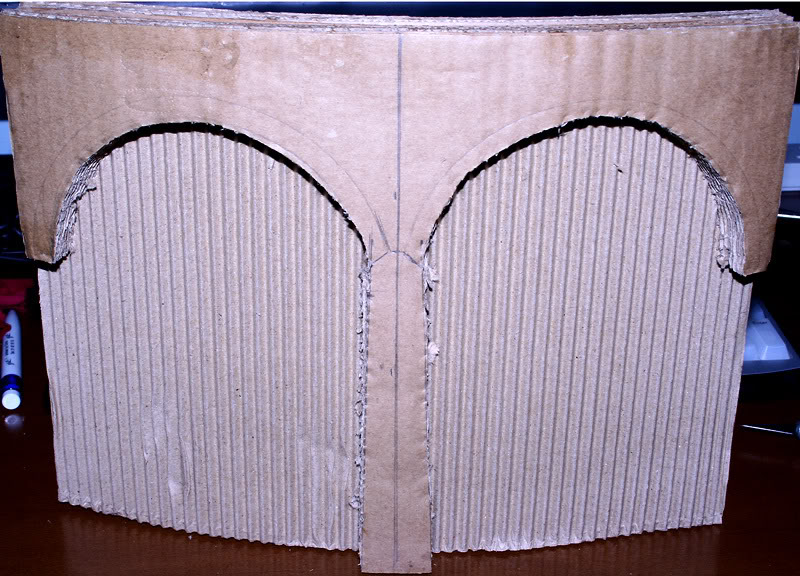

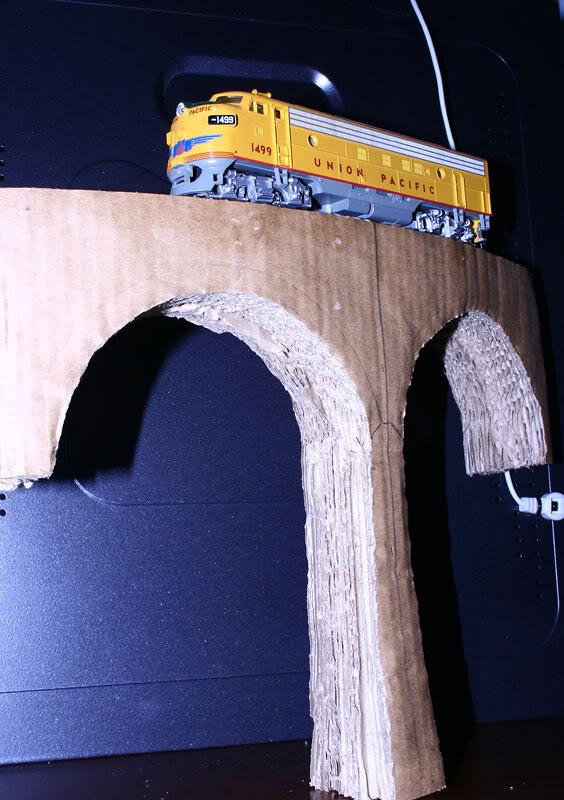

OK, so here is my thread about the curved stone viaduct which I need for the upper rail, over the river and lower dockside line. I'm building this in carton, I hope it works, I made a sort of mould to hold the layers of carton while the glue dries up, holding them in the curve I want them, then once dry I drew up what the arches had to look lke and started cutting up the shape. After that I have to apply mosr glue to it, so it solidifies and will be a robust structure. After that I will start coating in plaster to give more body and could be able to sculpture the bricks, or else I can print some brick paper and apply on it, but sculpturing has a more dramatic effect. Here are some photos of the process.