kjchronister

Member

Hey gang, so after a year of insanity... New job, new house, etc... The layout is officially under construction. I'll post updates and info here, and those interested are welcome to read/comment.

Today, I'll post three things, reflecting three days of activity. Then quicker more focused updates as progress occurs. Love to hear your feedback, thanks in advance.

Day 1: Room Prep & Layout Planning

On Friday, I cleared out the train room (photos attached). I re-measured and good thing I did... I was a foot off on one key measurement. Reworked the layout plan to reflect that.

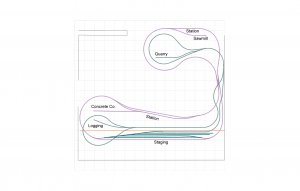

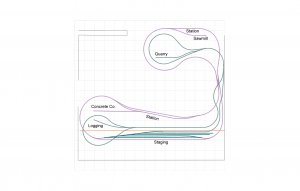

The layout plan is for the "Clifton & Woodville" branch of the PRR. Mostly to accommodate the huge amount of PRR motive power and rolling stock I own. The quick version is that Clifton is (shock!) a town below a set of bluffs, defined by its concrete factory. Woodville is on the same line, defined by its sawmill, which drives the local economy. Woodville is the 'end' of a PRR branch line along which Clifton also sits. Trains come and go from 'the big town' (probably Harrisburg) represented by staging.

Driving the plan on a practical basis:

So here's the plan... quick guide: Purple is main-level, main-line. Green is upper level (not another deck, just elevated). Staging area is at the bottom and the orange line is a backdrop concealing staging.

Look for a couple more posts on the train room and the first stages of benchwork.

Today, I'll post three things, reflecting three days of activity. Then quicker more focused updates as progress occurs. Love to hear your feedback, thanks in advance.

Day 1: Room Prep & Layout Planning

On Friday, I cleared out the train room (photos attached). I re-measured and good thing I did... I was a foot off on one key measurement. Reworked the layout plan to reflect that.

The layout plan is for the "Clifton & Woodville" branch of the PRR. Mostly to accommodate the huge amount of PRR motive power and rolling stock I own. The quick version is that Clifton is (shock!) a town below a set of bluffs, defined by its concrete factory. Woodville is on the same line, defined by its sawmill, which drives the local economy. Woodville is the 'end' of a PRR branch line along which Clifton also sits. Trains come and go from 'the big town' (probably Harrisburg) represented by staging.

Driving the plan on a practical basis:

- I really prefer passenger operations and equipment

- But my second love is geared locos, ore cars and log cars...

- I am generally a lone wolf vis-a-vis the home layout.]

- Operationally, I like a good bit of "roundy round" just letting the trains run, with some "staging out and back" ops and sometimes driving trains from the mining/logging areas to their respective industries for delivery.

- I've had three layouts in the past couple decades, two of which never got past "plywood central" and only one of which I did any scenicking on at all. Currently part of the driver is something more manageable...

So here's the plan... quick guide: Purple is main-level, main-line. Green is upper level (not another deck, just elevated). Staging area is at the bottom and the orange line is a backdrop concealing staging.

Look for a couple more posts on the train room and the first stages of benchwork.