ModelRailroadForums.com is a free

Model Railroad Discussion Forum and

photo gallery. We cover all scales and sizes of model railroads. Online since 2002, it's one of the oldest and largest model railroad forums on the web. Whether you're a master model railroader or just getting started, you'll find something of interest here.

Hi there i was wondering if some one would tell me what the best can motor for a rivarossi 2-8-8-2 would be thinking of adding dcc to it

Tia.

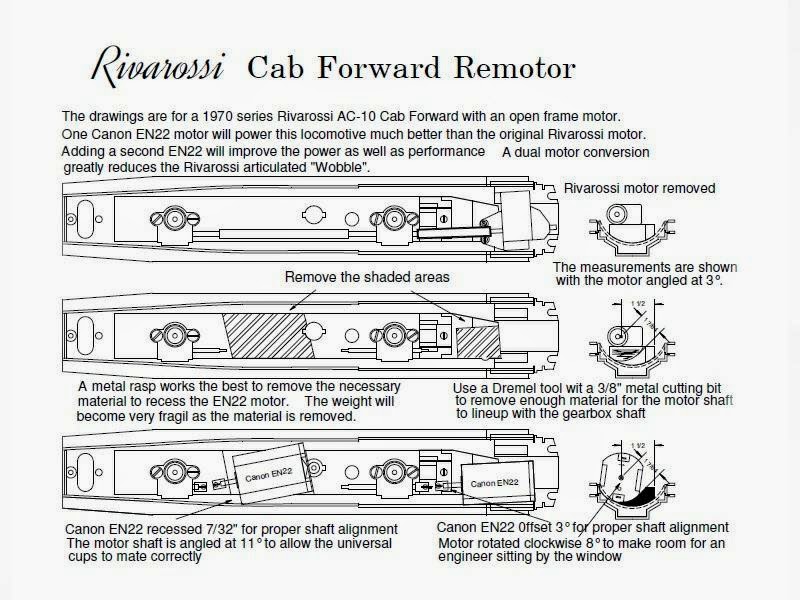

roundbell.com

I have no history with this site or its owners. Just googled. If you call, they may even know two or three possible substitutes. Or, call another site.

Okay thankyou will take a look at it.

Boy would I love to convert mine, as well !! Not saying I have the gumption..But if I wanted to attempt a first time motor conversion THIS would be it !! I have that same Riv sitting atop the air conditioner in my room; just a static y6b (my fav articulated) with it's original clunky DC frame motor and too deep flanges..(which, too would require turning down, as well as a DCC/Sound install)....They're quite good lookers, otherwise....

Here's hoping you're successful with yours....P

Have a couple of the Riv BigBoys that also need remotored and have pizza cutter flanges. So my question is: Is it better to grind and/or turn said flanges from the backside to keep the gauge in check, or go for broke and get them down then regauge them? Looks like either way each axel would need to come out of the chassis, wondering which would be easier.

I have already done 3 of the 2-8-8-2's. They run fine on my code 100 track but are quite noisy on code 83. I bought a Sigami can motor at a train show and decided to give it a try. I ground out the center of the Rivarossi weight to accommodate the new motor and secured it with silicone calk. I cut down the drive shafts from both gear towers and super glued NSWS universal joints to the motor and shafts. Added the DCC and put the speaker in the nose (sounds better than it does in the tender). The first unit has been running for about 15 years, without any problems.

Well, one problem. We decided to see how many coal hoppers it would pull up a 2% grade. we had 50 Athearn hoppers behind a single unit,which it pulled fine. We kept have problems with derailments in the curve. It turned out that the new motor had so much torque that it was lifting the lead wheels on each set of drivers off the track, so it wouldn't follow the track in the turns

All but one wheel move the rear truck of my mallet any idea how to fix it so i can run it tia.

Not sure if I am remembering my original modification to the articulated Rivarossi (s) (two of them at least),... as it was a long time ago, and I have since sold them off.

I think I left the 'cookie cutter wheels' as they were, since they did not have problems on Code 100 track.

I did end up adding two identical cheap can motors to each of them,...running each set of 'engines/trucks' That worked out really good. I used identical motors so they would run consistently on just plain DC.

And with some weathering and real coal they looked really good (one ignored the big flanges).

I seem to remember cutting the flanges down on a smaller Riv loco,....ran the loco while holding it against a block of course sandpaper

Well, one problem. We decided to see how many coal hoppers it would pull up a 2% grade. we had 50 Athearn hoppers behind a single unit,which it pulled fine. We kept have problems with derailments in the curve. It turned out that the new motor had so much torque that it was lifting the lead wheels on each set of drivers off the track, so it wouldn't follow the track in the turns

Did you ever solve that problem??

Affiliate Disclosure: We may receive a commision from some of the links and ads shown on this website

(Learn More Here)