paper-tiger

Member

http://www.paper-tiger.org/2014/12/09/riverside-blue-line-layout-rethink/

Apologies for the remote link for image and further verbosely extended description. The forum apparently does not play well with attachments from iPads and my family is monopolizing the desktop...

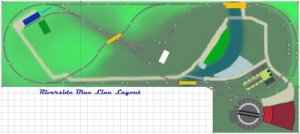

Hello there! This is the layout that I'm currently attempting to (re)start in the basement. I have a son who LOVES model trains and whose favorite thing is to watch the wheels run at about eye level. The layout I have here is 39" deep and 135" long with an extra little 21" L on the bottom. I have discovered that it is exactly wide enough for a single complete turnaround loop of HO EZ Track (my only available weapon at this level) and have been trying to come up with an idea that incorporates lots of continuous running with the potential to switch things up (literally) and a few spurs to suggest legitimacy.

The weird shape is because I'm trying to recycle as much of my bench work from the last colossal failure as I can. I know I have plenty of space for the 'big' run up on the right, but I'm wondering if I'll be too cramped for space coming back down the front edge. I don't plan on running any more than 4 or 5 cars (we don't even have that many at the moment) and unless there is an incredibly simple and intuitive way to convert steel EZ Track to DCC, this will be a DC layout.

Any thoughts or suggestions would be most welcome! Thank you!

(Assembled with AnyRail and Photoshop)

Apologies for the remote link for image and further verbosely extended description. The forum apparently does not play well with attachments from iPads and my family is monopolizing the desktop...

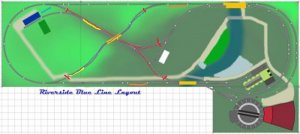

Hello there! This is the layout that I'm currently attempting to (re)start in the basement. I have a son who LOVES model trains and whose favorite thing is to watch the wheels run at about eye level. The layout I have here is 39" deep and 135" long with an extra little 21" L on the bottom. I have discovered that it is exactly wide enough for a single complete turnaround loop of HO EZ Track (my only available weapon at this level) and have been trying to come up with an idea that incorporates lots of continuous running with the potential to switch things up (literally) and a few spurs to suggest legitimacy.

The weird shape is because I'm trying to recycle as much of my bench work from the last colossal failure as I can. I know I have plenty of space for the 'big' run up on the right, but I'm wondering if I'll be too cramped for space coming back down the front edge. I don't plan on running any more than 4 or 5 cars (we don't even have that many at the moment) and unless there is an incredibly simple and intuitive way to convert steel EZ Track to DCC, this will be a DC layout.

Any thoughts or suggestions would be most welcome! Thank you!

(Assembled with AnyRail and Photoshop)