You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Articulated Joint on Model RR Container Cars

- Thread starter beiland

- Start date

ModelRailroadForums.com is a free Model Railroad Discussion Forum and photo gallery. We cover all scales and sizes of model railroads. Online since 2002, it's one of the oldest and largest model railroad forums on the web. Whether you're a master model railroader or just getting started, you'll find something of interest here.

Yes, Steve that was the first though that entered my mine. I began to try adjust the tightness of the trucks as a first experiment,...though I arrived at a solution, but subsequently discovered I had not solved everything.

What end of a single car does one allow the more loosely tightened truck? or does one look at the two car (or multiple car) arrangement to accomplish some sort of 3-point suspension?? (or a single car, or a pair, or 3, etc)?

That's when I began to take a closer look at the 'freedom of movements' at this articulation joint. Both the conical shaped base and the height of that central pin come into question. The conical base certainly allows for free swing movement, but if the 'upright pin' is too tall or too tight, the freedom of movement is definitely affected,...both bending wise between cars, and swaying/tipping wise.

Is the conical base really needed? The new ScaleTrain models doesn't seem to think so.

Is the fit around that vertical pin really need to be that firm, or is a more tolerate fit better??

I like how on the prototype, it appears that the wheel set and bearing on the right have been changed out.

-Greg

I have 2 different Atlas models of these articulated car sets,...both very nice models.

These cars do have a different bolster truck design. I took them straight out of the new box and ran them thru my troublesome Peco curved switch with NO SHIMS. They worked beautifully,..no derails, very smooth operation.

I then try to bend them around their articulated joint,...and compare that with the container cars. Here you can see that there is more freedom of movement between the double cars of the autoracks verses the container cars,..

There was one articulation that caught my attention more than the others,....the relative twisting motion that would allow the cars to roll more in relation to one another. The autoracks were more supple than the container cars,...they could roll a bit more then the pretty stiff container cars. I caulked this up as a rigidness with the container car connection compared with the autoracks. Perhaps this more rigid nature was contributing to their derailing more easily?

My next experiment was to loosen up the every truck screw on metal container cars that had appeared to be extra rigid. SURPRISE, now they flowed thru that troublesome Peco with no derailments.

(not sure yet how it will effect their tippy-ness when loaded with double high containers?)

EDITED: articulation arrangement

Brian

Just wish to express how delighted I was with the running of these Atlas articulate autoracks, ....really nice, AND able to take relatively small radius track (at least 22" in my experiment). I just happened to have acquired 2+2 sets at a very good price a number of years ago at the Timonium train show.

I even spent considerable effort to make them fit thru some pretty tight spaces on my upper helix loop track where it reenters the train shed.

The other 2 sets are the Auto Max

BTW, 22' radius is the bare minimum

What end of a single car does one allow the more loosely tightened truck? or does one look at the two car (or multiple car) arrangement to accomplish some sort of 3-point suspension??

That's when I began to take a closer look at the 'freedom of movements' at this articulation joint. Both the conical shaped base and the height of that central pin come into question. The conical base certainly allows for free swing movement, but if the 'upright pin' is too tall or too tight, the freedom of movement is definitely affected,...both bending wise between cars, and swaying/tipping wise.

Is the conical base really needed? The new ScaleTrain models doesn't seem to think so.

Is the fit around that vertical pin really need to be that firm, or is a more tolerate fit better??

Brian

I'd be interested in exactly how do you add those pennies to your containers?

These Walthers metal framed cars seem to have enough weight to travel unloaded,...but what about those many other plastic cars?

One thought goes to adding the weight to the bottom container. But many of those containers are closed plastic boxes that have no seam to open up to put in weights. Just wondering what other solutions have been tried with adding weight to those containers themselves??

Later

Affiliate Disclosure: We may receive a commision from some of the links and ads shown on this website (Learn More Here)

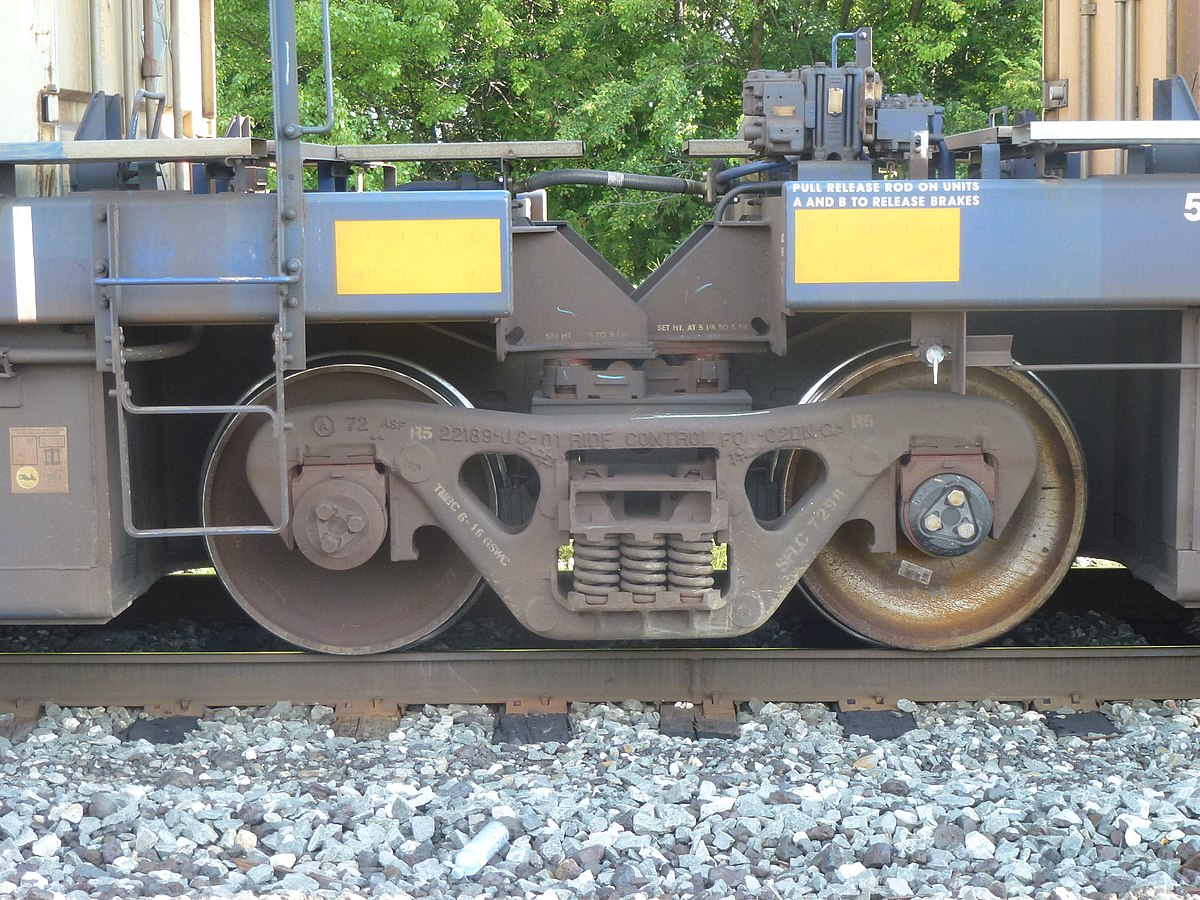

A gentleman on another forum offered this photo

I replied,

That doesn't look like any of my model rr articulated container car joins ?

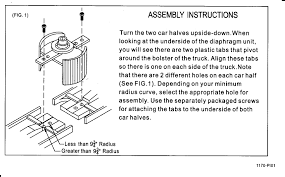

Thought I might find something here,...but can't interpret this yet

https://www.trackopedia.info/encyclopedia/railway-vehicles/types-of-bogies

I replied,

That doesn't look like any of my model rr articulated container car joins ?

Thought I might find something here,...but can't interpret this yet

https://www.trackopedia.info/encyclopedia/railway-vehicles/types-of-bogies

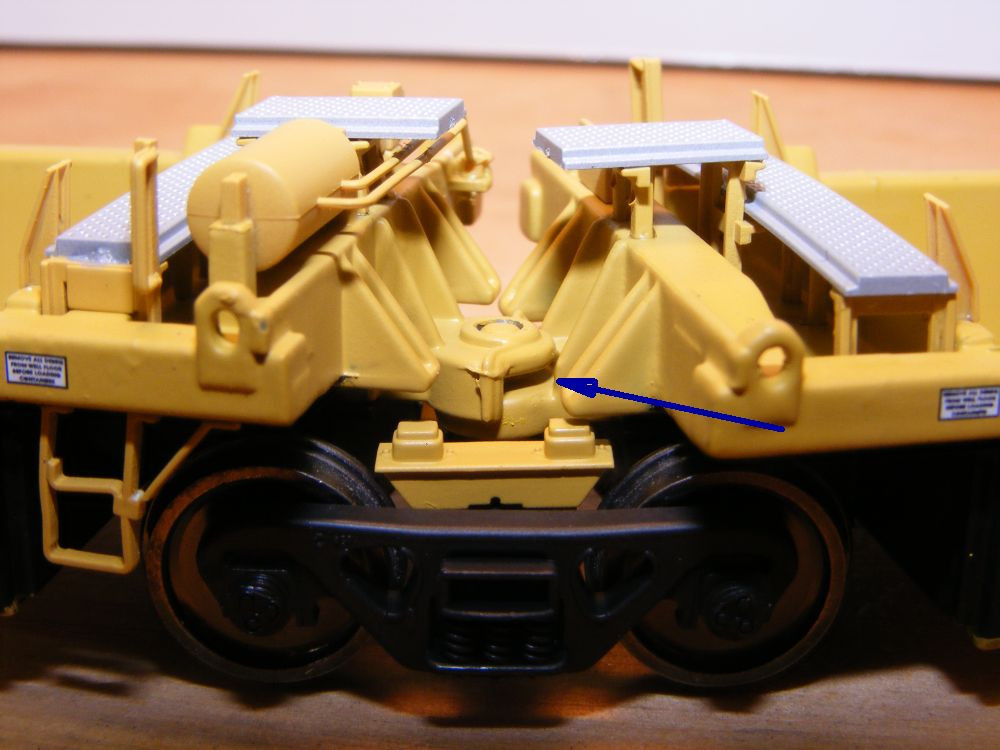

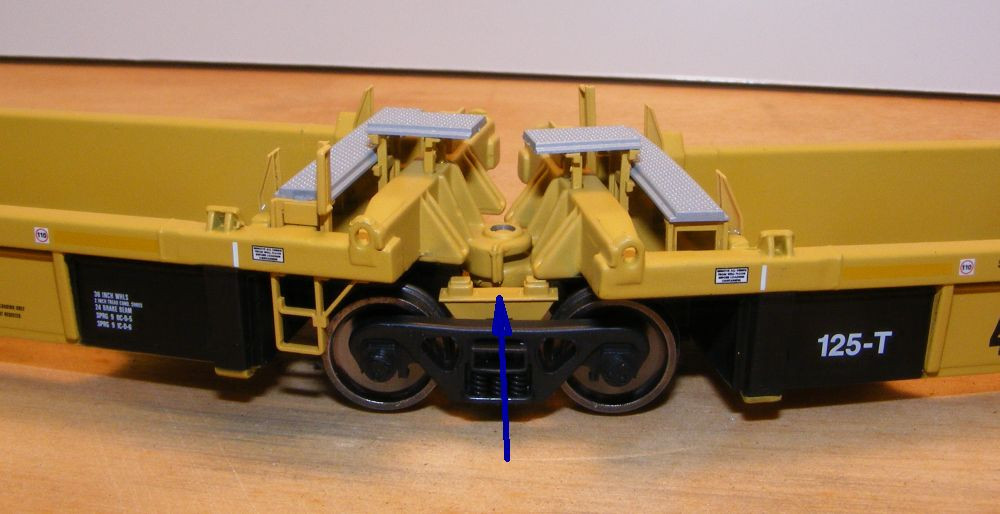

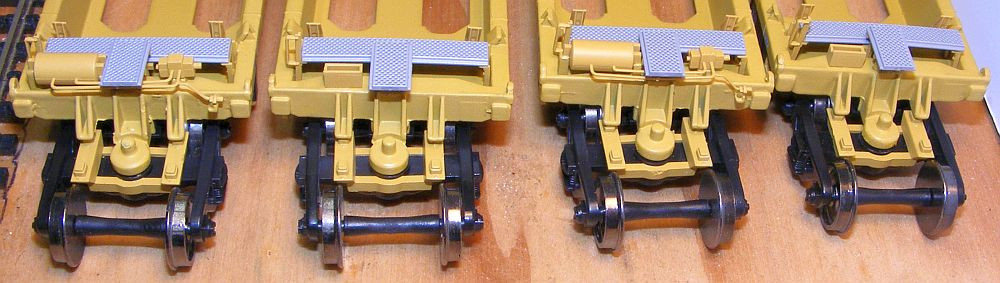

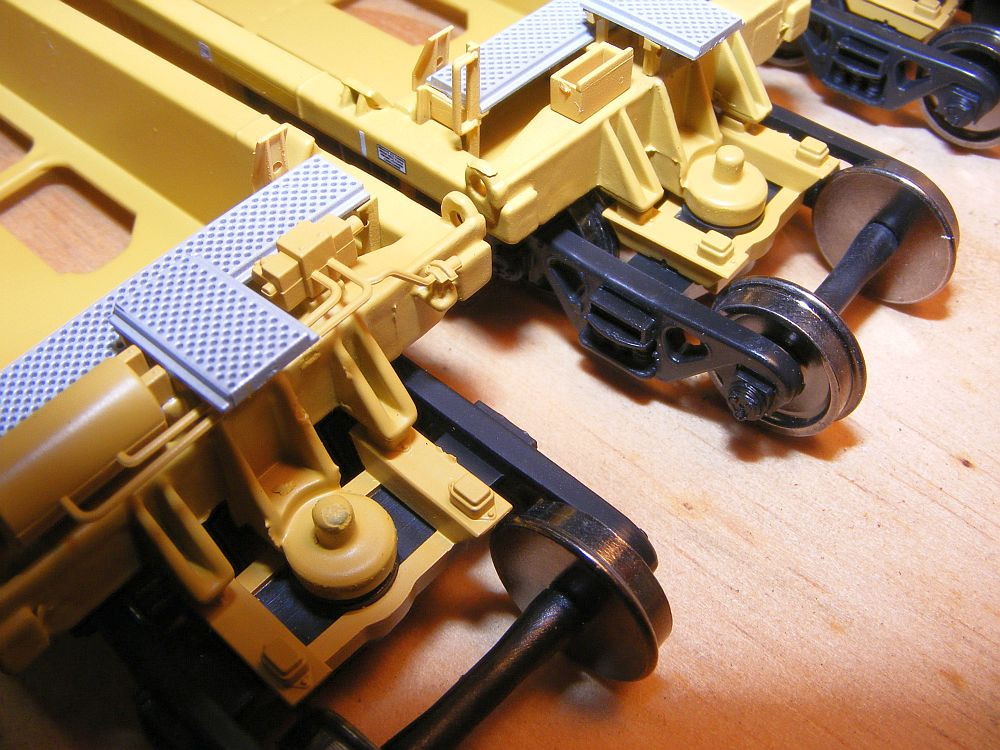

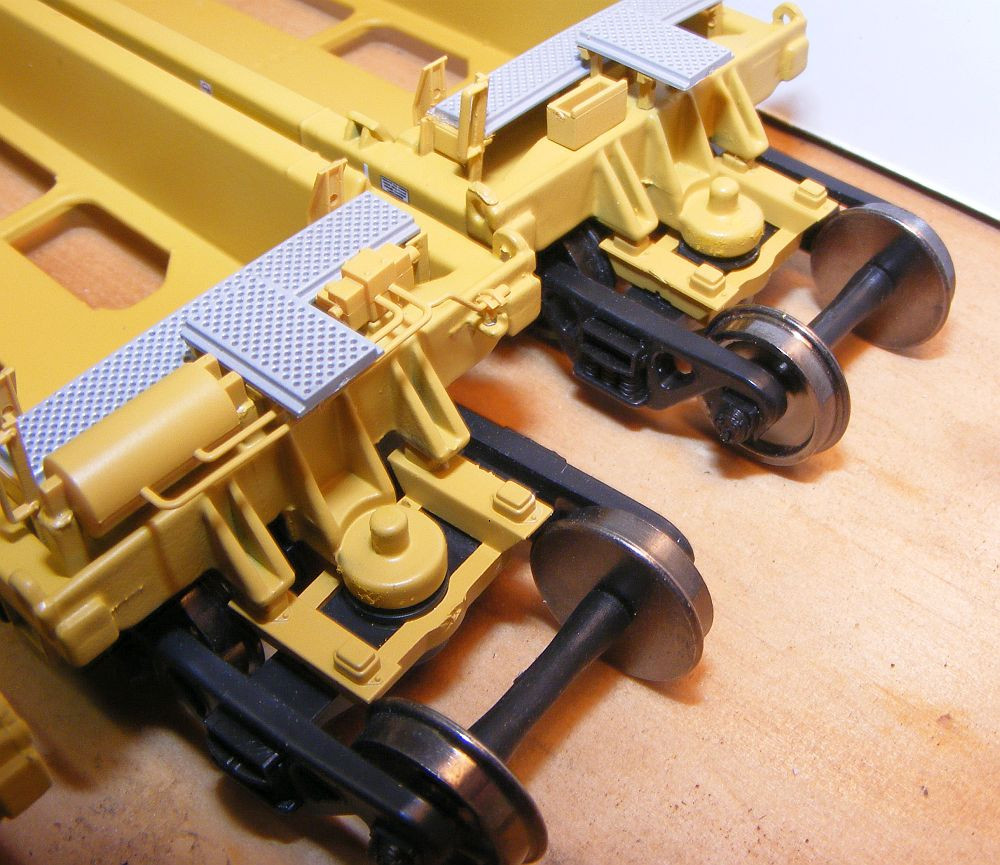

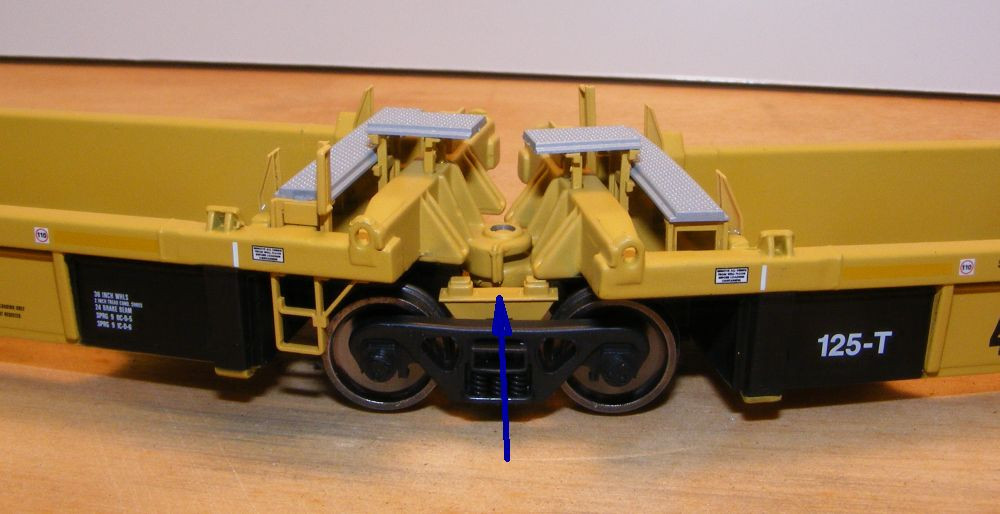

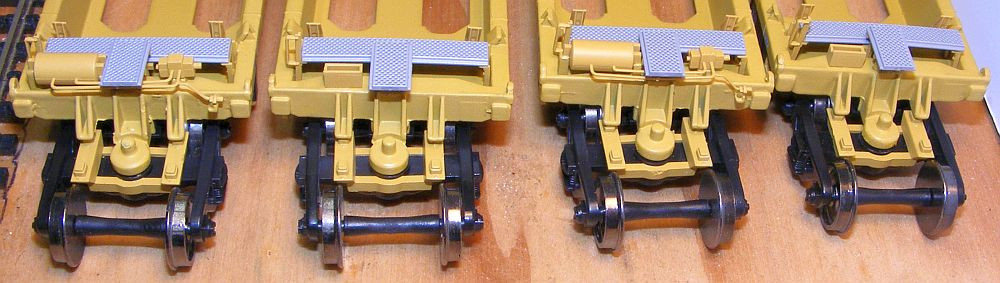

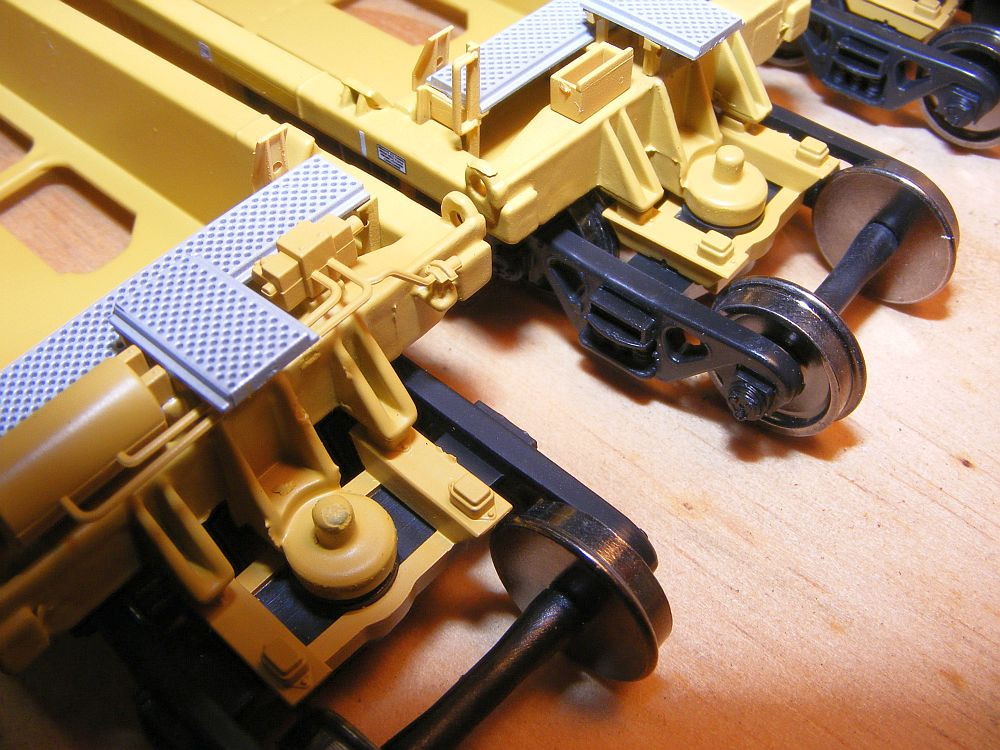

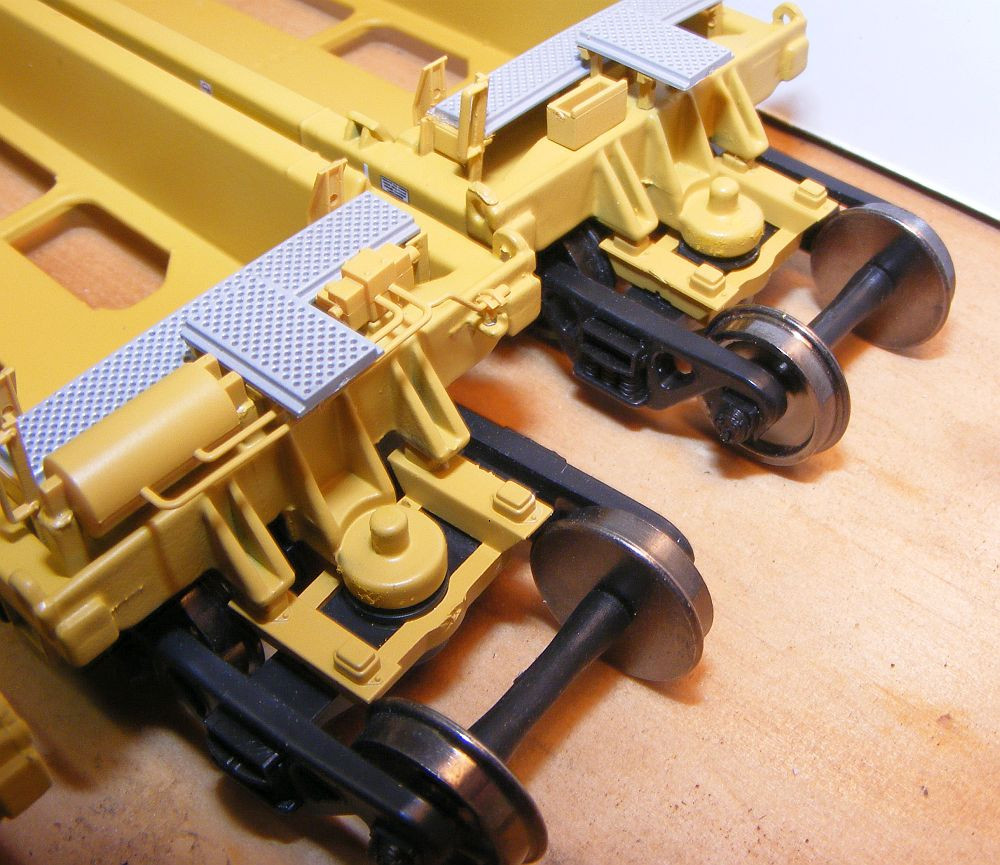

Some photos of that articulated truck arrangement from Athearn, then Walthers,...

Athearn

Walthers,..

What I am concerned with is the snugness of that fit in our model connections,...that might be contributing to my derail observations when backing these cars thru turnouts.

Athearn

Walthers,..

What I am concerned with is the snugness of that fit in our model connections,...that might be contributing to my derail observations when backing these cars thru turnouts.

When I look at the photo of the HO cars, I wonder how well the cars enable the classic "3 point suspension" that we use for non-articulated cars, where one truck is tightened so it only pivots, and the other is looser so it and the car can sway in slightly different directions.

For the articulated cars, the equivalent would be that the two joined cars would be able to sway somewhat independently of each other. Do the Athearn and Walthers joints allow that?

If not, it might make sense to slightly ease the joint - probably more the part of the upper connector that wraps around the lower connector, and not the hole in the upper connector itself. The trick here would be doing it so the cars stay connected, and each car is connected rigidly enough to one truck that it doesn't sway excessively.

Steve

Yes, Steve that was the first though that entered my mine. I began to try adjust the tightness of the trucks as a first experiment,...though I arrived at a solution, but subsequently discovered I had not solved everything.

What end of a single car does one allow the more loosely tightened truck? or does one look at the two car (or multiple car) arrangement to accomplish some sort of 3-point suspension?? (or a single car, or a pair, or 3, etc)?

That's when I began to take a closer look at the 'freedom of movements' at this articulation joint. Both the conical shaped base and the height of that central pin come into question. The conical base certainly allows for free swing movement, but if the 'upright pin' is too tall or too tight, the freedom of movement is definitely affected,...both bending wise between cars, and swaying/tipping wise.

Is the conical base really needed? The new ScaleTrain models doesn't seem to think so.

Is the fit around that vertical pin really need to be that firm, or is a more tolerate fit better??

Greg@mnrr

Section Hand

View attachment 133518

I replied,

That doesn't look like any of my model rr articulated container car joins ?

Thought I might find something here,...but can't interpret this yet

https://www.trackopedia.info/encyclopedia/railway-vehicles/types-of-bogies

I like how on the prototype, it appears that the wheel set and bearing on the right have been changed out.

-Greg

Am I looking at this correctly or not?

It does NOT appear to me that this connection between the 2 is centered on the centerline of the rail cars,...or even the center of that bolster truck??

https://modelrailroadforums.com/forum/index.php?attachments/1633481664185-png.133518/

It does NOT appear to me that this connection between the 2 is centered on the centerline of the rail cars,...or even the center of that bolster truck??

https://modelrailroadforums.com/forum/index.php?attachments/1633481664185-png.133518/

2 Long Car Experiments

Okay as I have admitted, the Peco guard rails across from the frogs do need to be shimmed. But I hesitate in some cases because I have some locos and a few cars with those larger 'pizza cutter wheels' that I wish to run on this layout. I will shim those that I find are really necessary, but I don't want to just blanket accuse the turnouts ONLY.

Lets look at several other situations. What if I want to run a few of these long cars (autoracks, extra capacity boxcars,...

They are close to the length of 2 of those 40 foot container cars. If I were to tighten up the truck screws on both ends of those long cars, I'd be willing to bet they would be really prone to derailing,...stiffness/rigid over that length between the trucks. It might even be even worst if I were to couple 2 of those long cars together while leaving their trucks in a firm tightness ( although the couplers between these 2 might allow some non-rigid compliance)

My point is those rigid long cars will derail very easily if all the trackwork is not PERFECTLY FLAT, regardless of the width of those flangeways. To reinforce my observations I then loosened up the screws on one end of those 2 long cars, and they both went thru that same Peco curved turnout with NO derailments,..both forward and rearward numerous times (and that Peco does not have any shims at this time).

Okay as I have admitted, the Peco guard rails across from the frogs do need to be shimmed. But I hesitate in some cases because I have some locos and a few cars with those larger 'pizza cutter wheels' that I wish to run on this layout. I will shim those that I find are really necessary, but I don't want to just blanket accuse the turnouts ONLY.

Lets look at several other situations. What if I want to run a few of these long cars (autoracks, extra capacity boxcars,...

They are close to the length of 2 of those 40 foot container cars. If I were to tighten up the truck screws on both ends of those long cars, I'd be willing to bet they would be really prone to derailing,...stiffness/rigid over that length between the trucks. It might even be even worst if I were to couple 2 of those long cars together while leaving their trucks in a firm tightness ( although the couplers between these 2 might allow some non-rigid compliance)

My point is those rigid long cars will derail very easily if all the trackwork is not PERFECTLY FLAT, regardless of the width of those flangeways. To reinforce my observations I then loosened up the screws on one end of those 2 long cars, and they both went thru that same Peco curved turnout with NO derailments,..both forward and rearward numerous times (and that Peco does not have any shims at this time).

CambriaArea51

Well-Known Member

I run long intermodal trains at out club that has Peco switches. All different brands of cars and sometimes with pushers with no derailments. I check the adjustment of the trucks of any new car I get to see if they are too loose or too tight.

Do you have some of these metal framed Wathers 40 foot container cars?

https://modelrailroadforums.com/for...r-car-tracking-derails-etc.33629/#post-505743

Can you back them thru a Peco curved turnout with no problems?

https://modelrailroadforums.com/for...r-car-tracking-derails-etc.33629/#post-505743

Can you back them thru a Peco curved turnout with no problems?

Articulated Autoracks

Experimenting with those 2 long cars made me think about those articulated autoracks I had. How would these articulated cars perform, …..and how might they differ from articulated container cars??I have 2 different Atlas models of these articulated car sets,...both very nice models.

These cars do have a different bolster truck design. I took them straight out of the new box and ran them thru my troublesome Peco curved switch with NO SHIMS. They worked beautifully,..no derails, very smooth operation.

I then try to bend them around their articulated joint,...and compare that with the container cars. Here you can see that there is more freedom of movement between the double cars of the autoracks verses the container cars,..

There was one articulation that caught my attention more than the others,....the relative twisting motion that would allow the cars to roll more in relation to one another. The autoracks were more supple than the container cars,...they could roll a bit more then the pretty stiff container cars. I caulked this up as a rigidness with the container car connection compared with the autoracks. Perhaps this more rigid nature was contributing to their derailing more easily?

My next experiment was to loosen up the every truck screw on metal container cars that had appeared to be extra rigid. SURPRISE, now they flowed thru that troublesome Peco with no derailments.

(not sure yet how it will effect their tippy-ness when loaded with double high containers?)

EDITED: articulation arrangement

Brian

Last edited:

Articulated Autoracks

Just wish to express how delighted I was with the running of these Atlas articulate autoracks, ....really nice, AND able to take relatively small radius track (at least 22" in my experiment). I just happened to have acquired 2+2 sets at a very good price a number of years ago at the Timonium train show.

I even spent considerable effort to make them fit thru some pretty tight spaces on my upper helix loop track where it reenters the train shed.

The other 2 sets are the Auto Max

BTW, 22' radius is the bare minimum

santafewillie

Same Ol' Buzzard

In regards to the container cars. I add weight to all of the containers that I put on the bottom. I use pennies and add 14¢ to each 40' container. That works out to 1.25 oz per container. In practice I only use 40' containers on the bottom of a well as that's what I usually see on the intermodal trains out of Alliance Yard north of Ft Worth. I do not add as much to longer containers which I put on top to avoid making the load top-heavy. 20' containers get seven pennies each as I only see short containers on the bottom, mostly. The extra weight so low down in the well cars sure makes a difference in tracking.

Disclaimer: I do not have an intermodal yard and only run my well cars (64 total) back and forth between staging yards, primarily on the main, 30"-32" radius minimum, or occasionally the passing sidings of 26"-30" radius. I do sometimes back them into passing sidings through Atlas #6 switches without incident.

Disclaimer: I do not have an intermodal yard and only run my well cars (64 total) back and forth between staging yards, primarily on the main, 30"-32" radius minimum, or occasionally the passing sidings of 26"-30" radius. I do sometimes back them into passing sidings through Atlas #6 switches without incident.

Most of my problems with those Walther's 40 footers occurred when backing them thru Peco 3-ways and Peco curved (double curved) turnouts. The Peco 3-ways are rated as 24" radius on their diverging routes.

https://modelrailroadforums.com/forum/index.php?threads/container-car-tracking-derails-etc.33629/

I had also hoped to run these cars (and lots of others ) into sidings and loading rails of my dock shipping scenes both on the top deck (Calif) and the bottom deck (Balt).

I had hoped that the metal frame of those cars was enough to make them run unloaded at times.

https://modelrailroadforums.com/forum/index.php?threads/container-car-tracking-derails-etc.33629/

I had also hoped to run these cars (and lots of others ) into sidings and loading rails of my dock shipping scenes both on the top deck (Calif) and the bottom deck (Balt).

I had hoped that the metal frame of those cars was enough to make them run unloaded at times.

...from another forum. When I look at the photo of the HO cars, I wonder how well the cars enable the classic "3 point suspension" that we use for non-articulated cars, where one truck is tightened so it only pivots, and the other is looser so it and the car can sway in slightly different directions.

For the articulated cars, the equivalent would be that the two joined cars would be able to sway somewhat independently of each other. Do the Athearn and Walthers joints allow that?

If not, it might make sense to slightly ease the joint - probably more the part of the upper connector that wraps around the lower connector, and not the hole in the upper connector itself. The trick here would be doing it so the cars stay connected, and each car is connected rigidly enough to one truck that it doesn't sway excessively.

Steve

3-point suspension

Yes, Steve that was the first though that entered my mine. I began to try adjust the tightness of the trucks as a first experiment,...though I arrived at a solution, but subsequently discovered I had not solved everything.What end of a single car does one allow the more loosely tightened truck? or does one look at the two car (or multiple car) arrangement to accomplish some sort of 3-point suspension??

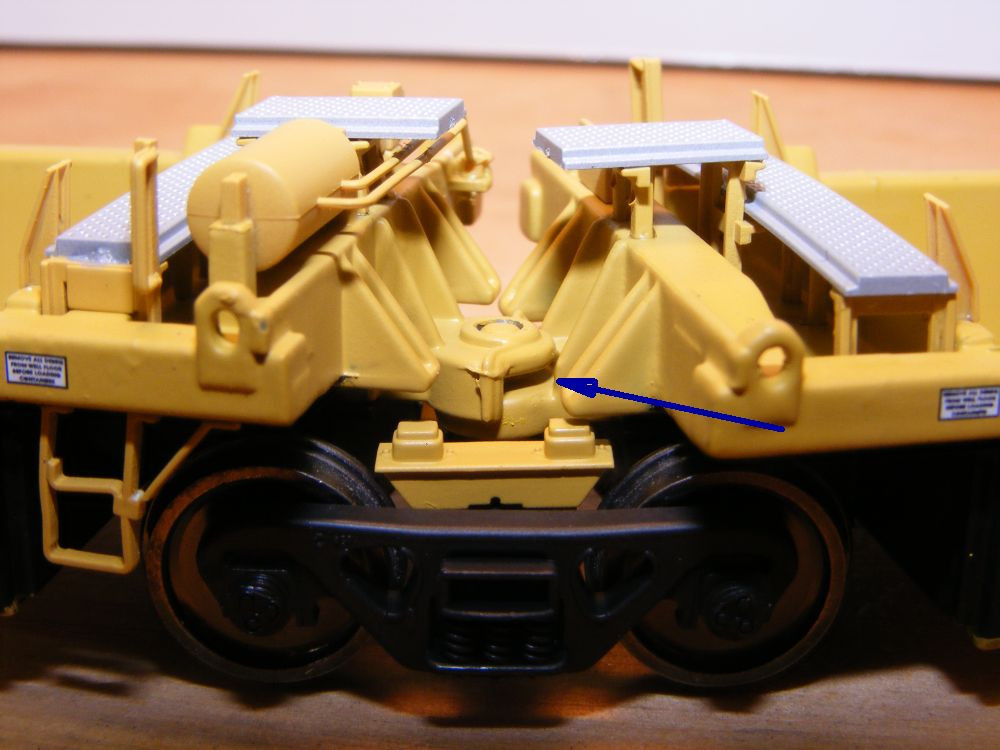

That's when I began to take a closer look at the 'freedom of movements' at this articulation joint. Both the conical shaped base and the height of that central pin come into question. The conical base certainly allows for free swing movement, but if the 'upright pin' is too tall or too tight, the freedom of movement is definitely affected,...both bending wise between cars, and swaying/tipping wise.

Is the conical base really needed? The new ScaleTrain models doesn't seem to think so.

Is the fit around that vertical pin really need to be that firm, or is a more tolerate fit better??

Brian

CambriaArea51

Well-Known Member

I have the Walthers 40', the Kato 53', and Athearn 57" spine cars to name a few. The Kato are plastic and metal.Do you have some of these metal framed Wathers 40 foot container cars?

https://modelrailroadforums.com/for...r-car-tracking-derails-etc.33629/#post-505743

Can you back them thru a Peco curved turnout with no problems?

In regards to the container cars. I add weight to all of the containers that I put on the bottom. I use pennies and add 14¢ to each 40' container. That works out to 1.25 oz per container. In practice I only use 40' containers on the bottom of a well as that's what I usually see on the intermodal trains out of Alliance Yard north of Ft Worth. I do not add as much to longer containers which I put on top to avoid making the load top-heavy. 20' containers get seven pennies each as I only see short containers on the bottom, mostly. The extra weight so low down in the well cars sure makes a difference in tracking.

Disclaimer: I do not have an intermodal yard and only run my well cars (64 total) back and forth between staging yards, primarily on the main, 30"-32" radius minimum, or occasionally the passing sidings of 26"-30" radius. I do sometimes back them into passing sidings through Atlas #6 switches without incident.

I'd be interested in exactly how do you add those pennies to your containers?

These Walthers metal framed cars seem to have enough weight to travel unloaded,...but what about those many other plastic cars?

One thought goes to adding the weight to the bottom container. But many of those containers are closed plastic boxes that have no seam to open up to put in weights. Just wondering what other solutions have been tried with adding weight to those containers themselves??

Last edited:

I opened up another set of these Walther's 40' footers this afternoon, and discovered I could not even couple the cars together properly. The pin-and-hole coupling is just NOT correct. The car with the hole does not sit all the way down on the pin of the other car. In several cases the connection is so bad as to raise the other end of the car up in the air, with no possibility of making a connection to the next car !!!

So here are some photos of several of the cars 'coupled together' with the one car raised in the air as a result of that 'pin & hole' situation,..

And a few close ups that show the 'not seated properly' condition if both cars are sitting level,..

I looked closely at the 'pins', and it does appear they are a little heavily coated with paint,...but I dare not try to cut or file this heavy paint off?

But rather I think reaming out the hole is a better idea??....and hopefully that will not increase the tendency for increased car rocker side- to- side when loaded with 2 containers?

BTW, I'm surprised I have not found more negative discussions about such a problem??

So here are some photos of several of the cars 'coupled together' with the one car raised in the air as a result of that 'pin & hole' situation,..

And a few close ups that show the 'not seated properly' condition if both cars are sitting level,..

I looked closely at the 'pins', and it does appear they are a little heavily coated with paint,...but I dare not try to cut or file this heavy paint off?

But rather I think reaming out the hole is a better idea??....and hopefully that will not increase the tendency for increased car rocker side- to- side when loaded with 2 containers?

BTW, I'm surprised I have not found more negative discussions about such a problem??

santafewillie

Same Ol' Buzzard

Several questions here that I will try to answer. Regarding the pennies inside the containers, I just take the containers apart and glue the pennies inside using Walther's Goo, or sometimes I use Gorilla Super Glue. I prefer the Goo, but went with the Super Glue when my tube of Goo hardened up. I am going out of town today, so I will take pictures tomorrow and post them. Trains are in the train shed more than 120' away and I just don't have time this morning. Many of my containers predate when they came already glued together from the manufacturer. Most of mine are Athearn or Walther's, but I think that I have a few other manufacturers as well, Bowser and A Line come to mind.

Regarding the Walther's metal cars. I have a few but it doesn't matter, I weight all containers regardless. However their freight cars consistently have the same poor quality as their structures and everything else with their name on it. I ream out the holes and I have also been known to add a drop of LaBelle #108 oil to the pins. I have found that the looser holes generally lead to better tracking anyway.

Regarding the swaying. Unless it is too extreme, I just let it happen. I have seen many on the BNSF line coming out of Alliance Yard on their way up the main line towards Oklahoma City, that sway. Not a lot, but it is noticeable. If I can't fix a car, I just limit it to only one container (or two 20') on the bottom. I see plenty of examples of only single height containers on that line. It's due to the weight.

As I posted in post #12, I don't switch my well cars anywhere except the staging yards, and that isn't very often. I do switch up the container mix often though. I do back them up occasionally through switches without incident. True modern container yards require too much distance on a model railroad layout. It can be done as Ken (D&J Railroad) is able to devote the proper amount of space for a modern yard.

Regarding the Walther's metal cars. I have a few but it doesn't matter, I weight all containers regardless. However their freight cars consistently have the same poor quality as their structures and everything else with their name on it. I ream out the holes and I have also been known to add a drop of LaBelle #108 oil to the pins. I have found that the looser holes generally lead to better tracking anyway.

Regarding the swaying. Unless it is too extreme, I just let it happen. I have seen many on the BNSF line coming out of Alliance Yard on their way up the main line towards Oklahoma City, that sway. Not a lot, but it is noticeable. If I can't fix a car, I just limit it to only one container (or two 20') on the bottom. I see plenty of examples of only single height containers on that line. It's due to the weight.

As I posted in post #12, I don't switch my well cars anywhere except the staging yards, and that isn't very often. I do switch up the container mix often though. I do back them up occasionally through switches without incident. True modern container yards require too much distance on a model railroad layout. It can be done as Ken (D&J Railroad) is able to devote the proper amount of space for a modern yard.

ctclibby

Well-Known Member

rgeiter: If you have Gunderson types with the high ends, let me know. My era is pre 74 so the newer ones would not work.I’m going to get rid of all my intermodal stuff since I don’t use them anymore. They’ve been stored for so long and moved around so much that most of the cars are damaged or missing parts. Maybe I’ll see if anyone here wants them.

Later

Affiliate Disclosure: We may receive a commision from some of the links and ads shown on this website (Learn More Here)