A friend gave me Ragg's... to Riches: the Aladdin General Store kit in O sacale to build for him. This is my first O scale build and being in HO the size difference takes some getting used to

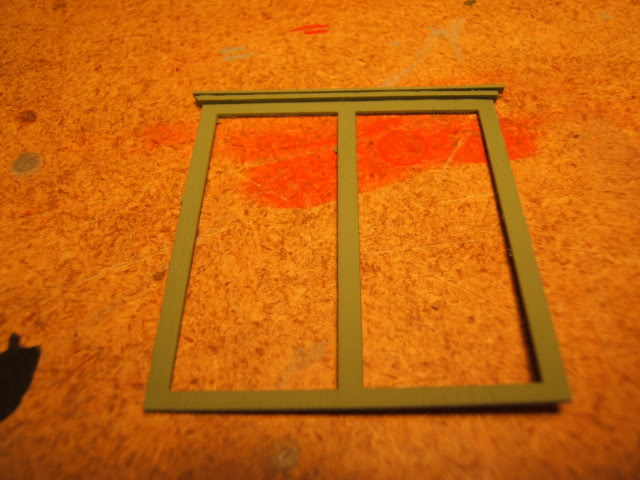

This is a straight from the instructions build with minimal weathering. I'm painting the building white with a faded green trim and window frames. The first thing to build is the window frames, adding the crown molding.

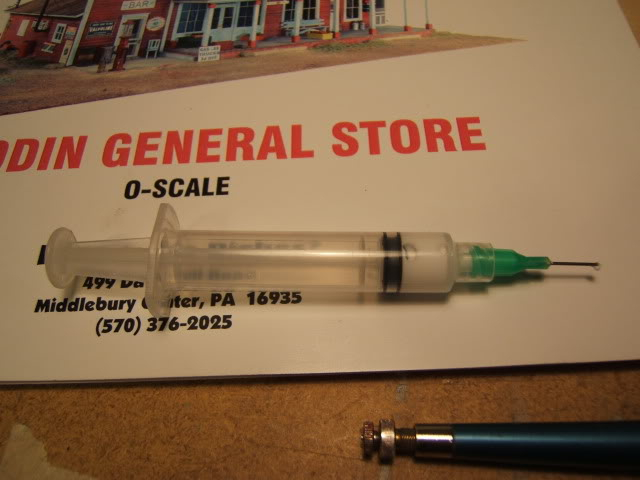

Raggs to riches supplies you with a sringe for the glue. i was skeptical about using it at first but the glue appilcation control you have using it is definetly an improvment over my former toothpick method.

After the glue set I primed and painted the frames

This is a straight from the instructions build with minimal weathering. I'm painting the building white with a faded green trim and window frames. The first thing to build is the window frames, adding the crown molding.

Raggs to riches supplies you with a sringe for the glue. i was skeptical about using it at first but the glue appilcation control you have using it is definetly an improvment over my former toothpick method.

After the glue set I primed and painted the frames