MikeGTW

Signalman, ESQ

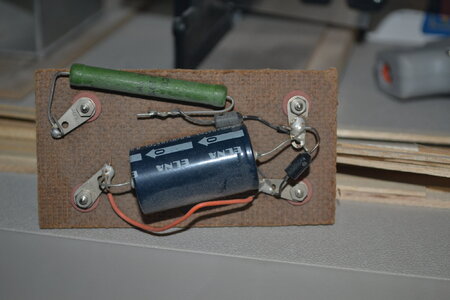

I've known about them for IDK 30 or 40 years just made my own I'm pretty sure the've been sold here I have an old book for electronic prjects for model rr's from 1974 it has a scematic for one in itOh OK. The CDU Tony has will power at least 12 switches at the same time, but I'm curious, you obviously know about CDU's, is there a reason they aren't used in the US, as Tony said, he couldn't find any, and I looked and couldn't find any either, are these some kind of specialist equipment not generally known about in the US since they are so hard to find?

And I did look around for any being sold here none so far OOPS found one at Model train stuff a peco unit $32.99