You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help identify these reefers?

- Thread starter beiland

- Start date

ModelRailroadForums.com is a free Model Railroad Discussion Forum and photo gallery. We cover all scales and sizes of model railroads. Online since 2002, it's one of the oldest and largest model railroad forums on the web. Whether you're a master model railroader or just getting started, you'll find something of interest here.

A razor saw to cut the floor off?

Here is a photo of some on the Santa Fe Grand Canyon Limited in San Bernadino. In this case strawberries headed east.

And another with three reefers immediately behind the locos, from a year later

Perhaps my posting was confusing here? I will be cutting that original chassis in half and lengthening it so those coupler mounts will now be at the end of the car. I'll likely use 2 stiff lengths of steel, on edge, along either side of the motor to regain the stiffness of the cut chassis, .....then attach some lead weights to increase it's traction power,...something like this..

Affiliate Disclosure: We may receive a commision from some of the links and ads shown on this website (Learn More Here)

Iron Horseman

Well-Known Member

Interesting. I suppose I should have guessed that as all their passenger cars have the tops coming off.I discovered the problem. The Walthers cars do NOT separated down at floor level,...but rather their tops come off. That nixes them as candidates for a pusher loco project I have in mind.

A razor saw to cut the floor off?

I do realize that about the passenger cars, but never suspected to about this freight carInteresting. I suppose I should have guessed that as all their passenger cars have the tops coming off.

I would want to ruin these cars by doing that. rather i have found that Athearn built very similar car with removable bottomsA razor saw to cut the floor off?

Iron Horseman

Well-Known Member

It isn't really classified as a freight car. It is an express reefer so called a "head end car" because it would normally be run at the head end of a passenger train. Notice it does not have standard freight trucks, but rather high speed passenger type trucks.I do realize that about the passenger cars, but never suspected to about this freight car

Here is a photo of some on the Santa Fe Grand Canyon Limited in San Bernadino. In this case strawberries headed east.

And another with three reefers immediately behind the locos, from a year later

Last edited:

Not with those trucks and wheelsets. Walthers.Turns out they are apparently just Athearn cars...who knew.

Iron Horseman

Well-Known Member

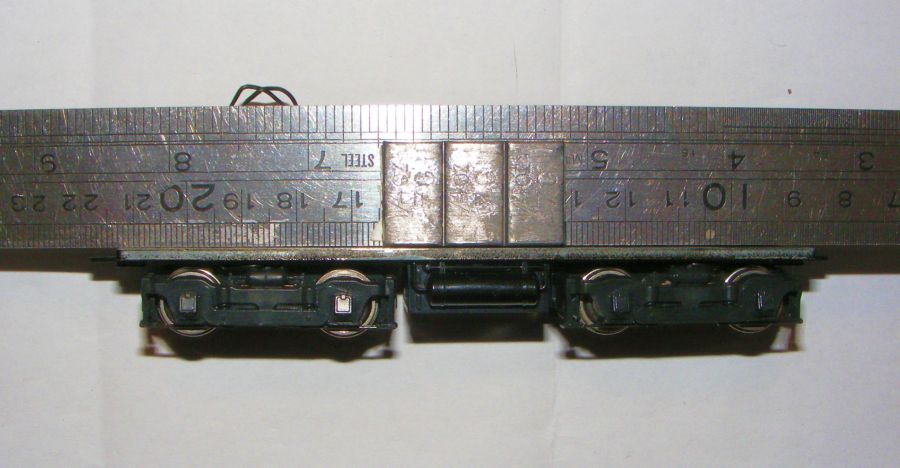

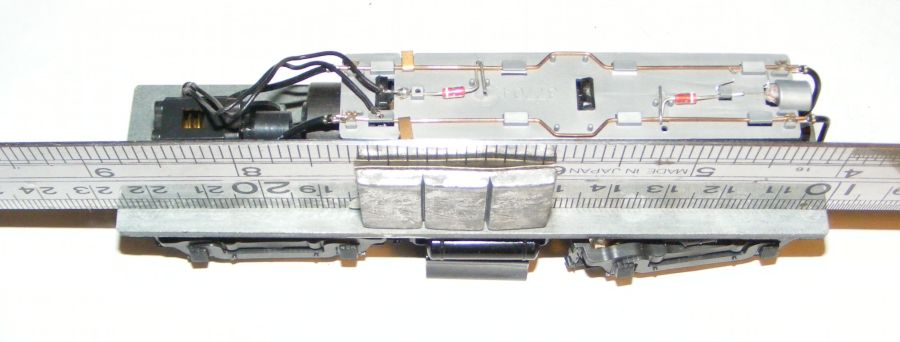

The short chassis will have coupler issues. A body mount at the end will not work as pictured because the end of the car will swing out really far on curves and the couplers will not be able to handle the difference. You would have to find some way to make a really long shank swinging arm coupler (on the order of Lionel) to reach from the x-switcher coupler pocket to the end of the car. OR if you could find a way to stretch the chassis, those Alco wheels look pretty good under that car.Here are a few photos of some plans I have to fit 2 different size Kato powered chassis into those athearn cars.

View attachment 139660

BigGRacing

Aka. Gary Russell

Hey Beiland, I see ConCor on one of the chassis, is that a Kato brand by chance?Kato powered chassis

Yes they are older ConCor models with the power system supplied by KatoHey Beiland, I see ConCor on one of the chassis, is that a Kato brand by chance?

The short chassis will have coupler issues. A body mount at the end will not work as pictured because the end of the car will swing out really far on curves and the couplers will not be able to handle the difference. You would have to find some way to make a really long shank swinging arm coupler (on the order of Lionel) to reach from the x-switcher coupler pocket to the end of the car. OR if you could find a way to stretch the chassis, those Alco wheels look pretty good under that car.

Perhaps my posting was confusing here? I will be cutting that original chassis in half and lengthening it so those coupler mounts will now be at the end of the car. I'll likely use 2 stiff lengths of steel, on edge, along either side of the motor to regain the stiffness of the cut chassis, .....then attach some lead weights to increase it's traction power,...something like this..

Last edited:

Iron Horseman

Well-Known Member

Perfect.Perhaps my posting was confusing here? I will be cutting that original chassis in half and lengthening it so those coupler mounts will now be at the end of the car.

Just a few re-thoughts on that 'frame stiffener'. Any frame stiffener would likely need to be 'permanently' adhered to those existing frame plates at either end. But they need to provide access to the motor, drive shafts, etc,so likely something like that steel rule on edge would NOT be appropriate. Have to come up with another idea?

Affiliate Disclosure: We may receive a commision from some of the links and ads shown on this website (Learn More Here)