When installing one of these turnout actuators, I make only one measurement. Everything else is easily done by eye. With practice, you can install one in 10-15 minutes. The actuators are installed after the turnouts are in place on your layout. No jigs are required. Use 1/16" brass tubing and 0.032" music wire (also known as piano wire).

Steps are as follows.

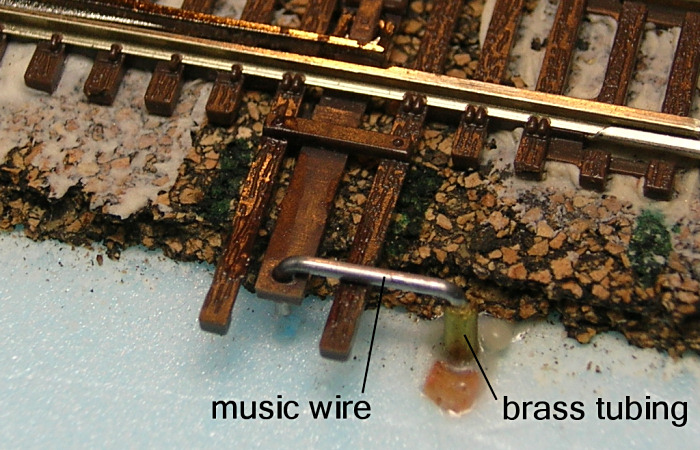

1. Select a location for the brass tubing, as shown in my photo above. I use a location that is 3/8" from the turnout throwbar. This is the only step where I measure anything, but even here extreme precision is not necessary. A little more or less than 3/8" is fine.

2. Drill a hole for the brass tubing. If you are installing through several inches of plywood and foam, you'll need an extra long 1/16" drill bit. I found mine at a big home center (Lowe's). But you can also purchase "aircraft" or "long boy" drill bits online.

3. Insert a long piece of brass tubing into the hole from the top of the layout. At this point, you have not cut the tubing to length, so you may be using a piece of tubing that is 2 or 3 feet long. Push until about 1" of tubing protrudes from the underside of the layout. On the top of the layout, mark the tubing where it emerges above layout. Now pull the marked tubing out of the layout and use a razor saw to cut it to length approximately 1/8" above your mark. De-burr the opening of the tubing so the music wire can slide in freely. I used a dull Xacto blade for de-burring.

4. Re-insert the cut piece of brass tubing until only about 1/8" extends above the top of the layout. Friction is probably enough to hold the tubing in place, but I use a dot of glue to be sure.

5. Cut a piece of music wire that is several inches longer than will be needed for the particular location. You'll trim it later. Music wire is cheap so be generous.

Hint: Do not attempt to cut music wire with the little wire cutter you use for cutting hookup wire; you will ruin your wire cutter. Use the cutter built into needlenose pliers, or better yet, a heavy diagonal cutter or a pair of linesman's pliers. Music wire is

tough stuff.

6. Make right angle bend approximately 3/4" (no need for precision here) from one end and drop the wire into the tubing from the top on the layout (the bend keeps it from falling through).

7. With the wire inserted in the tubing, lay the bent portion of the music wire across the throwbar and note the location of the hole in the throwbar. Use two needlenose pliers to grip the wire and make a small downward bend so that the end of the wire can drop into the hole in the throwbar. If the downward bend is too long, trim off the excess. This is all done by eye without measuring anything.

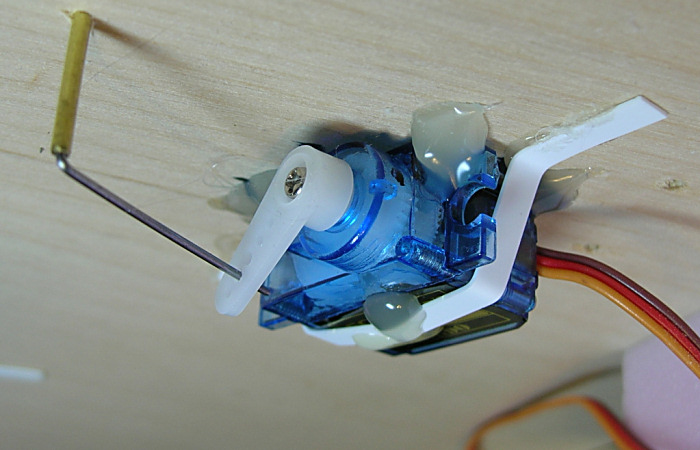

8. On the underside of the layout, you'll have at least a couple of inches of music wire extending out of the tubing. Eventually, you will bend this at a right angle just where it emerges from the tubing then trim it to a convenient length. However, you don't want to bend it or trim it until you determine the location of the turnout motor, be it a Tortoise, a servo, or some other type of motor. I happen to use servos. The music wire can be bent in any convenient direction so you have a lot of freedom in where you mount the turnout motor.

For electronics, I use the

Tam Valley Depot system with servos. The costs work out to be about the same as using Tortoises. But the cost of the Tam Valley system includes everything: both pushbutton control and DCC control, a pushbutton switch and LED indicators for your control panel, and relays for switching frog polarity. If you don't want frog switching, you can save about $3 per turnout. By the way, the Tam Valley system can drive Tortoises, too, with an optional add-on board.

If you have any other questions, I will try to answer them.

- Jeff