Bristolman2012

Active Member

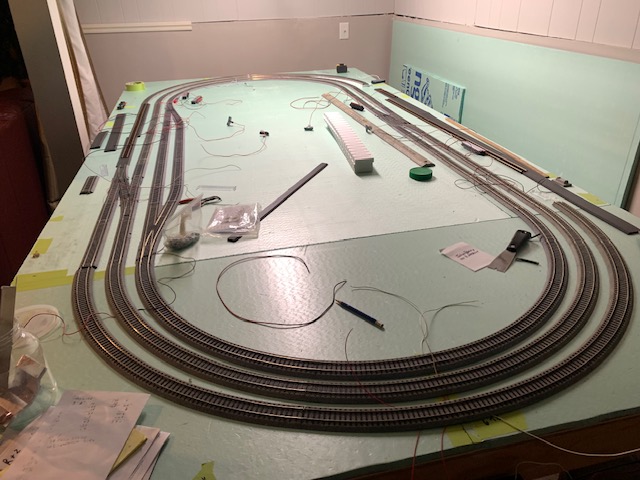

Have my layout ( kinda ) figured out . If wiring guru could help it would be appreciated . The passing siding has the insulated uni joiners on all 8 legs ( turnouts ) as I am adding switch motors to them . The siding is powered . The outside track on rt side will have 2 single truss bridges with maybe spacing between them . I’m using kato in curves and then using all code 83 track for bridges and track till next kato curves .

Mike

Mike