I've been taking these pictures (and a couple of videos) with a Kodak Easy Share Z91 camera. It does OK for what it is, but I've been wanting to get a better camera for some time now. I got a bonus at work earlier this month, and decided to put the money towards a new camera. I wanted a DSLR (digital single lens reflex) that could also record video.

I'd had my eye on a Canon EOS Rebel T7 that I could buy new locally for $399. Canon makes good cameras, and their EF mount lenses are good quality and plentiful. The downside is that the T7 isn't all that great for video, autofocus doesn't work in video mode (at least that's what I read), and it does not have an input for an external microphone.

I spotted a Nikon D3500 on eBay for $450, but the D3500 didn't really have the features I would have liked, either. So I made it a matter of prayer, because that's who I am and I don't apologize for it, asking God to lead me to the camera I should get.

Monday morning I was watching YouTube and a video came up in my list that looked interesting, so I watched it. A man and his wife were challenged by a viewer to come up with a budget camera outfit for each of them, and see who's outfit took the best pictures and videos. The couple utilized a website for a used photo equipment dealer, keh.com, so I checked out the website, looked at a lot of reviews from different places, and found them to be a reputable company.

So off to

https://www.keh.com/ I went. I looked at a number of different cameras, and decided on a Nikon D7000 body which they had graded as EX+, their highest rating. I also bought a Nikon 35-80mm lens graded EX. EX stands for excellent, btw. The YouTuber's have a discount code on their channel, so I used that and got 5% off. I splurged and paid for overnight shipping.

Ordered it Monday morning, the package got here Tuesday morning. FedEx actually came through, for once!

Here's the box, opened but not unpacked:

And the goodies:

That little white spot on the lens cap is the only blemish on this outfit, other than some VERY light scuff marks on the bottom. The battery and charger were included, but I had to buy a USB cable to transfer pics from the camera to the computer.

I could tell this camera had barely been used. It, and the lens, are in pristine condition. It could easily pass for new.

On a digital camera, the shutter has a limited lifespan before it starts to fail and not always open or close completely. Generally, the shutter is good for around 200,000 cycles before it starts to have issues, but that number is just a generality. Another YouTuber made a video detailing how you go about finding what the current shutter count is. Basically, you take a photo and upload it to a website, in this case

https://www.camerashuttercount.com/, and they will 'decode' the info on the photo and give you the current shutter count.

Mine came out to be

One thousand nine hundred fifty six! 1% of this models expected shutter life! As I suspected, this camera has barely been used! That shutter will probably outlive me!

How much did all this cost me? Purchase price, discount, tax, and shipping came out to $349.12! I think I got a good deal! Thanks, God!

It did not come with a manual, but I found it on Nikon's website for download. I was also pleased to discover that a "For Dummies" manual has been written for this camera. I have one coming from Washington state. For those not familiar with them, the "For Dummies" series of books

https://www.dummies.com/ takes a subject and breaks it down into plain, easy to understand concepts and language. Perfect for simpletons like me! I also ordered a couple of screen protectors for the LCD screen on the back of the camera. I got the clear acrylic style that snap on to the body, rather than the plain sheet style like we use on our cell phones.

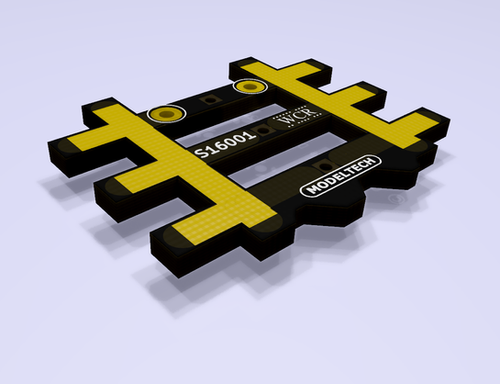

I plan to use this camera to take photos (and hopefully more videos) of my layout and projects. It's going to take some time to learn the features of this camera, though. I used to own a Minolta X700, and have really missed having an SLR with interchangeable lenses. I've wanted a DSLR for a long time, now I have one!

Let the fun begin!