videobruce

Tower Operator

Details;

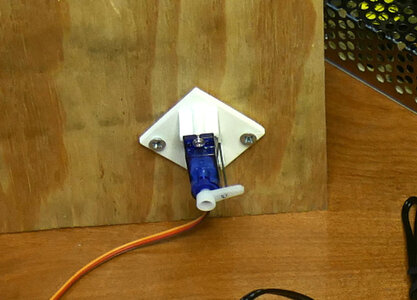

N scale, Peco electrofrog turnouts (around 57 yard & main), Motrak servo mounts, SG90 type servos, 3/8" plywood, 1/2 foam board, cork roadbed. Holes drilled under the throw rods, but they maybe too small and all are not 'dead center'.

The only two ways I can think of are screws or hot glue, both with substantial disadvantages;

Screws; they need to be drilled first after marking the EXACT location of the holes. Self taping screws don't make holes in plywood w/o a lot of pressure which will not work here.

Hot glue; concerned about when it oozes out and/or gets on your fingers and sliding the mount around to position it.

I tried looking around for small self drilling screws, but couldn't find anything. My concern for the hot glue other then above is the setup time after you apply the glue to the underside of the mount and tiring to line up the piano wire thru the hole on the base AND the hole on the 'horn'.

I also thought about double stick tape, but I can't see it sticking to typical rough surface plywood.

N scale, Peco electrofrog turnouts (around 57 yard & main), Motrak servo mounts, SG90 type servos, 3/8" plywood, 1/2 foam board, cork roadbed. Holes drilled under the throw rods, but they maybe too small and all are not 'dead center'.

The only two ways I can think of are screws or hot glue, both with substantial disadvantages;

Screws; they need to be drilled first after marking the EXACT location of the holes. Self taping screws don't make holes in plywood w/o a lot of pressure which will not work here.

Hot glue; concerned about when it oozes out and/or gets on your fingers and sliding the mount around to position it.

I tried looking around for small self drilling screws, but couldn't find anything. My concern for the hot glue other then above is the setup time after you apply the glue to the underside of the mount and tiring to line up the piano wire thru the hole on the base AND the hole on the 'horn'.

I also thought about double stick tape, but I can't see it sticking to typical rough surface plywood.