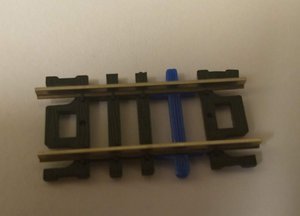

Hi, I think this has happened to most of us. Especially if we are soldering track directly. I took some quick measurements with a vernier caliper and drew the tie in FreeCAD. And this is the result.

This isn't perfect, the track doesn't actually slide into the tie at all, but it's the right height and the right width. I can probably just glue the tie to the neighboring ones with acetone. And if I print it with wood impregnated filament, I could even finish it off as if it's wood. But, I think the effect here is actually pretty good, and certainly a lot less of a pain than trying to solder wires to the track without melting any ties.

I'll probably post the design to thingiverse when I've got the track attachment figured out. That's just rather challenging to measure and draw.

This isn't perfect, the track doesn't actually slide into the tie at all, but it's the right height and the right width. I can probably just glue the tie to the neighboring ones with acetone. And if I print it with wood impregnated filament, I could even finish it off as if it's wood. But, I think the effect here is actually pretty good, and certainly a lot less of a pain than trying to solder wires to the track without melting any ties.

I'll probably post the design to thingiverse when I've got the track attachment figured out. That's just rather challenging to measure and draw.