Thanks, I had the feeling I didn't have that quite right. I was thinking about it sending power to where the train would go, but in retrospect that wouldn't make much sense for a definition. It's going both ways as the train does have the potential to travel the wrong way into a turnout on my layout.You are confused on the terms. When the power flows through both routes of the turnout all the time is it NOT power routing. Power routing is when the power only goes down the path the turnout is switched to. The other track would be electrically dead because both rails would be the same polarity.

This is why my original recommendation was simply two wires to the track.

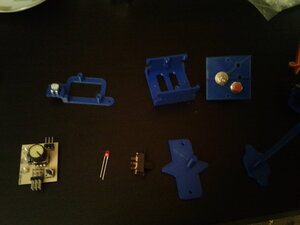

As you can see from the picture, I opted to take your advice and it seems to be working as expected.

Definitely, it's somewhat more complicated than doing a single tie, but once I've got a decent tie that can slot into the track, making several that cover a curve is mostly a matter of giving the appropriate arcs to the inner and outer spacers.Can your printer make up 5 ties on a curve to fill that gap?

I wound up removing 5 ties because of the way that I did it previously, I screwed up a couple of the ones on either side and they weren't at the same location to begin with. It was either take the 5 or risk ruining a new section of track. I think I made the right call, but in general, it would have been better to remove fewer ties.

The main limitation once you've got a design that can do the spacers and a tie is the build volume. Mine has a volume of 230mm by 230mm by 250mm, so, 5 ties is mostly a matter of getting the correct arc difference between the inner and outer spacers. Theoretically, I could do probably 45 degrees at a time. I think that's right, I'm too tired and lazy to do the math right now.

Designwise, This is still in development, right now I've got a tie that can slot into the top of a track, which may eventually be useful for maintaining appropriate track separation for laying flexible track. I'll likely keep a copy of that design and widen the slot in order to accommodate the bottom of the track.