From what I read

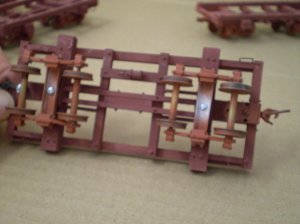

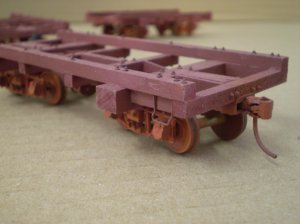

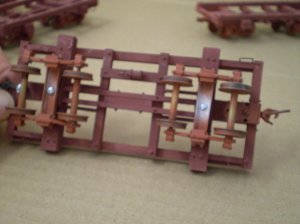

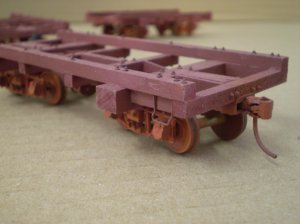

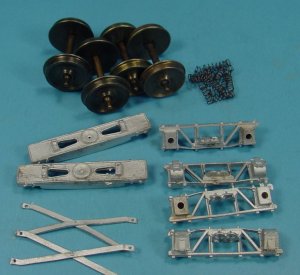

Sherrel, On3 is .75" - 19.05mm gauge and On30 is HO - 16.5mm. The ON3 is regarded as representing prototype 36" gauge, whereas On30 represents 30" gauge on HO track, and sometimes used for other gauges close to that. I don't know if there are any manufacturers of the .75" track, so possibly anyone doing that would hand lay it. They both follow the Scale of "O" = 1:48 which explains why the rolling stock is of the same size. Can't tell from your pic whether the axle ends are pointed or squared off (plain), but as the axles don't have rotating bearing caps, which is the usual reason for having plain ends (axles pass through the truck bearings), it would be reasonably safe to assume them to be pointed. The fact that those ends of the axles that can be seen on that left truck, also are slimmer in diameter than the axle between the wheels, indicates that they are either Intermountain, or Reboxx. The IM's, I don't think offer different lengths as far as I know, but Reboxx does.

I reposted my post from the Coffee Shop to here to keep the continuity going. Just to comment on whether you could squeeze them together. As it's not the axle length that needs shortening, it will depend on how the wheels are mounted on the axles. As I noted the ends appear to be slimmer than the center part. As it's the wheels that need to move inwards (and even distances) it would depend if the holes in the wheels match that smaller diameter, AND if the wheels are currently resting against the thicker center part (as a stop) to pre-set their gauge to On3. If the wheel center holes are the same diameter as the main axle and those axle tips are part of the whole axle i.e. the axle is one piece point to point, then it may be possible to move the wheels inwards along the shafts by pushing and rotating them to the smaller HO gauge. I believe that some of this type of axle/wheel, larger inner, smaller tip, actually have the tips/points as part of the wheel and the center axle is separate again. Walthers uses this system on some of it's wheel sets, where the metal wheel and tip are 1 piece metal, and the center axle is plastic to give each side electrical isolation. In this arrangement the wheels, which have a recess in the wheel's back that matches the axle size and press onto those plastic axles until they stop, once again setting the gauge. I believe this is also the method used by IM and Reboxx, only with metal axles and insulators in the wheels. A note on Reboxx here, they have sets where both wheels on an axle are insulated in this way, rendering the metal axle inert, and others with only 1 wheel insulated. Probably so the axle can have pickup wipers contacting the live axle and by swapping them end for end in a truck, pick up current from opposite tracks.