OgreMike

Active Member

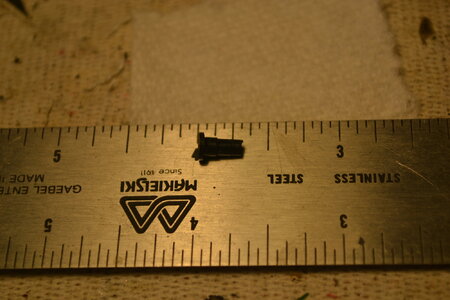

Hello all! I'm just getting back into Model RR'ing after a long hiatus and currently building my first ever home layout (The Oregon Pass Lines from the Atlas King Size Layout book). I'm also building my rolling stock, as most of what I'd accumulated in prior years had to be sold off during a very itinerant career in the military. Anyway, I recently purchased an HO DC/DCC Proto 2000 Series E7A/A consist in the Burlington colors, and I'm astounded with the detail and the sounds it can make, including the startup and shutdown regimen. Makes one feel like a real train engineer! One slight problem with the 2nd unit, however . . . upon carefully pulling the chasis out of its styrofoam encasement, the rear coupler on the unit fell out of its moorings (the round shank hole that secures it to the chasis with a drop-in linch pin) and luckily, I caught the coupler assembly before it could hit the ground. The coupler, itself, is completely assembled, including the box unit with the small black screw on the underside. But the LINCH PIN (if that's the correct term for it?) is missing. I searched everywhere in the box, but no luck. So I looked at the accompanying paperwork and I called Walthers warranty and parts number. The young lady there was nice, but she told me it'll be a few days before anyone can get back to me from their parts department as they're "way behind". So with that, I can't couple the units together and do a CONSIST which is one of the prime reasons for buying both units in the first place. I'm trying to build a Denver Zephyr prototypical passenger train, and these two units are going to head it up. However, without the ability to couple, I'm stuck (for now). So, do any of you know if there's a parts supplier out there who sells this particular type of linch pin? I've tried briefly to do searches at Yankee Dabler, MW Model Railroads, and Tony's Trains, but the search ends up with thousands of hits. I even went to the Walther's website and typed in the coupler assembly part number (which includes the linch pin), and the search on THEIR site, using THEIR PART NUMBER comes up empty. Anyone with any help on this, I'd be very appreciative! Right now, I'm considering some sort of home made rigging using perhaps a cut-off nail of the proper diameter to fit in the shank snugly.

Thanks, Mike

Thanks, Mike