Laird Knapp

New Member

I am a first timer at this and need some advice. Over the years I have acquired lots of donated track from people who heard I wanted to build a train layout in retirement. I now have a hodge podge collection of brass track (mostly Atlas, Tyco, Lionel and some stamped just made in Italy or Yugoslavia), and what I'm told is silver steel track (mostly Life Like, but a few Bachman) because the track has been sitting in the attic since 1990 and would not be silver nickel . I am getting close to the point where I will be laying the road bed and anchoring the track to it. My question with regards to the brass track - is there any problem with mixing and matching brass track from different venders, or should I just use one brand kind?

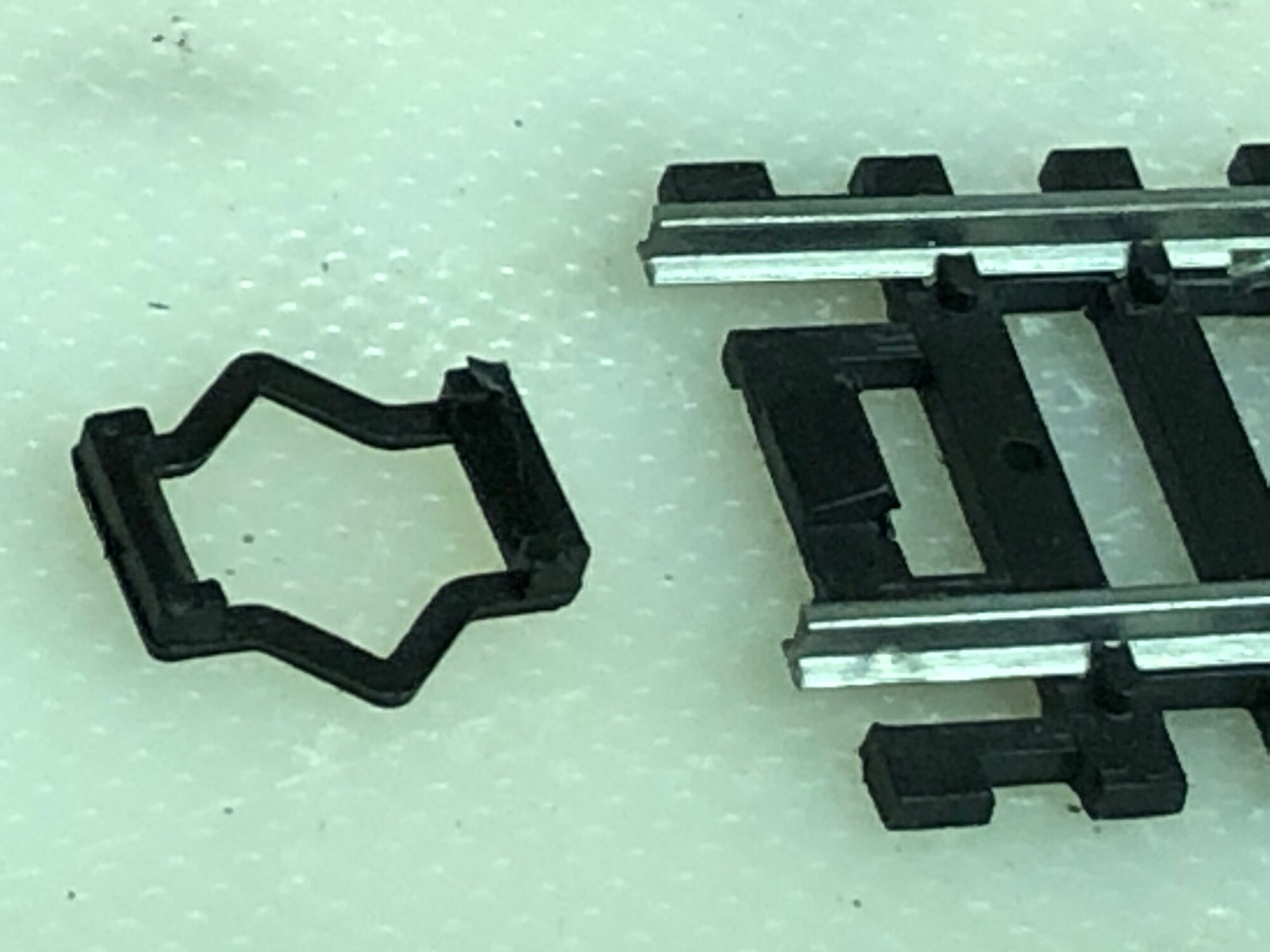

My second question is what are the pro and cons of using the silver steel over the brass? I ask this because I have almost enough Life Like track to complete the track circuit and I like the little locking tabs for keeping the track connected while I'm moving it around and not having to reconnect sections that pull apart. But I am short some pieces and locking tabs to complete the layout if I decide to go that way. Does anyone know where I can find additional Life Like track segments and locking tabs (see photos)? Can new newer silver nickel track be used to fill in gaps?

Appreciate your sharing your experience and advice on this matter before I fully commit to brass or the steel.

My second question is what are the pro and cons of using the silver steel over the brass? I ask this because I have almost enough Life Like track to complete the track circuit and I like the little locking tabs for keeping the track connected while I'm moving it around and not having to reconnect sections that pull apart. But I am short some pieces and locking tabs to complete the layout if I decide to go that way. Does anyone know where I can find additional Life Like track segments and locking tabs (see photos)? Can new newer silver nickel track be used to fill in gaps?

Appreciate your sharing your experience and advice on this matter before I fully commit to brass or the steel.