I've created a YouTube video showing you how to make Homabed: How to Make Homabed

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to Make Homabed

- Thread starter wesno

- Start date

ModelRailroadForums.com is a free Model Railroad Discussion Forum and photo gallery. We cover all scales and sizes of model railroads. Online since 2002, it's one of the oldest and largest model railroad forums on the web. Whether you're a master model railroader or just getting started, you'll find something of interest here.

You will need a good shop vacuum to go with it, something at least 6 hp to provide good suction. Use a bag and filter on the shop vacuum, although there won't be a whole lot of dust in it. You will also need a hose to run from the saw to the vacuum, a short hose from the Dustopper to the vacuum is included. You'll also need to get a plastic 5 gallon bucket while at Home Depot.

It works pretty good. Not as well as professional built in dust collection system, but it does a pretty good job. The bucket does tend to tip over, but I put about 5 pounds of weight in the bottom, and now it's pretty stable. All in all, I recommend it.

Remember that you produce a large VOLUME, but not POUNDS, of dust. So, plan on getting as big of dust collecting bin as you can.

Affiliate Disclosure: We may receive a commision from some of the links and ads shown on this website (Learn More Here)

That is an awesome video too!

Do you think that a thin kerf blade would do as good?

Do you think that a thin kerf blade would do as good?

Last edited:

Even though I use 2 types of saws in the video, I'm assuming you are referring to the table saw blade. I use a table saw with a 1/8" kerf to make the 4 basic cuts. Then I use a scroll saw with a pretty thin kerf blade to cut the slits. A 1/8" table saw blade kerf is pretty standard. Thus, the specific instructions calls that out. However, you could use a narrower blade if you wished or if you already had one. I see no advantage or disadvantage to using one that was thinner. I don't think the instructions would need to be altered at all since you are taking measurements from the fence to the saw blade.

Thanks, I was thinking that a more narrow table saw blade would NOT produce quite as much "dust" as I do not have a dust collector.

flyboy2610

Loveably weird

Sherrel, I did not have a dust collector for a long time either. Then I bought one of these: https://www.homedepot.com/p/Dustopp...ia-with-2-5-in-Hose-36-in-Long-HD12/302643445Thanks, I was thinking that a more narrow table saw blade would NOT produce quite as much "dust" as I do not have a dust collector.

You will need a good shop vacuum to go with it, something at least 6 hp to provide good suction. Use a bag and filter on the shop vacuum, although there won't be a whole lot of dust in it. You will also need a hose to run from the saw to the vacuum, a short hose from the Dustopper to the vacuum is included. You'll also need to get a plastic 5 gallon bucket while at Home Depot.

It works pretty good. Not as well as professional built in dust collection system, but it does a pretty good job. The bucket does tend to tip over, but I put about 5 pounds of weight in the bottom, and now it's pretty stable. All in all, I recommend it.

Thanks, Flyboy, for the suggestion. I have "most" of the makings except for the thingamajig it'self.

I'm getting to the age where I had just rather make do with what I already have vs buying more stuff - but, I will take a look at your suggestion. Meanwhile, if i can locate some scrap pieces of homasote down at the depot - I'll just open the garage door, roll the saw to the opening, and "dust" away!

I built a layout many years ago using 1/2 inch ply cookie cutter on risers with 1/2 inch homasote for roadbed and hand-laid track. (sure wish now that I had not sold my KD Spiker) Mine was not beveled on the edge - my bevel was plaster!

I'm getting to the age where I had just rather make do with what I already have vs buying more stuff - but, I will take a look at your suggestion. Meanwhile, if i can locate some scrap pieces of homasote down at the depot - I'll just open the garage door, roll the saw to the opening, and "dust" away!

I built a layout many years ago using 1/2 inch ply cookie cutter on risers with 1/2 inch homasote for roadbed and hand-laid track. (sure wish now that I had not sold my KD Spiker) Mine was not beveled on the edge - my bevel was plaster!

A narrower table saw blade will reduce the amount of dust simply because you are removing less material but it will still tend to spray everywhere.Thanks, I was thinking that a more narrow table saw blade would NOT produce quite as much "dust" as I do not have a dust collector.

I've not tried that. I know it is quite feasible since doing so actually requires you to perform one less step: cutting the bevel. I've read that some people prefer that style because it lets the ballast "fall" at a more realistic angle. Personally, I like using the 45 degree bevel because it requires less ballast material and the ballast is a more uniform thickness. I'd be concerned with making sure I got enough 50/50 glue/water into the thicker area next to the roadbed to make sure it stuck adequately. But, yes, this is a good alternative.Have you ever tried making the 1/8 thick roadbed (without the shoulder angle)?

Very good information. There are a lot of very good dust collection systems which will fill the bill and aren't as big or as expensive as the one I showed in the video. You may find some YouTube videos saying you can make yours for just a few bucks but I would do some research and find a moderately priced system that you can run off your shop vac. Be prepared to do a lot of reading and soul searching before you make your decision. The choices are endless and opinions vary widely. Bottom line: you need some dust collection but you don't need to break the bank.Sherrel, I did not have a dust collector for a long time either. Then I bought one of these: https://www.homedepot.com/p/Dustopp...ia-with-2-5-in-Hose-36-in-Long-HD12/302643445

You will need a good shop vacuum to go with it, something at least 6 hp to provide good suction. Use a bag and filter on the shop vacuum, although there won't be a whole lot of dust in it. You will also need a hose to run from the saw to the vacuum, a short hose from the Dustopper to the vacuum is included. You'll also need to get a plastic 5 gallon bucket while at Home Depot.

It works pretty good. Not as well as professional built in dust collection system, but it does a pretty good job. The bucket does tend to tip over, but I put about 5 pounds of weight in the bottom, and now it's pretty stable. All in all, I recommend it.

Remember that you produce a large VOLUME, but not POUNDS, of dust. So, plan on getting as big of dust collecting bin as you can.

AmtrakCr74108

Active Member

I like the idea of the dust collector but what do you use for the table saw? Maybe a picture?Sherrel, I did not have a dust collector for a long time either. Then I bought one of these: https://www.homedepot.com/p/Dustopp...ia-with-2-5-in-Hose-36-in-Long-HD12/302643445

You will need a good shop vacuum to go with it, something at least 6 hp to provide good suction. Use a bag and filter on the shop vacuum, although there won't be a whole lot of dust in it. You will also need a hose to run from the saw to the vacuum, a short hose from the Dustopper to the vacuum is included. You'll also need to get a plastic 5 gallon bucket while at Home Depot.

It works pretty good. Not as well as professional built in dust collection system, but it does a pretty good job. The bucket does tend to tip over, but I put about 5 pounds of weight in the bottom, and now it's pretty stable. All in all, I recommend it.

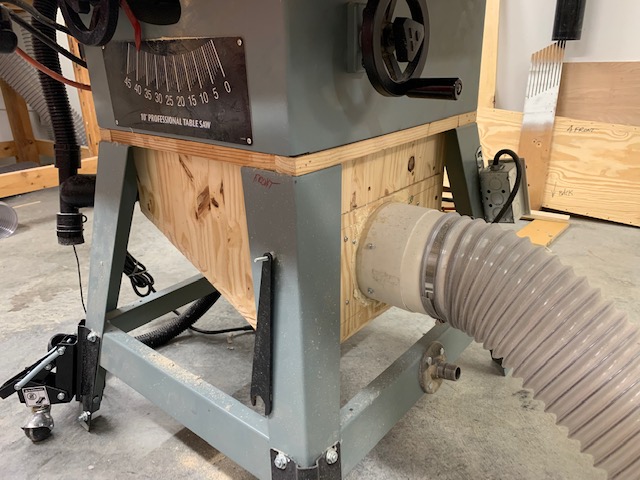

I'm assuming you are asking how I collect the dust at the table saw and feed it to the dust collector. If you buy a nice table saw these days, you might be fortunate enough to have it come with some dust collection ports built in. My saw is decades old, which is a common state for many of us. As for collecting dust below the saw, when you don't have any (or good enough) built-in ports, there are many ideas on YouTube about this issue. I chose to use the design shown in this video: How to Make a Table Saw Dust Collector Box

The basic design is quite sound. The best aspect of this design is the sloping floor. This makes sure the dust naturally gravitates to the dust port. I simplified mine a bit from the design shown in the video but the basic idea is quite good. The only bad part, which really can't be avoided, is you need to take your saw off its base, build the box and then put it back on. It's a bit of a trick to put the saw back on and have all your holes line up. A photo of how my final product looks is attached.

Another thing to consider is capturing the dust that wants to shoot out the top of your blade. SharkGuard makes a very good product that attaches to practically any brand saw and you then attach your hose to the dust port and you're good to go. Here's a link to their site: SharkGuard This works great if your cut is sufficiently wide. Since I do many fairly narrow cuts, I fashioned a special bracket that I mount to the fence with t-bolts and the bracket allows me to then mount the SharkGuard onto it. A photo is attached; I apologize for 90 degree rotation issue as the upload feature of this site seemed to want to rotate the photo no matter what I did.

The basic design is quite sound. The best aspect of this design is the sloping floor. This makes sure the dust naturally gravitates to the dust port. I simplified mine a bit from the design shown in the video but the basic idea is quite good. The only bad part, which really can't be avoided, is you need to take your saw off its base, build the box and then put it back on. It's a bit of a trick to put the saw back on and have all your holes line up. A photo of how my final product looks is attached.

Another thing to consider is capturing the dust that wants to shoot out the top of your blade. SharkGuard makes a very good product that attaches to practically any brand saw and you then attach your hose to the dust port and you're good to go. Here's a link to their site: SharkGuard This works great if your cut is sufficiently wide. Since I do many fairly narrow cuts, I fashioned a special bracket that I mount to the fence with t-bolts and the bracket allows me to then mount the SharkGuard onto it. A photo is attached; I apologize for 90 degree rotation issue as the upload feature of this site seemed to want to rotate the photo no matter what I did.

D&J RailRoad

Professor of HO

After all that expense and the time to make each section, how much do ya save over buying a box of the cork roadbed?

AmtrakCr74108

Active Member

Thank you. That is exactly what I was looking for to see about adding one to my old Craftsman.I'm assuming you are asking how I collect the dust at the table saw and feed it to the dust collector. If you buy a nice table saw these days, you might be fortunate enough to have it come with some dust collection ports built in. My saw is decades old, which is a common state for many of us. As for collecting dust below the saw, when you don't have any (or good enough) built-in ports, there are many ideas on YouTube about this issue. I chose to use the design shown in this video: How to Make a Table Saw Dust Collector Box

The basic design is quite sound. The best aspect of this design is the sloping floor. This makes sure the dust naturally gravitates to the dust port. I simplified mine a bit from the design shown in the video but the basic idea is quite good. The only bad part, which really can't be avoided, is you need to take your saw off its base, build the box and then put it back on. It's a bit of a trick to put the saw back on and have all your holes line up. A photo of how my final product looks is attached.

Another thing to consider is capturing the dust that wants to shoot out the top of your blade. SharkGuard makes a very good product that attaches to practically any brand saw and you then attach your hose to the dust port and you're good to go. Here's a link to their site: SharkGuard This works great if your cut is sufficiently wide. Since I do many fairly narrow cuts, I fashioned a special bracket that I mount to the fence with t-bolts and the bracket allows me to then mount the SharkGuard onto it. A photo is attached; I apologize for 90 degree rotation issue as the upload feature of this site seemed to want to rotate the photo no matter what I did.

View attachment 46517View attachment 46519

I have not tried making this exact profile. However, it would be super simple because putting on the shoulder angle, and keeping all pieces the exact same width, is the hard part. I can dial my table saw down to 1/8" and it would be repeatable. So, you would cut your big sheets into manageable pieces, cut them to 1/8" wide and then cut to the desired width.Have you ever tried making the 1/8 thick roadbed (without the shoulder angle)?

There's no question that I'm spending more money and time than using cork. So, why bother? Because of the advantages that I believe homasote offers over cork. I'm willing to make the investment. If one agrees that the tradeoffs are valid, then I'm supplying a path to get some pretty good looking homasote roadbed, even though it's not commercially available any longer.After all that expense and the time to make each section, how much do ya save over buying a box of the cork roadbed?

Since you are set-up to make Homabed, would you consider doing so for me? I would only want the cut road bed and would put the kerfs in for bending myself. What would the cost be? I don't have a table saw nor a dust collection system, so I am really interested!!! PM me if you are interested. I would need about 140 linier feet of road bed.

Last edited:

I am not willing to make any homabed for others for many reasons including: liability, taxes (and the hassle of paying them), setting up for mass production, unknown cost of shipping (or more precisely my lack of desire to calculate shipping on such odd size stuff), etc. I'm retired and have no desire to spend my time doing a second career. I made the video to help others get to where I am. I was hesitant to post the video and this reference to it because I thought others might want to buy the finished product (I certainly would) but I posted anyway simply to share knowledge. Basically, I'm not keen to spending my time making the stuff for hours on end. Thanks for your interest as it never hurts to ask.

Affiliate Disclosure: We may receive a commision from some of the links and ads shown on this website (Learn More Here)