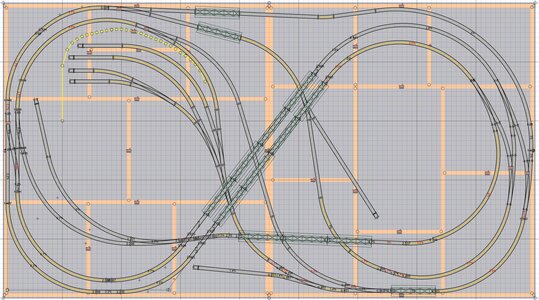

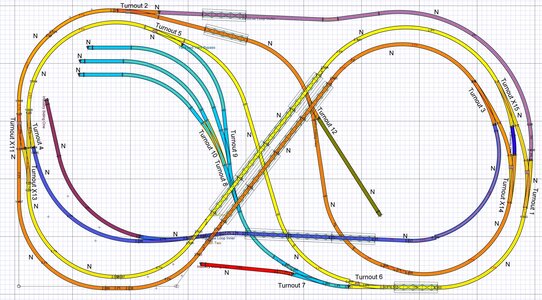

Hello everyone. Just some updates on the layout.

After a lot of research and looking around and researching some more, I decided to go with MegaPoints Controllers out of the UK for my turnout controls. I purchased an Arduino Mega and an Arduino Motor Shield that I intended to use for this purpose, but got cold feet and decided for now I don't want to dive into Arduino code, I want something more plug-n-play, hence the MegaPoints. I plan on using Arduino in the future for other purposes.

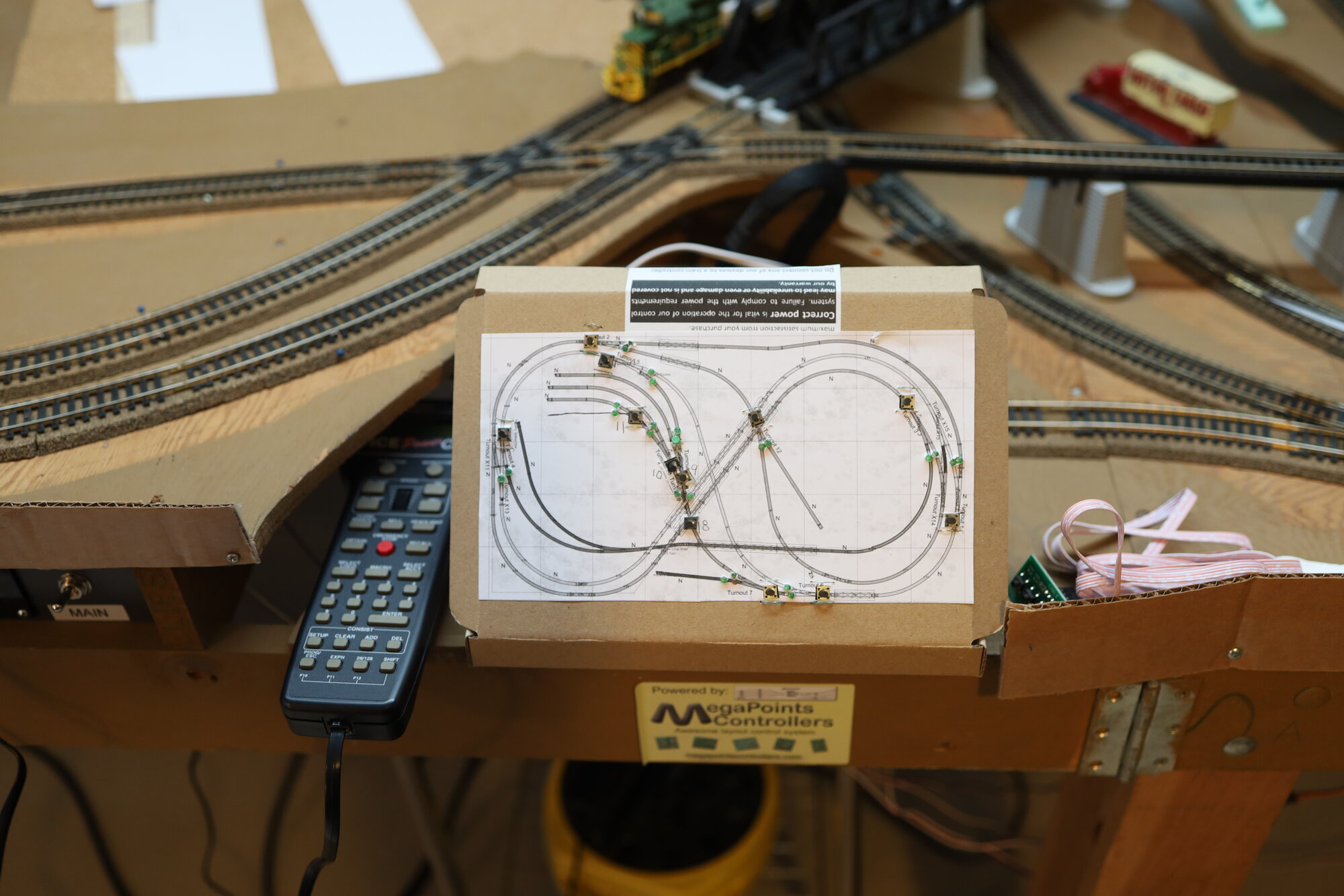

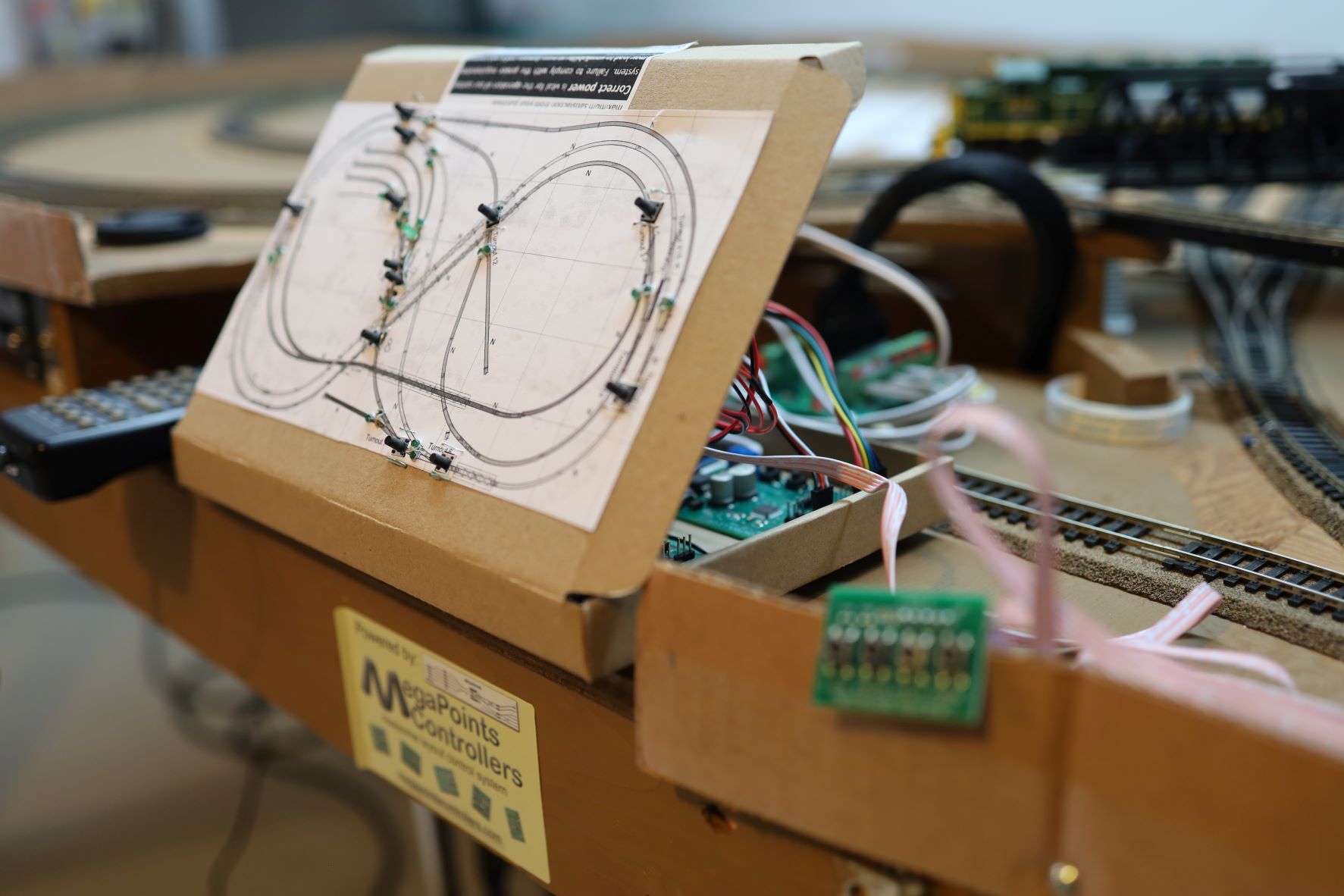

I did purchase the DCC interface from MegaPoints, but other than installing it into the "control panel", I haven't done anything with it yet.

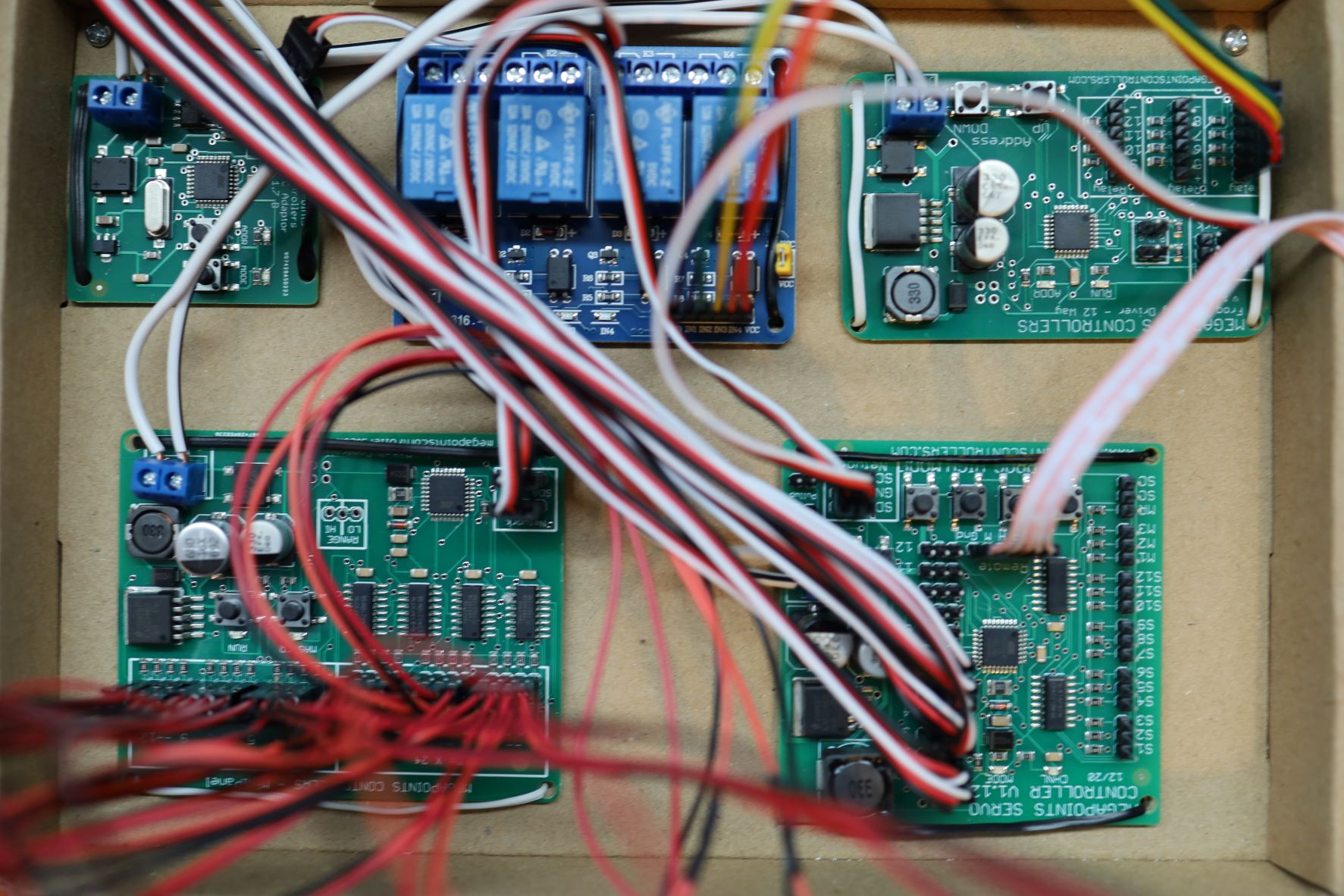

Here are some photos of the "control panel" I made, using the MegaPoints boards. I don't have much room around the layout, and I want to keep the control panel as small as possible, so I just used the box that the MegaPoints items were shipped in to build this mock-up to give me an idea of how small I can go. This first go-around is a little too small, I need to go 10-20% bigger so I have enough room for the indicator LEDs. But this confirms that I can go small enough that the panel can fit on my layout. I just have to come up with a design and then build it. I've thought about maybe incorporating it into the roof of a building. But not sure if that's a little too goofy or not. Still pondering.

I purchased the Frog Relay/Driver Board and the Relay board from MegaPoints. I have old Atlas Custom Line turnouts on my layout, and they act inconsistently. There are two #6 turnouts, and they cause problems with the DCC because the frog is plastic. I get stalled locomotives when I'm going slow and pauses when I'm running the locos a little faster. Faster still, then no problems. I have a solution that I found on the YouTubes in mind for that problem that I am going to attempt. The other turnouts are all #4s, which have pot metal frogs which can't be soldered, but again YouTubes offer a solution for that which I am going to try. I'm not convinced though that there isn't some other issue with all the turnouts because I'll get indications of a short at times (the power light on the NEC DCC panel will turn off and on as a loco passes over the turnout), so I have to dig a little deeper on the turnout issues. But normally I can run without interruption, I'd just like to get these to behave all the time.

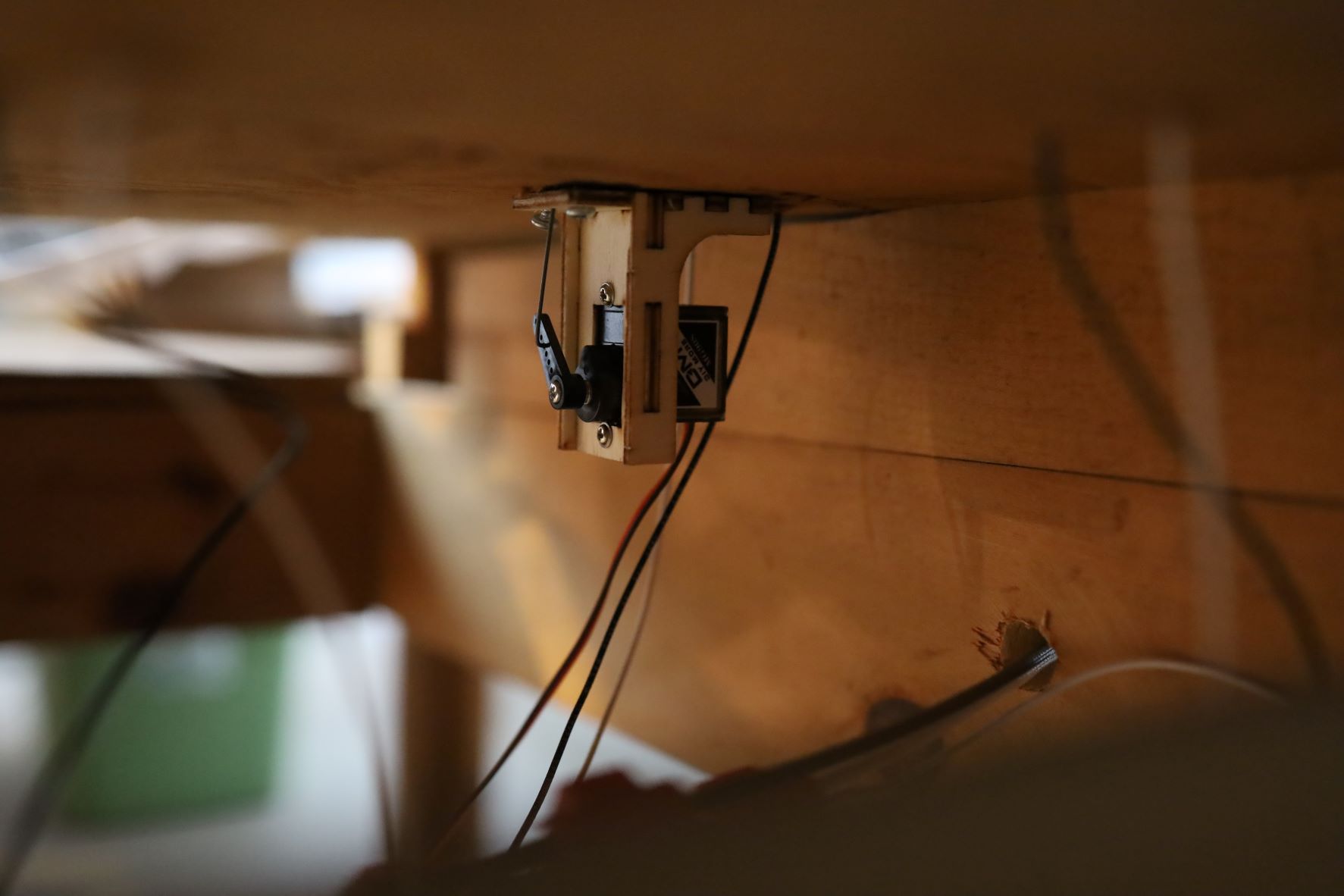

Here's a turnout servo using the MegaPoints servo mount. The mounts are very inexpensive, around $2.50 - $3.00 each with shipping. They are laser cut in wood ply material (not solid wood), and are advertised as if you can just pop them out of the "sheet" they are printed on, but in reality most of them needed some extra cutting along the laser cut lines, or else they would break. The holes for mounting them to the underside of the layout (plywood, in my case) are too small and must be enlarged or else the material will break and peel away around the holes. Once the shapes are punched out of their sheet, you glue the pieces together with superglue. All in all, they work fine and I would use them again. I see in this picture one of my mounting screws isn't quite set all the way. Oops. Working under a layout at my age is a PITA. I still have 5 more servos to place.

Here's a shot at my unfinished mountain attempt. Here I'm just trying to get a picture in my mind of what the scenery is going to look like and get some idea of where to go with this. The scenery part of it has been a logjam in my mind, so just trying to kick some ideas around. This is a very crude mock-up. I'm hoping to come up with a way to place the mountains such that they can be lifted off if the layout ever has to be moved, without it looking like it is a mountain that can be lifted off.

Here's a practice attempt at a bridge abutment out of Lowe's green foam panel:

And lastly, here's a somewhat overall view of the layout:

That's all for now. I'll post some further updates as I go along. At the moment, fishing is interfering with my railroad hobby. Or maybe it is the other way around.