You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Flat Car Decking

- Thread starter Greg@mnrr

- Start date

ModelRailroadForums.com is a free Model Railroad Discussion Forum and photo gallery. We cover all scales and sizes of model railroads. Online since 2002, it's one of the oldest and largest model railroad forums on the web. Whether you're a master model railroader or just getting started, you'll find something of interest here.

Other than vehicle flats with chain tie downs troughs in the deck I've NEVER seen cars with boards running fully lengthwise..

Another thing to be aware of is that a lot of more modern flats actually do not have wood floors at all, but nailable steel floors. This looks likes boards, but is actually steel decking, and blocking can be nailed to it by driving the nails into the seams. https://patents.google.com/patent/US2900055A/en

Sherrel, yes it sure helps. Now I just just need help cutting all those boards.

And, thanks Chris for the info on new flat cars.

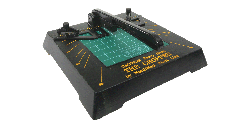

I know that Santa is bringing me a NorthWest Chopper and it's under the tree.

Greg

There is also an unevenness to the deck as well!

Found this U-tube ...

Affiliate Disclosure: We may receive a commision from some of the links and ads shown on this website (Learn More Here)

Have you looked into LaserKit's decks? http://www.laserkit.com/decksho2.htm (towards the middle of the page).

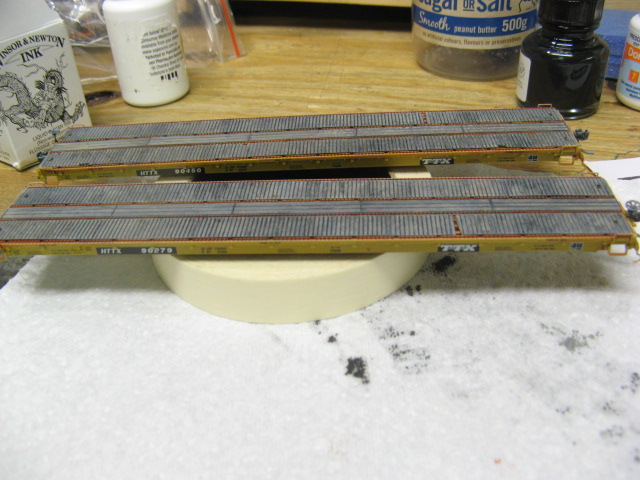

This is an example of Intermountain Trains wood deck flat OTTX cars that have been weathered, There are more somewhere on this site, The only fault with theirs is they didn't run the grain on the center strip longitudinally to match the etching

This is a plastic painted deck MTH flat car, weathered with paints. One of my early attempts, I have varied them with lighter greys, blues etc brushed lightly over in the direction of the grain with light flicking strokes while the base paint is still soft. Enhance the grooves between the boards with the sharp point of the back edge of a modelling knife first.

Last edited:

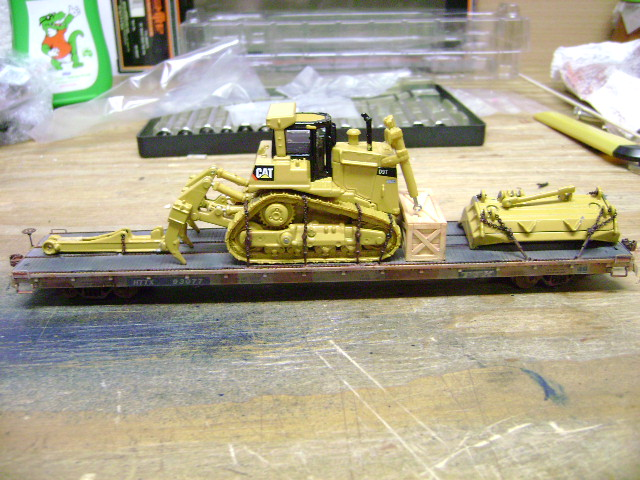

Norscot D9T on lightly weathered MTH flat

Best of my relocation the boards were 3x8 or 3x10.

Greg -- I did a little research and found that the newer 60 and plus length flats have 2x6 boards running lengthwise whereas the older 40 - 50 foot flats have the 3x8 x-ways on the deck!

Hope this helps.

Hope this helps.

If you go that way, you will have to be very careful not to allow any glue to rise up through the gaps or sides of the boards, especially onto the surface as it will prevent the stain penetrating, leaving unstained spots. Best to stain the boards all over first.Thanks guys for your input. I was purchased a NWSL chopper to cut the boards. Sherrel I think I'll go with the 3 X 8 boards and glue in place and then stain.

Greg

cv_acr

Well-Known Member

Greg -- I did a little research and found that the newer 60 and plus length flats have 2x6 boards running lengthwise whereas the older 40 - 50 foot flats have the 3x8 x-ways on the deck!

Hope this helps.

Other than vehicle flats with chain tie downs troughs in the deck I've NEVER seen cars with boards running fully lengthwise..

Another thing to be aware of is that a lot of more modern flats actually do not have wood floors at all, but nailable steel floors. This looks likes boards, but is actually steel decking, and blocking can be nailed to it by driving the nails into the seams. https://patents.google.com/patent/US2900055A/en

Last edited:

Greg@mnrr

Section Hand

Greg -- I did a little research and found that the newer 60 and plus length flats have 2x6 boards running lengthwise whereas the older 40 - 50 foot flats have the 3x8 x-ways on the deck!

Hope this helps.

Sherrel, yes it sure helps. Now I just just need help cutting all those boards.

And, thanks Chris for the info on new flat cars.

I know that Santa is bringing me a NorthWest Chopper and it's under the tree.

Greg

Last edited:

GREG -- Don't make them too perfect ... The 40/50 foot flats I have seen in person have a little unevenness to the edges! AND maybe even have a few broken boards and missing pieces?I know that Santa is bringing me NorthWest Chopper and its under the tree.

There is also an unevenness to the deck as well!

Found this U-tube ...

Last edited:

Just think of all the bolts you'll have to install.Excellent find. I like the color of the decking. I still have a couple of vintage bottles of "Age It" to weathered wood. I'll even use my pouce wheel to add bolt holes.

Thanks.

Greg

Really interesting video, especially for me with those views of the 60' wood deck, Heavy duty, which is what the MTH HO ones are. They are (or were when in production and only 2 runs in 10 years of them) made to a high quality. The detailing is/was extreme, even to the chainlock block notches visible in the video in the channels the blocks slide in, Their only problem was the use of all metal sprung truck frames with metal axles and metal wheels and insulation on one wheel only with a metal strip inserted inside the plastic lengthwise down the middle of the deck and the truck pivot screws (also metal) into that. The first run had well defined and easily seen insulators on that 1 only wheel. The 2nd run, they were hard to see and identify. In consequence many had had the trucks assembled with the insulators on opposite sides on the same truck, resulting in direct diagonal short circuits through the bolster which also melted the plastic on the pivot before it tripped the short protection. The first run had mostly "fallen flag" now, roadnames. but TTX and UP as well. The last run were all late class 1's but still TTX and UP as well if you see them for sale. They did them with Norscot Machinery as well. All came with packets of chains and tie downs. Real fiddly, I can tell you.GREG -- Don't make them too perfect ... The 40/50 foot flats I have seen in person have a little unevenness to the edges! AND maybe even have a few broken boards and missing pieces?

There is also an unevenness to the deck as well!

Found this U-tube ...

Affiliate Disclosure: We may receive a commision from some of the links and ads shown on this website (Learn More Here)